Method for covering substrate having concave-convex surface by using PVC film and application

A technology of concave-convex surface and base material, applied in chemical instruments and methods, lamination, building components, etc., can solve the problems of pattern distortion, floating, sinking and shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

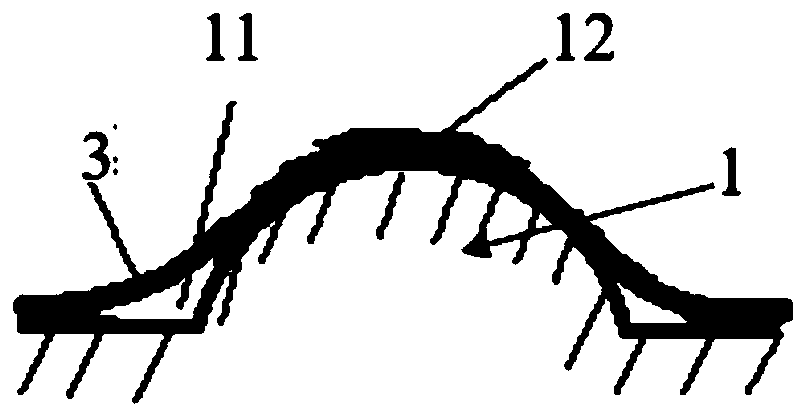

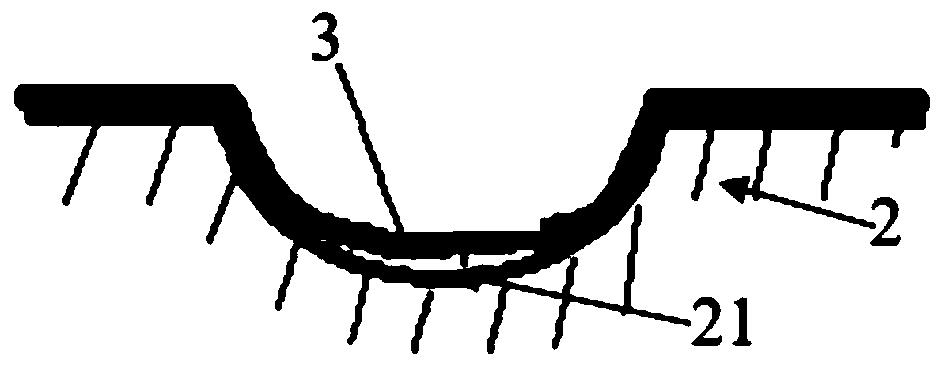

[0044]According to the inventor's in-depth research and analysis, it is found that the main cause of the floating phenomenon is that when the concave-convex base material surface is covered with PVC, the pressurized pressure or vacuum adsorption is not enough, and the ductility of the PVC film is relatively poor (there is a property of the PVC film material itself. The reason is also due to unreasonable process temperature control, etc.), and the PVC film elastically shrinks after covering the surface, resulting in floating. The main reason for the problem of pattern deformation, distortion and whitening is that the elastic ductility of PVC is not enough, and the external force is greater than the elastic range of the film, which leads to serious "local concentration" plastic deformation of PVC itself, resulting in the printed on the surface of PVC. The pattern is distorted and partially whitened. The main reason for the sinking and shrinking of the concave surface is that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com