Efficient self-centering rotary cutter

An automatic centering and rotary cutting machine technology, which is applied in the manufacture of thin wood chips, wood processing equipment, manufacturing tools, etc., can solve the problems of automatic centering of round logs, complex structure, poor quality of wood chips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

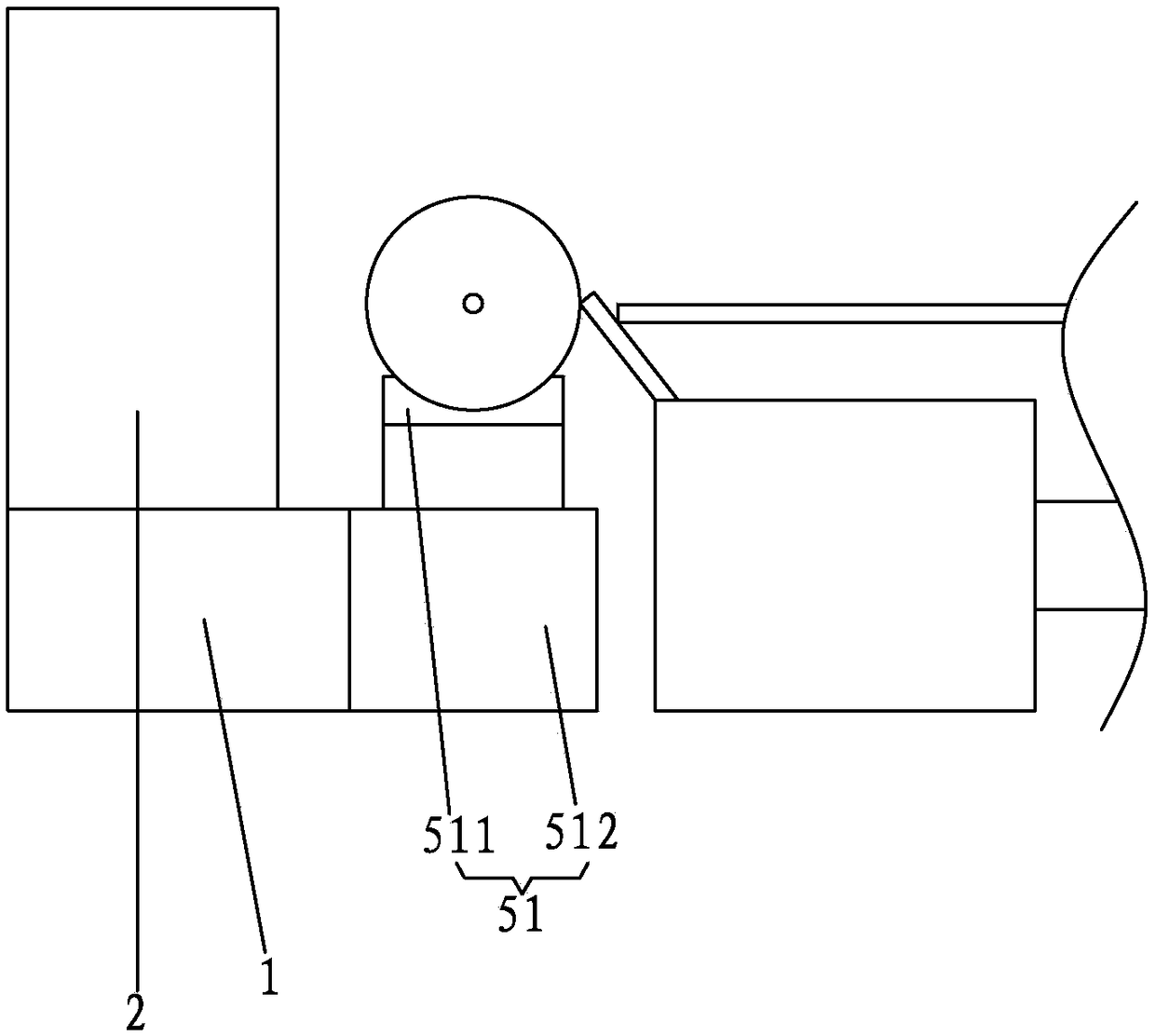

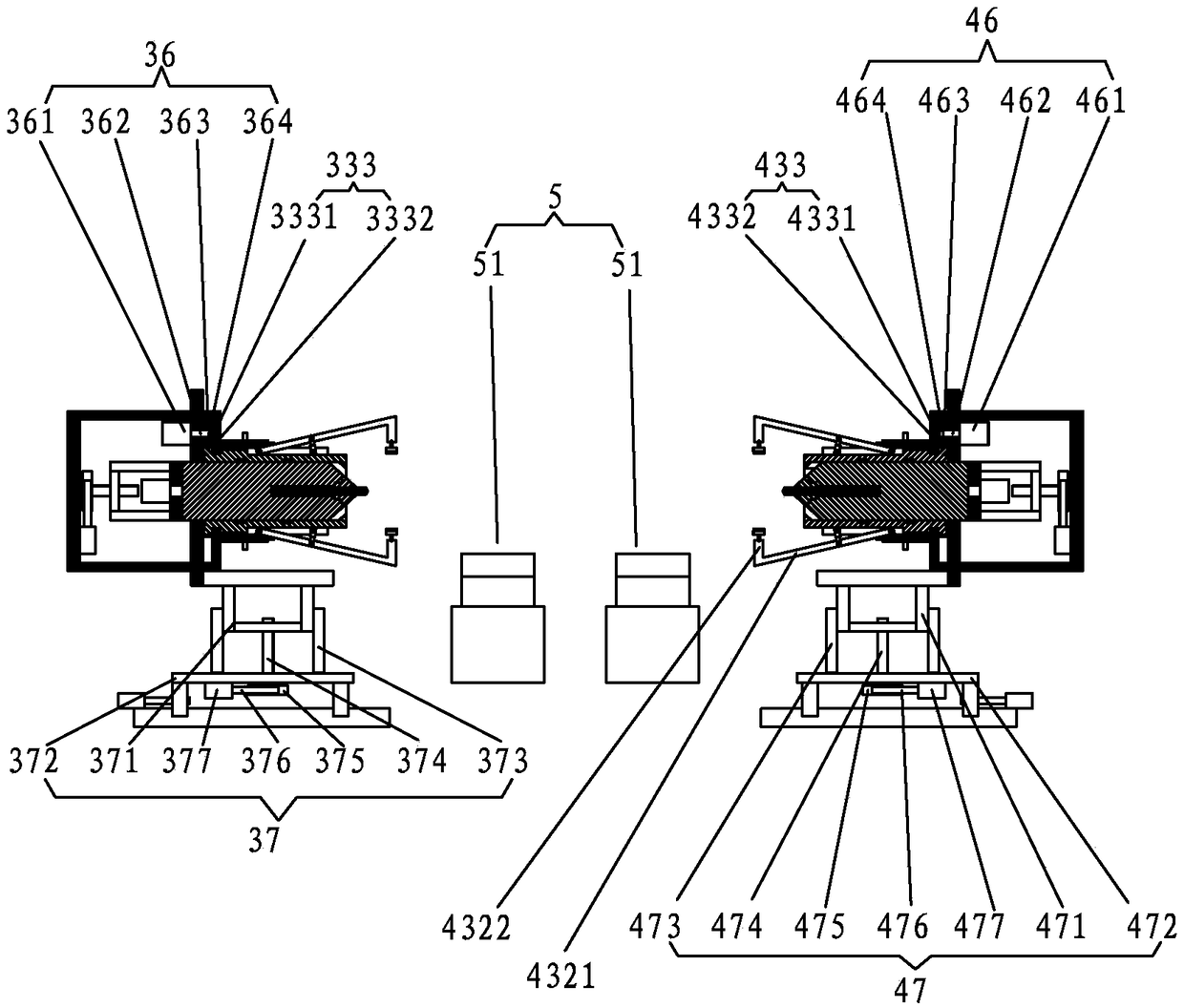

[0043] A kind of efficient automatic centering rotary cutting machine of the present invention, as Figure 1 to Figure 9 As shown, it includes a frame 1, a rotary cutting mechanism 2 and a clamping shaft arranged on the frame 1; the clamping shaft includes a first clamping part 3 at one end of the log, and a second clamping part 4 at the other end of the log ; Both the first clamping part 3 and the second clamping part 4 have a proximal end facing the direction of the log and a distal end facing the opposite direction; also include an initial support column 5 arranged under the log;

