Patents

Literature

31results about How to "Avoid cracks or even breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

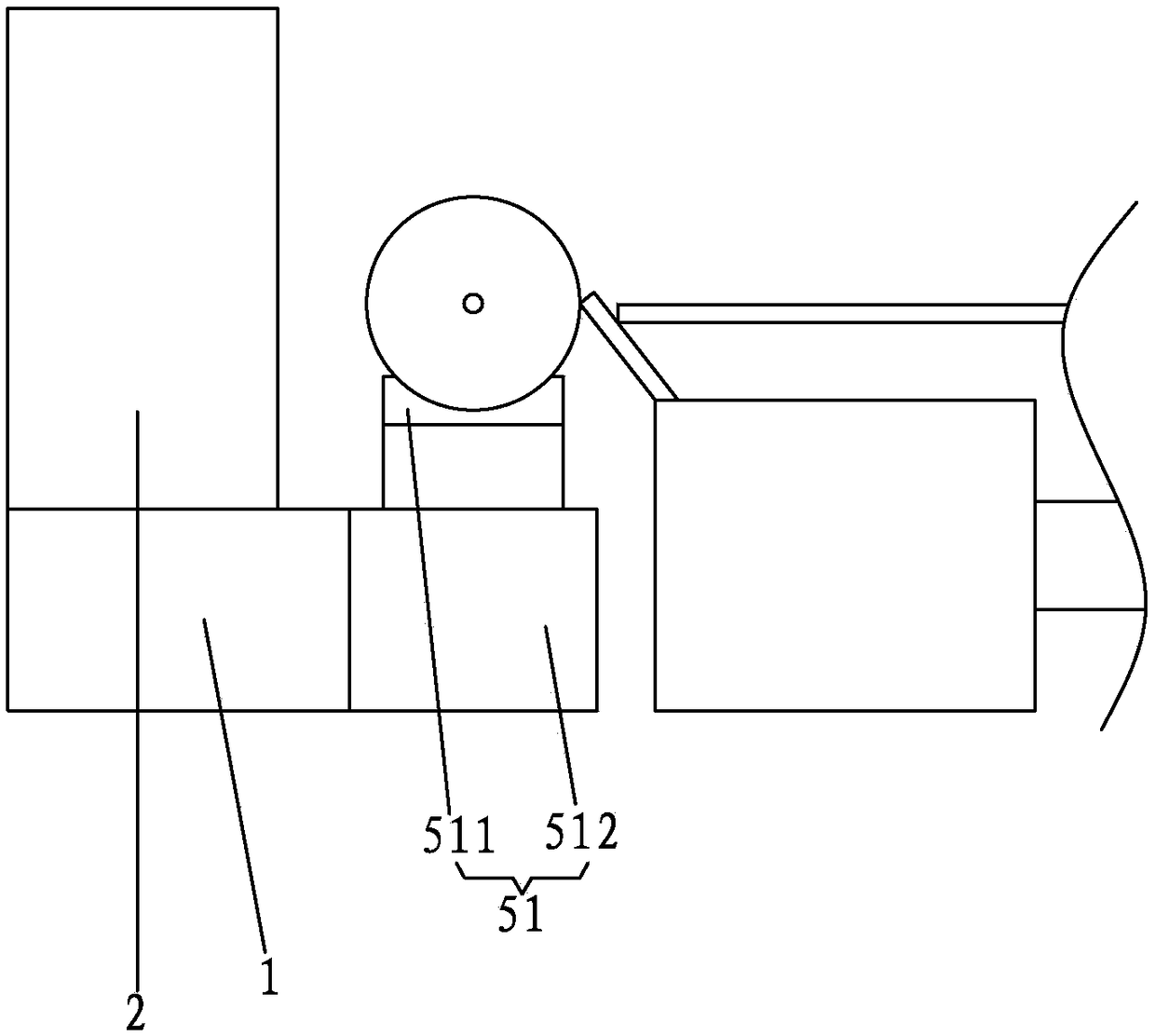

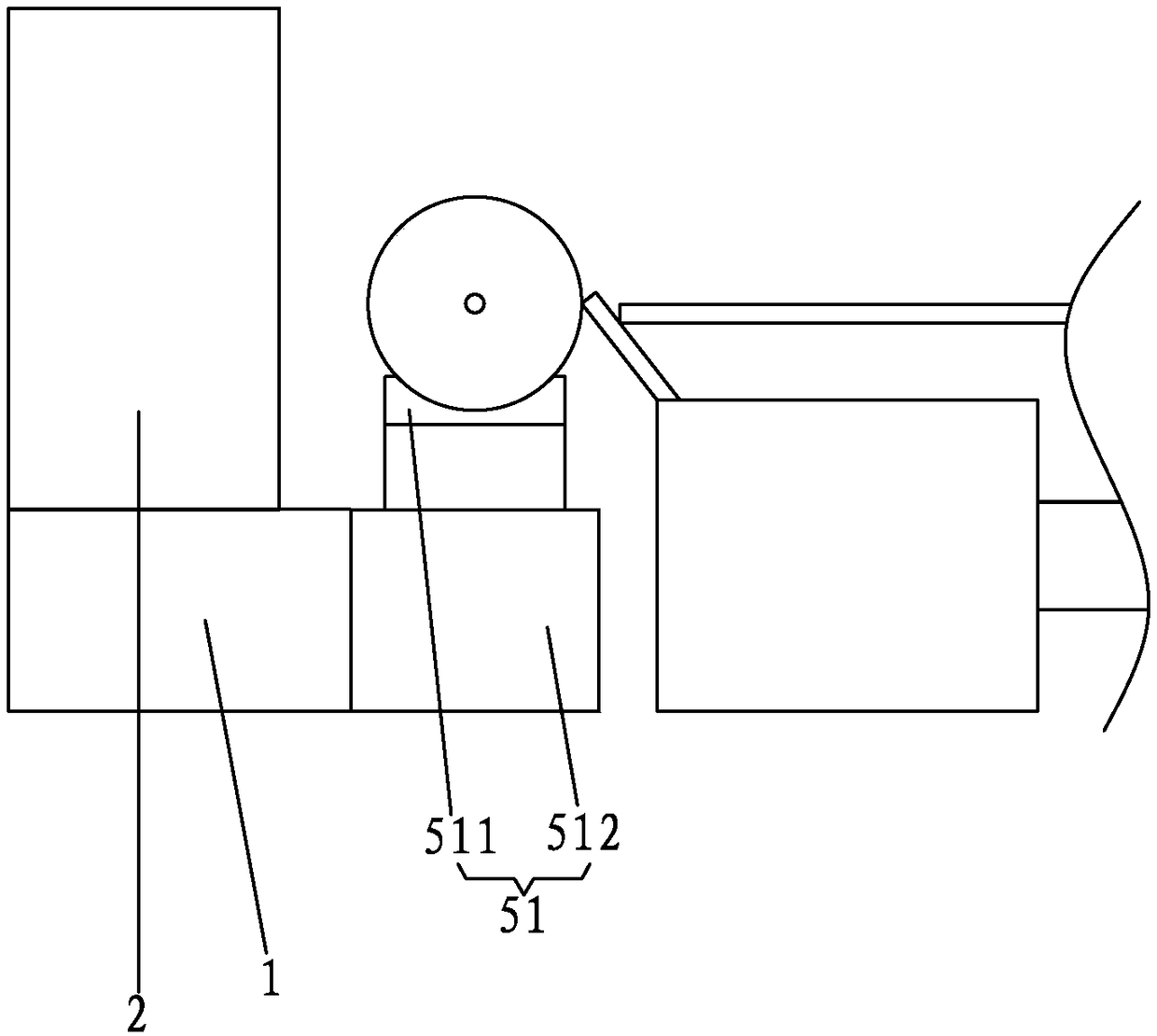

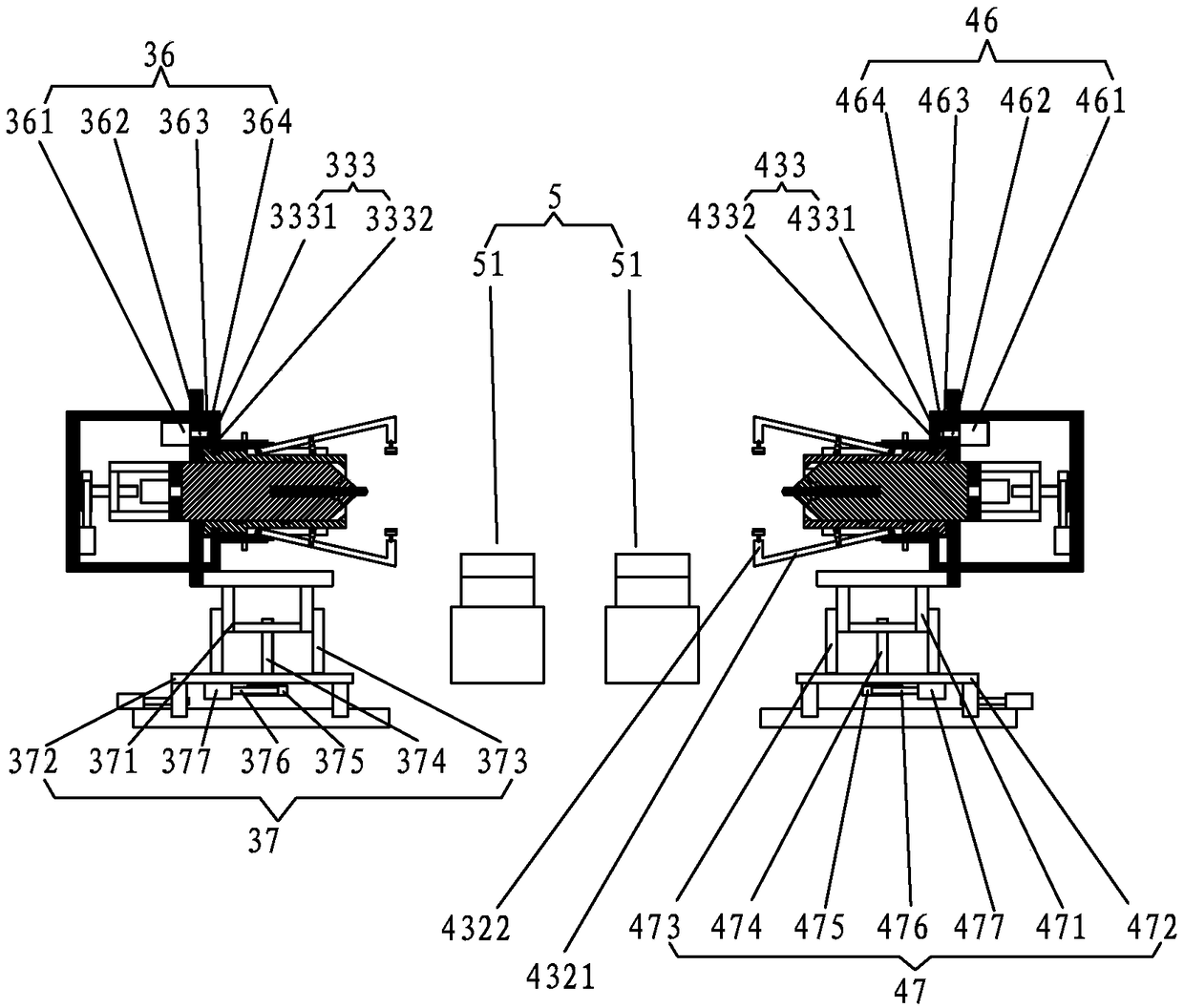

