Three-dimensional frame reinforcement structure and construction method in large-volume masonry masonry column

A technology for strengthening structures and construction methods, applied in building maintenance, building components, building structures, etc., can solve problems such as changing structural components and reinforcement methods that cannot meet requirements, so as to improve vertical bearing capacity, reduce appearance damage, The effect of improving the overall seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

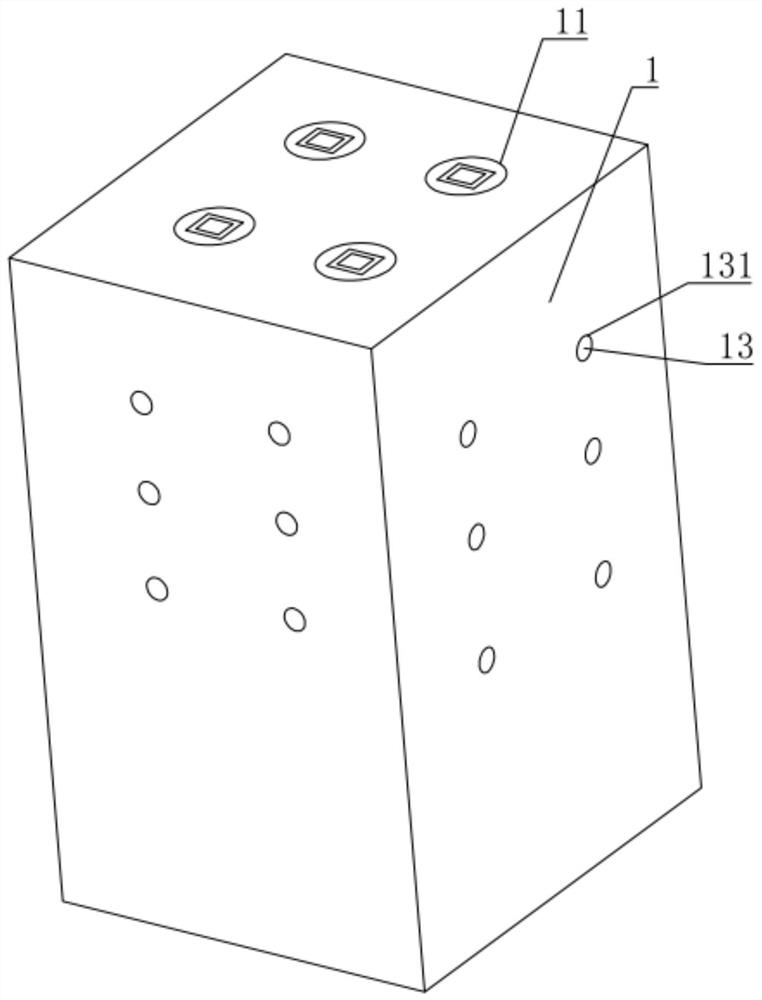

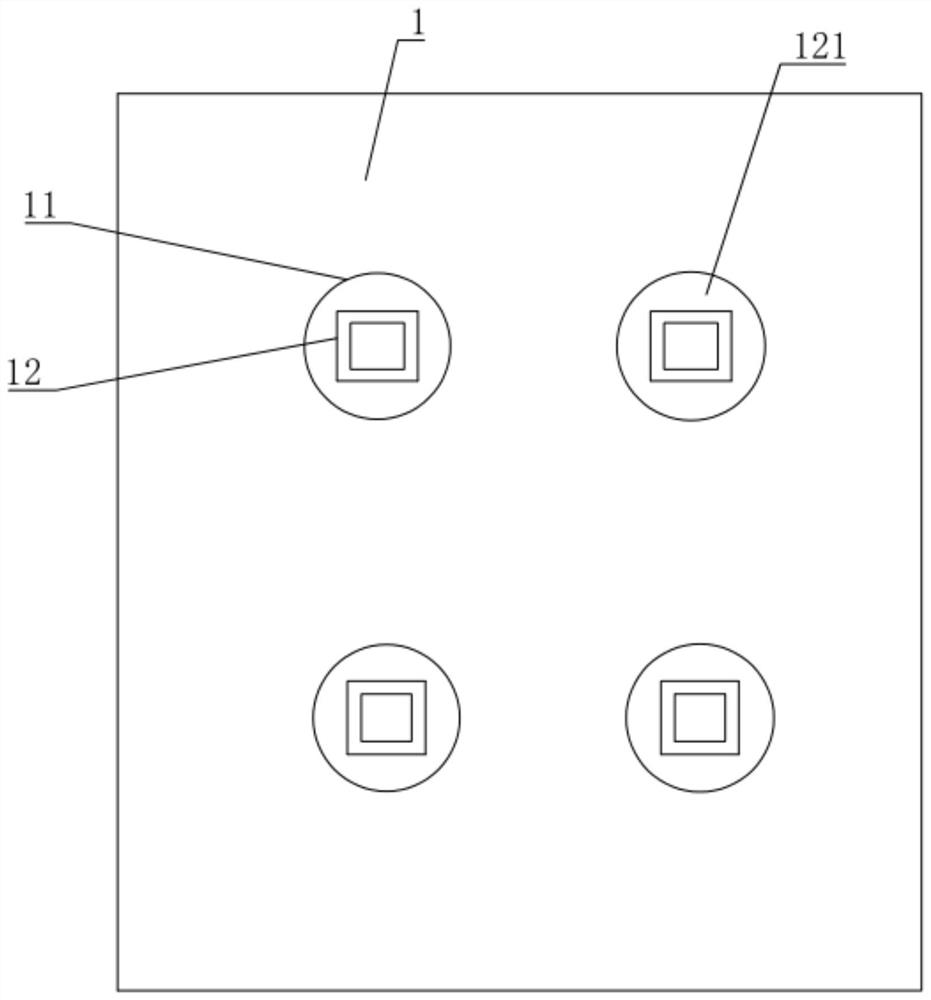

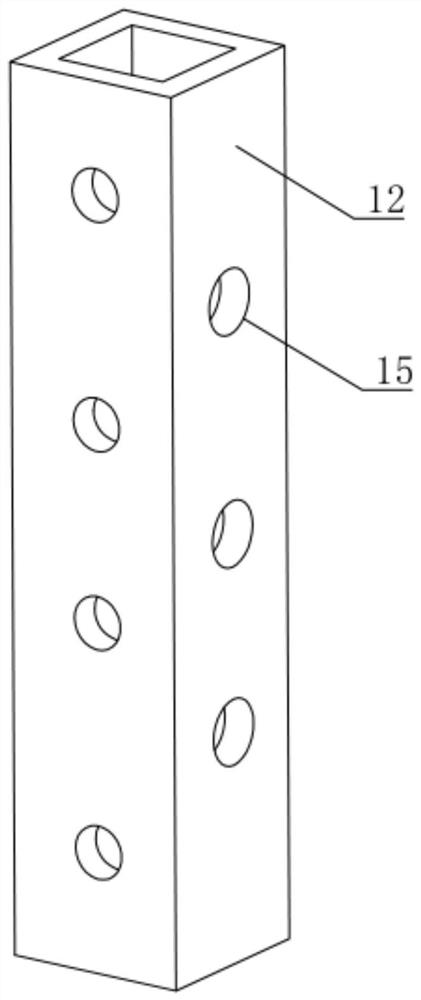

[0035] Embodiment 1: A three-dimensional frame reinforcement structure in a large-volume masonry column, such as figure 1 with figure 2 , including a number of parallel first fixing holes 11 set in the existing masonry member 1, square steel pipes 12 pierced in each first fixing hole 11, filling the outer wall of the square steel pipe 12 and the first fixing hole 11 The filling layer 121 between the walls and a number of bushing grouting anchors 13 that pass through the existing masonry member 1 and are perpendicular to the length direction of the square steel pipe 12. One end of each bushing grouting anchor 13 passes through the same plane. Each square steel pipe 12 in.

[0036] Such as figure 1 with figure 2, each square steel pipe 12 and each bushing grouting anchor 13 form a three-dimensional space frame, and the bushing grouting anchor 13 passes through the square steel pipe 12, and the volume of the bushing grouting anchor 13 expands after grouting, so that the bush...

Embodiment 2

[0044] Embodiment 2: a kind of construction method based on above-mentioned embodiment 1, as Image 6 , including the following steps, step 1, according to the vertical force and horizontal force borne by the existing masonry member 1 after reinforcement, determine the cross-sectional area and number of steel pipes required for reinforcement, and the spacing of grouting anchor rods 13 with bushings;

[0045] Step 2, determining the drilling distance and drilling position of the first fixing holes 11 on the top surface of the existing masonry member 1;

[0046] Step 3: Determine the drilling position of the side wall of the steel pipe according to the required spacing of the grouting anchor rods 13 with bushings, and drill the second fixing holes 131 alternately on adjacent surfaces;

[0047] Step 4. After the first fixing hole 11 is drilled, place the square steel pipe 12. The center of the square steel pipe 12 coincides with the drilling center of the first fixing hole 11, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com