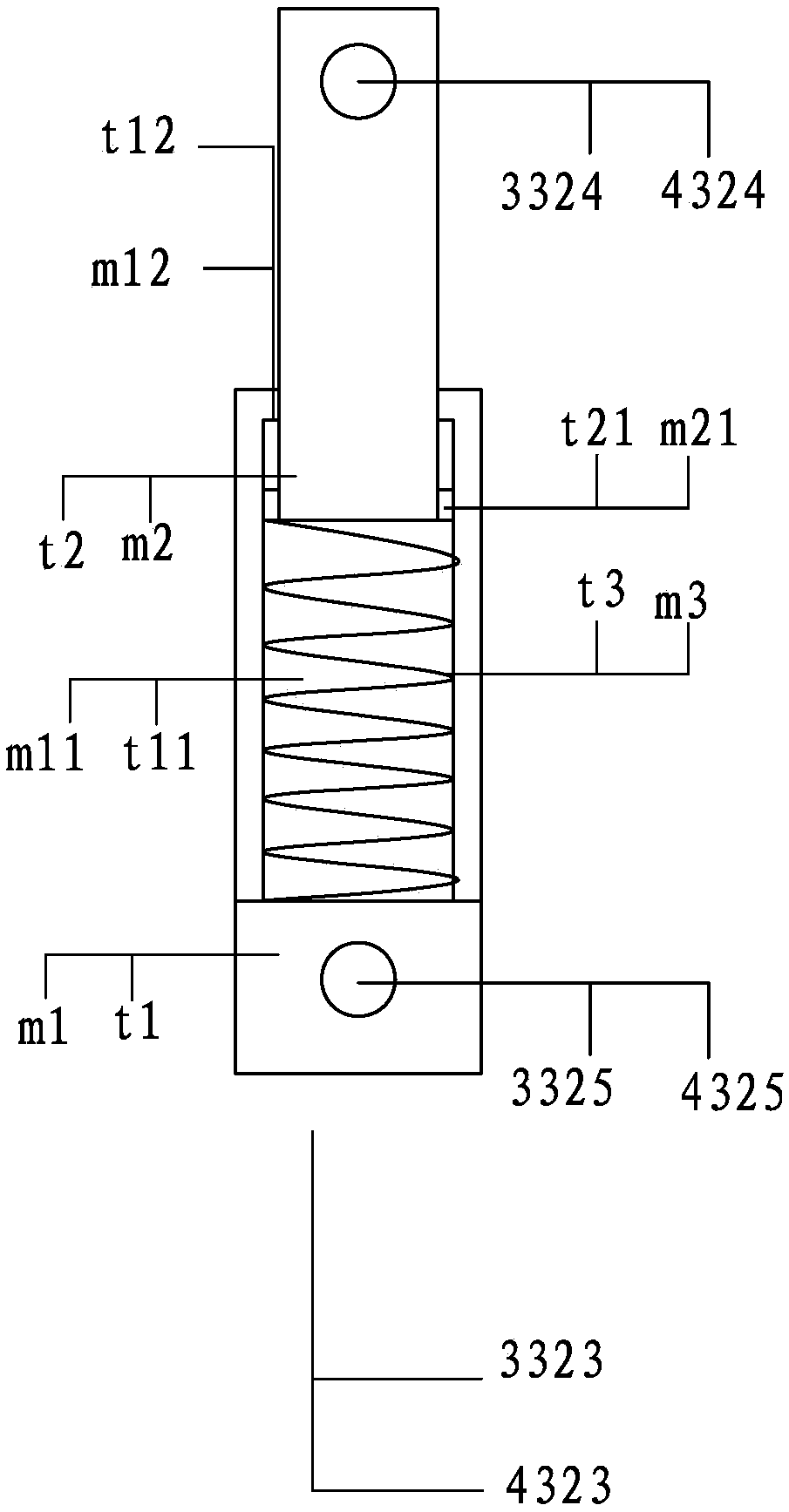

[0044] The first clamping part 3 includes a first main base plate 31 perpendicular to the log, a first positioning shaft mechanism passing through the first main base plate 31, and a first positioning sleeve mechanism sleeved outside the first positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com