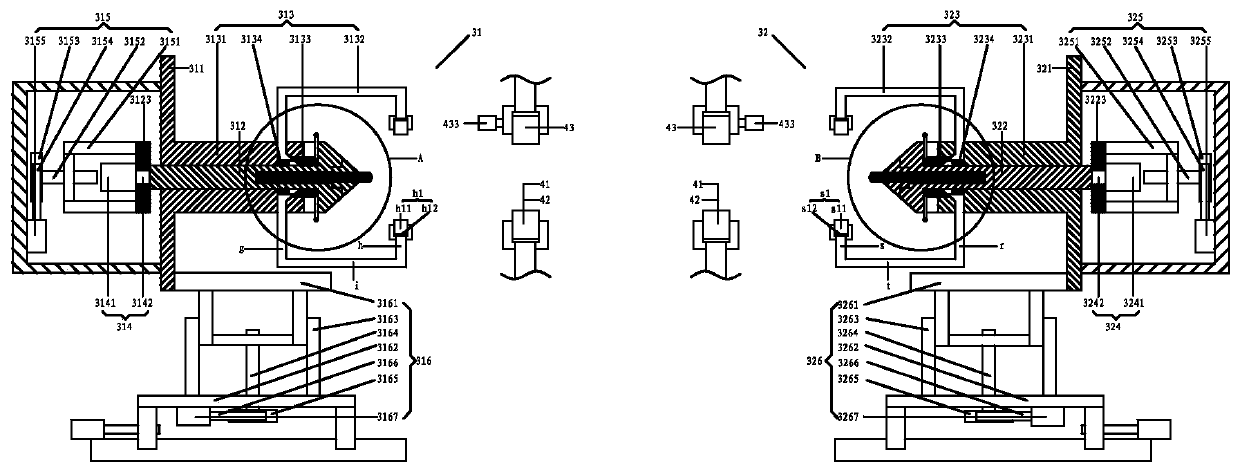

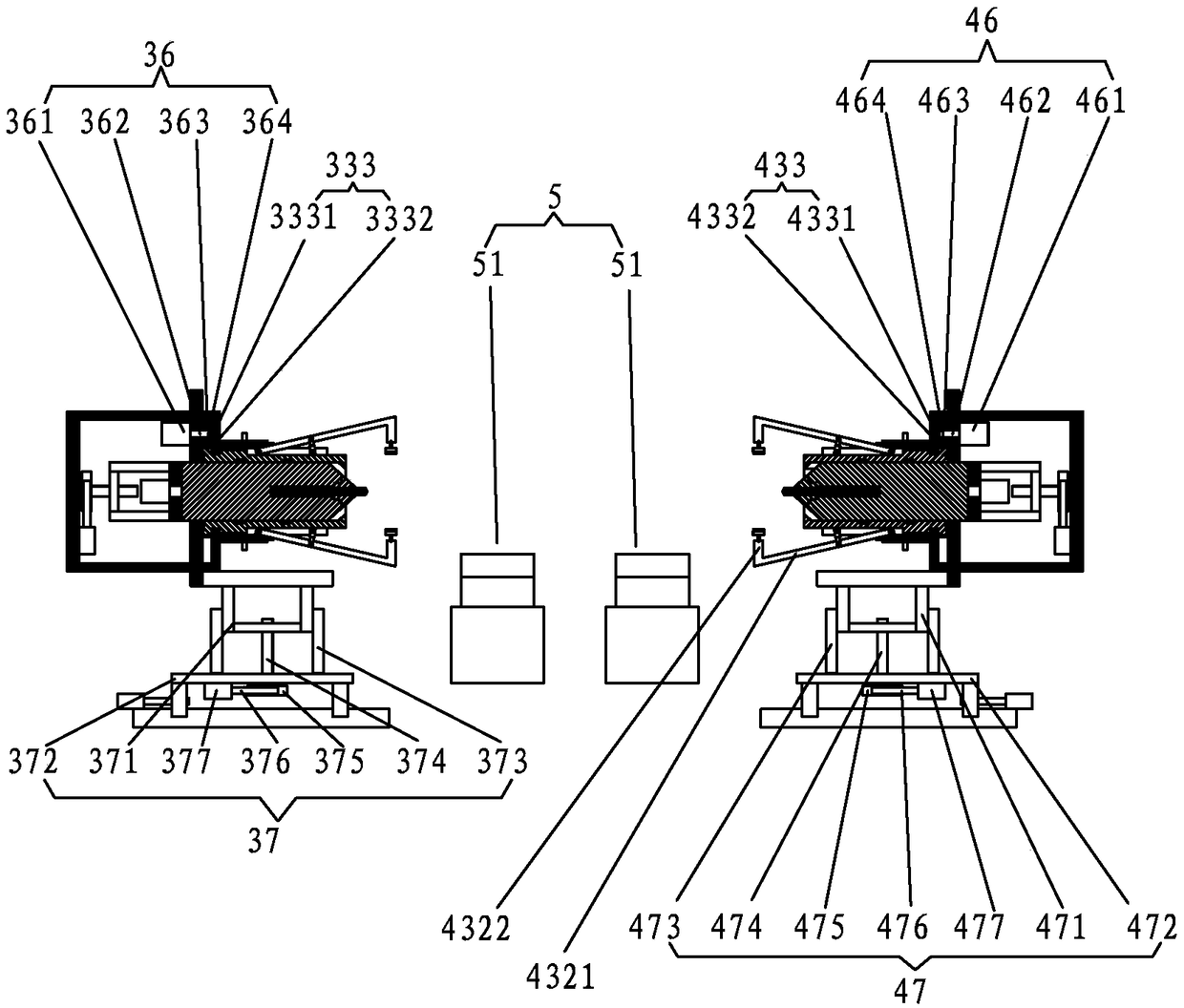

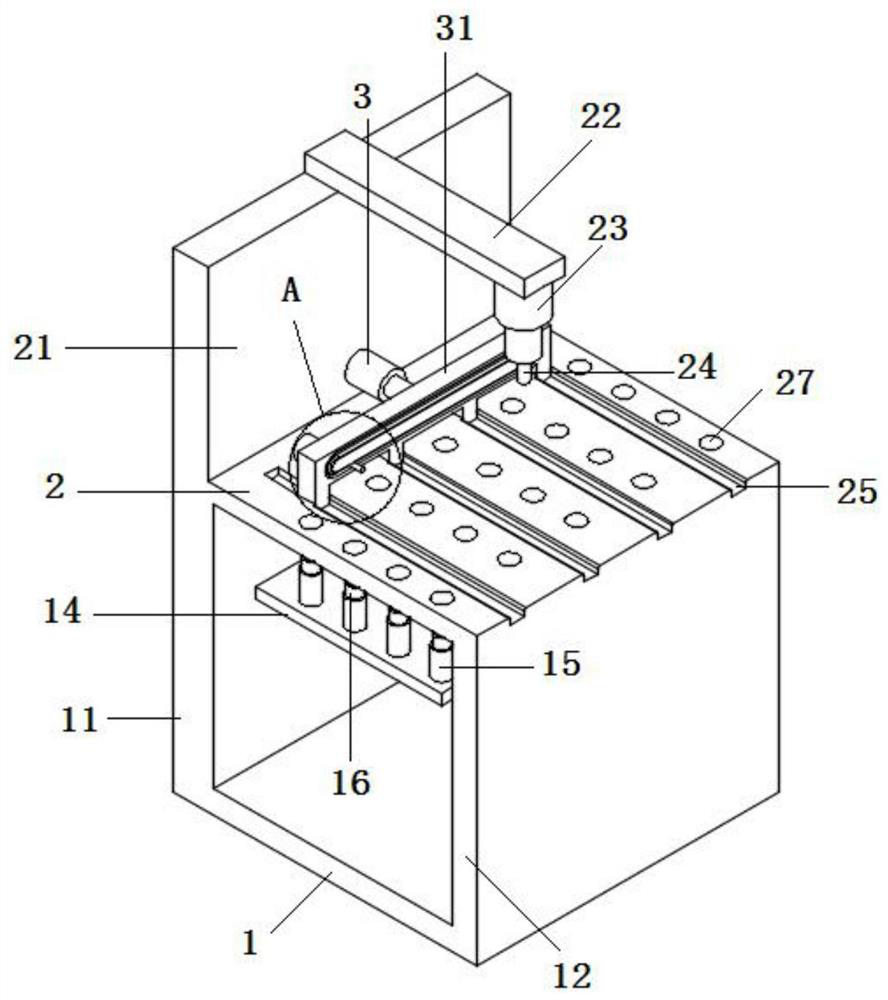

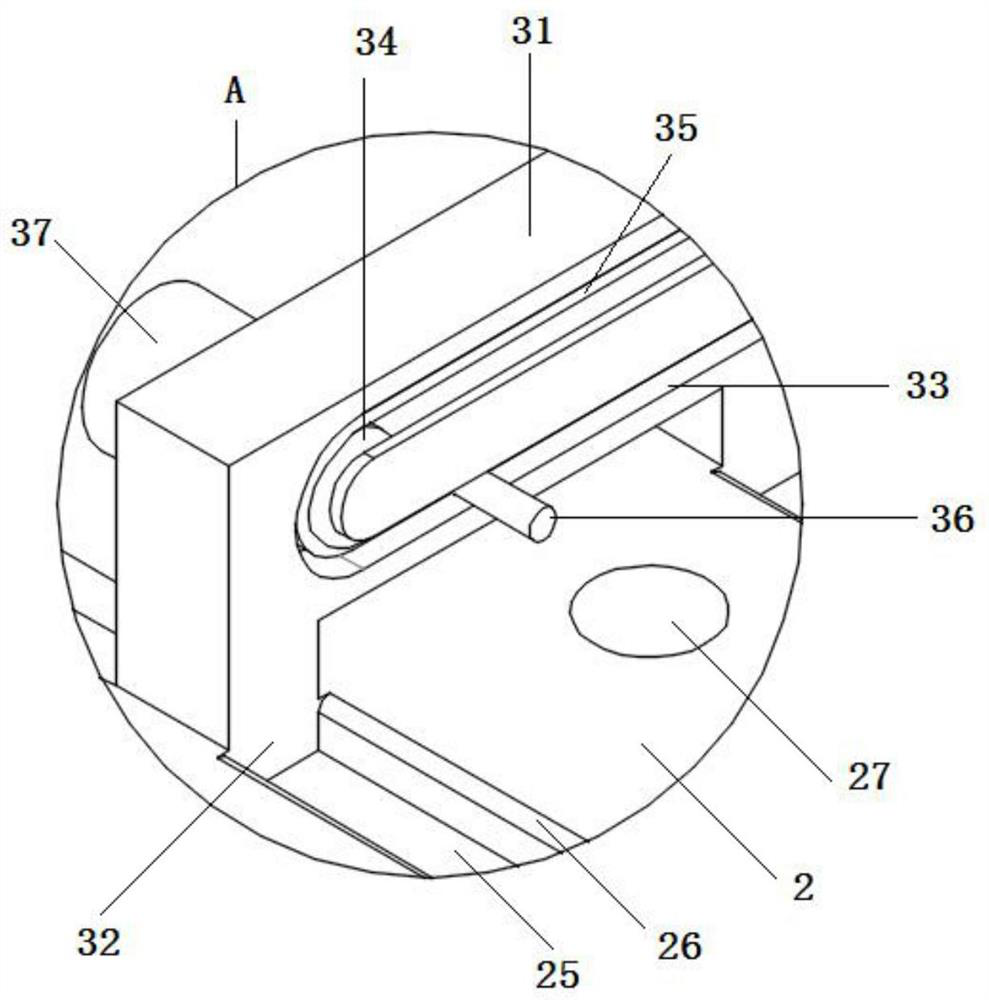

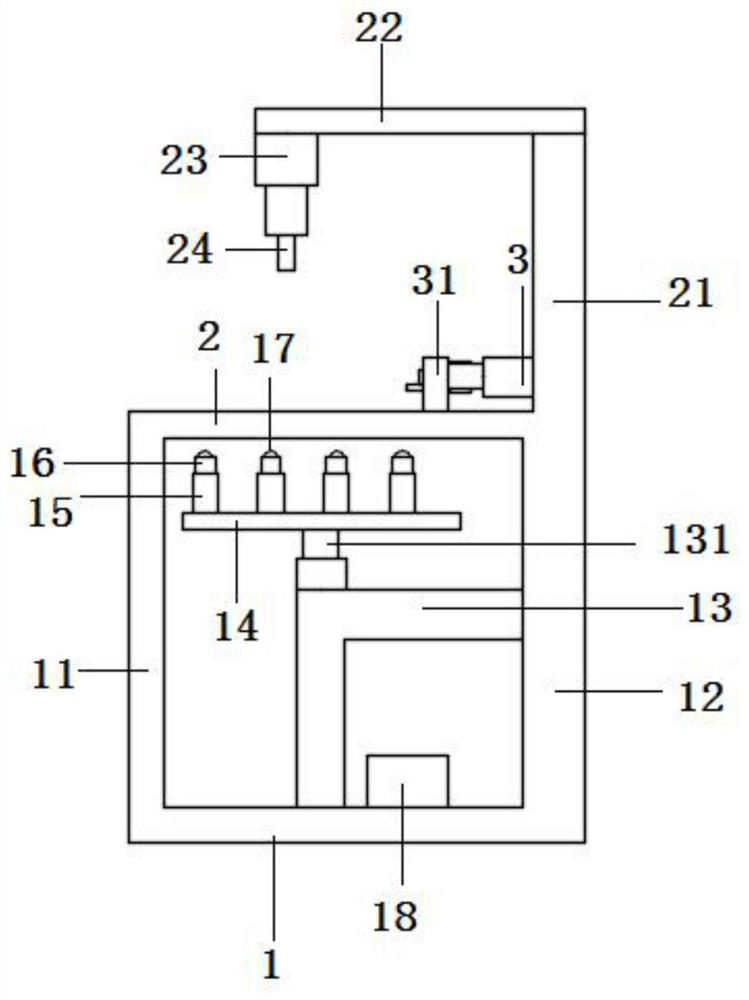

Automatic precision rotary cutting machine

ActiveCN108673686APrecise positioningEasy to holdProfiling/shaping machinesVeneer manufactureMotor driveEngineering

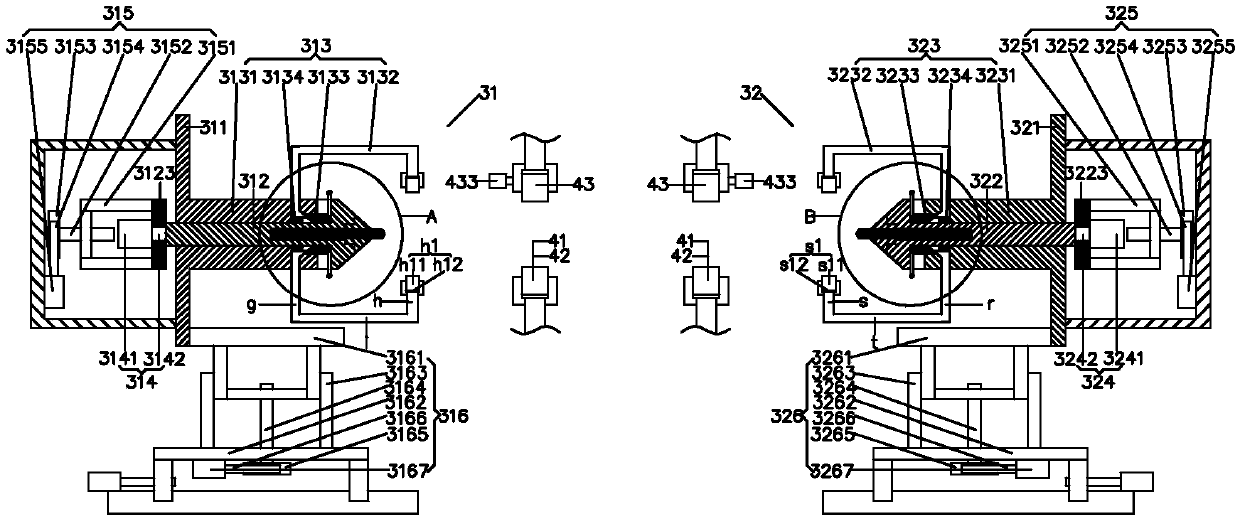

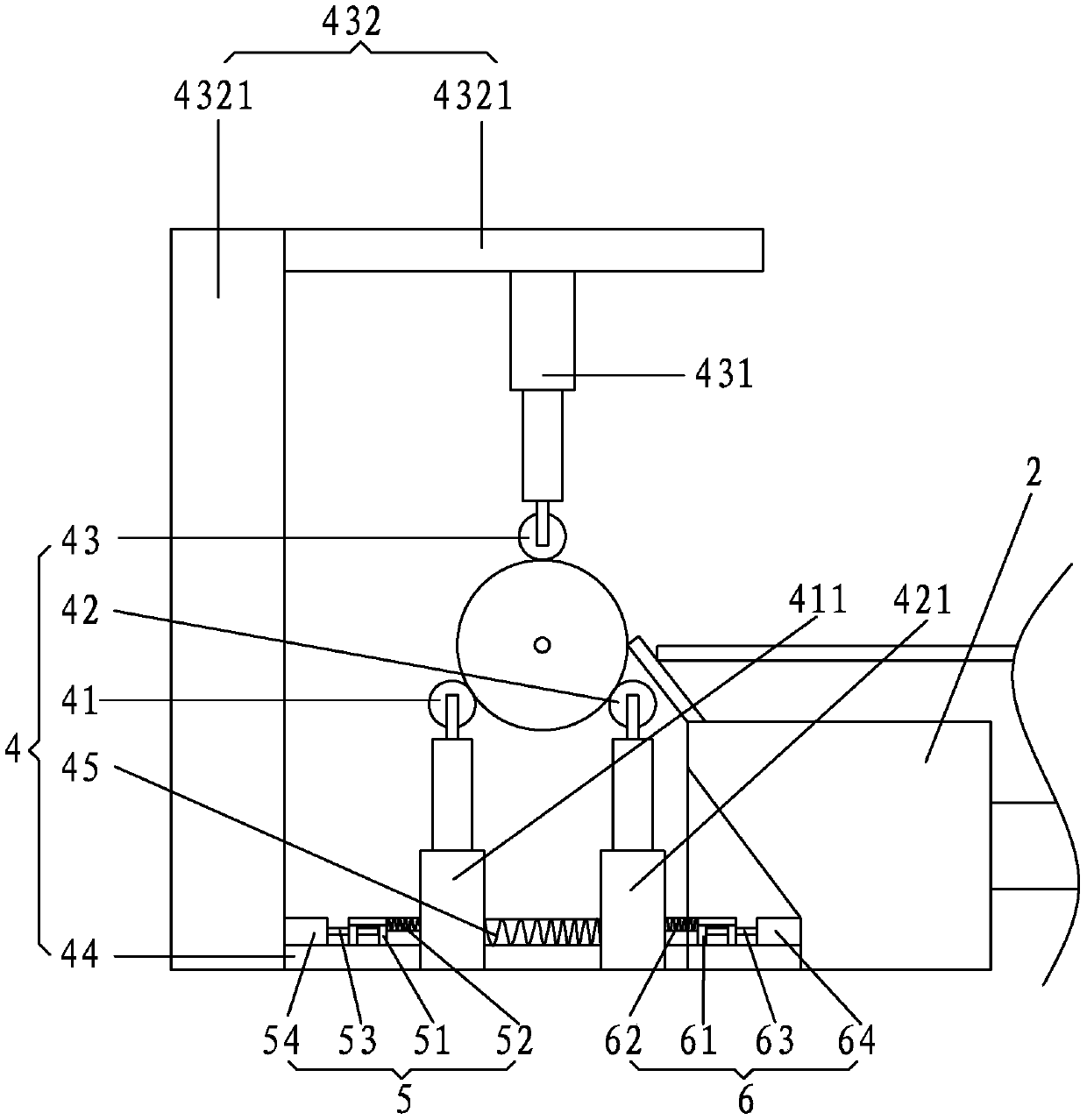

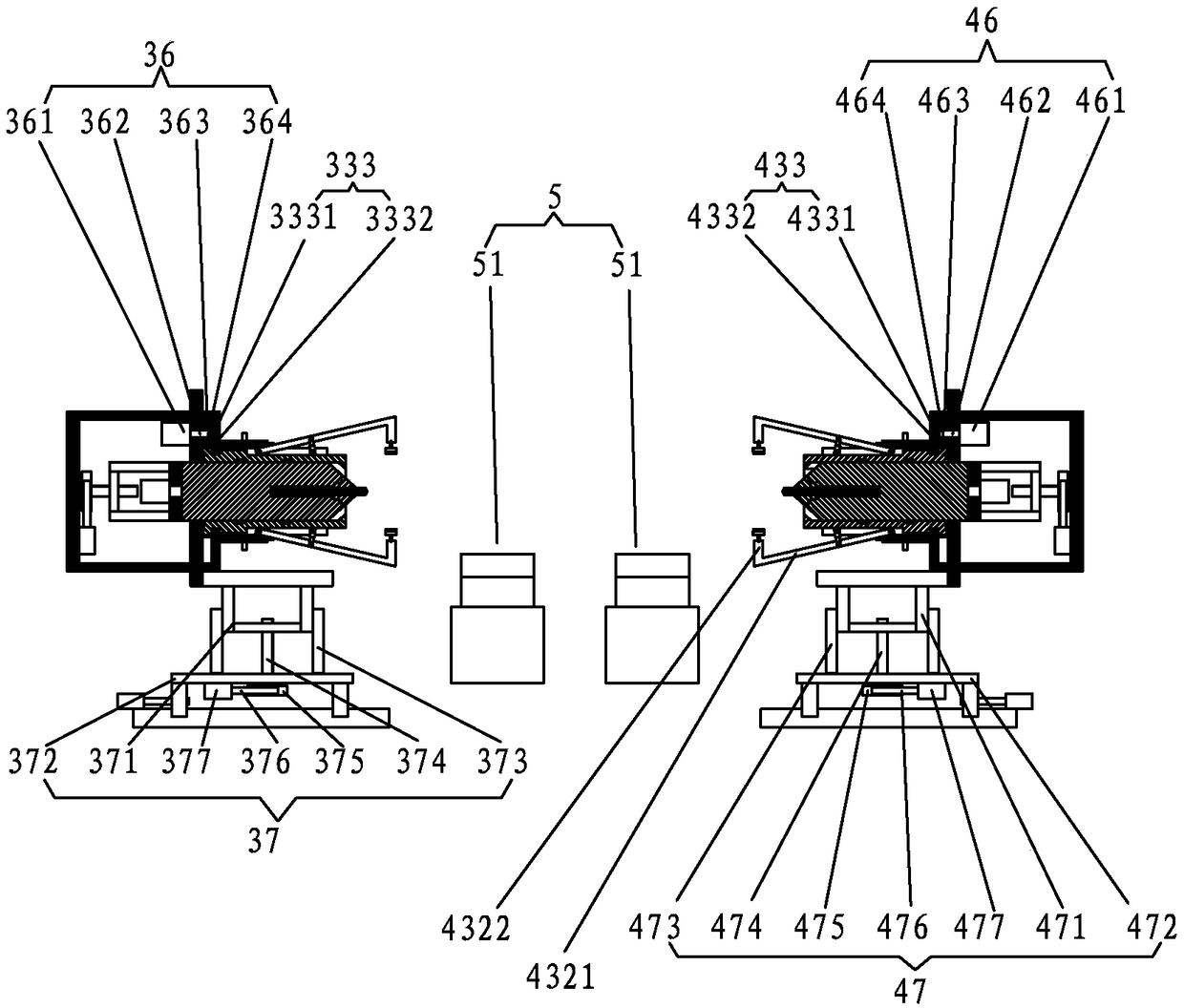

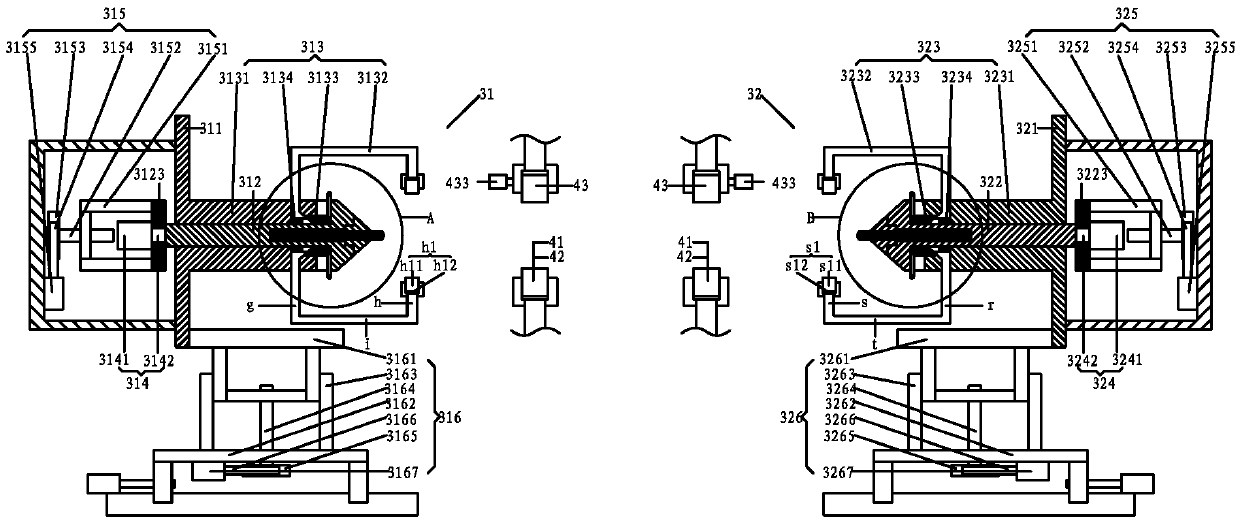

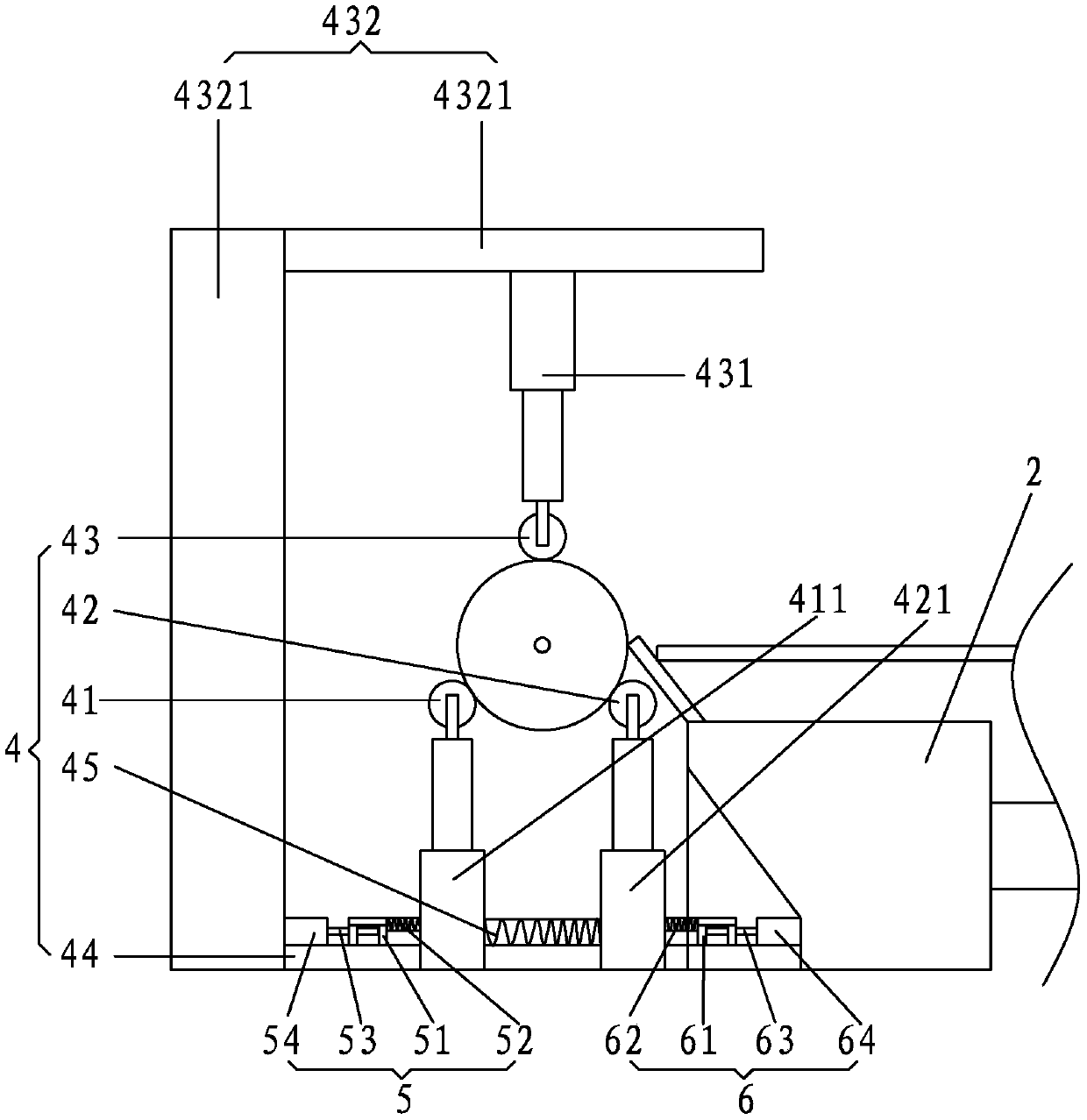

The invention puts forwards an automatic precision rotary cutting machine. Before a rotary cutting device begins to perform rotary cutting, a first lifting driving device slides away from a second clamping part along a first horizontal guiding rail, a first lower telescopic supporting rod and a second lower telescopic supporting rod slide to make contact with a log in an abutting manner, the log is supported to abut against an upper driving wheel single body, a first advancing and retreating motor drives a first rotating shaft to move away from a second clamping part, a first lifting frame moves to the height, corresponding to the circle center of the log, of a first cutter, a worker rotates a first operating handle for adjustment, the first clamping arm clamps the log, a controller controls driving of a first lifting motor, the pressure applied by a first main base plate to the first lifting frame before the log is clamped is equal to the pressure after the log is clamped, the first lifting driving device slides towards the second clamping part along the first horizontal guiding rail, the first rotating shaft moves towards the second clamping part, and the first cutter is automatically aligned to the log.

Owner:漳州市炯辉机械有限公司

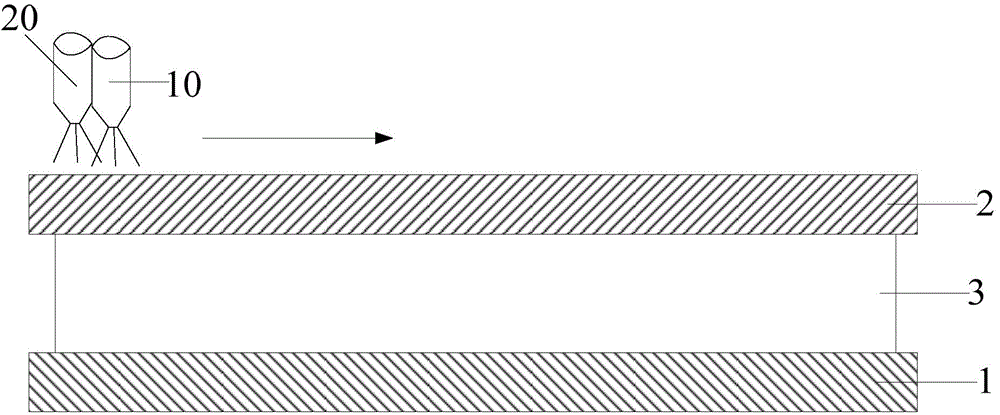

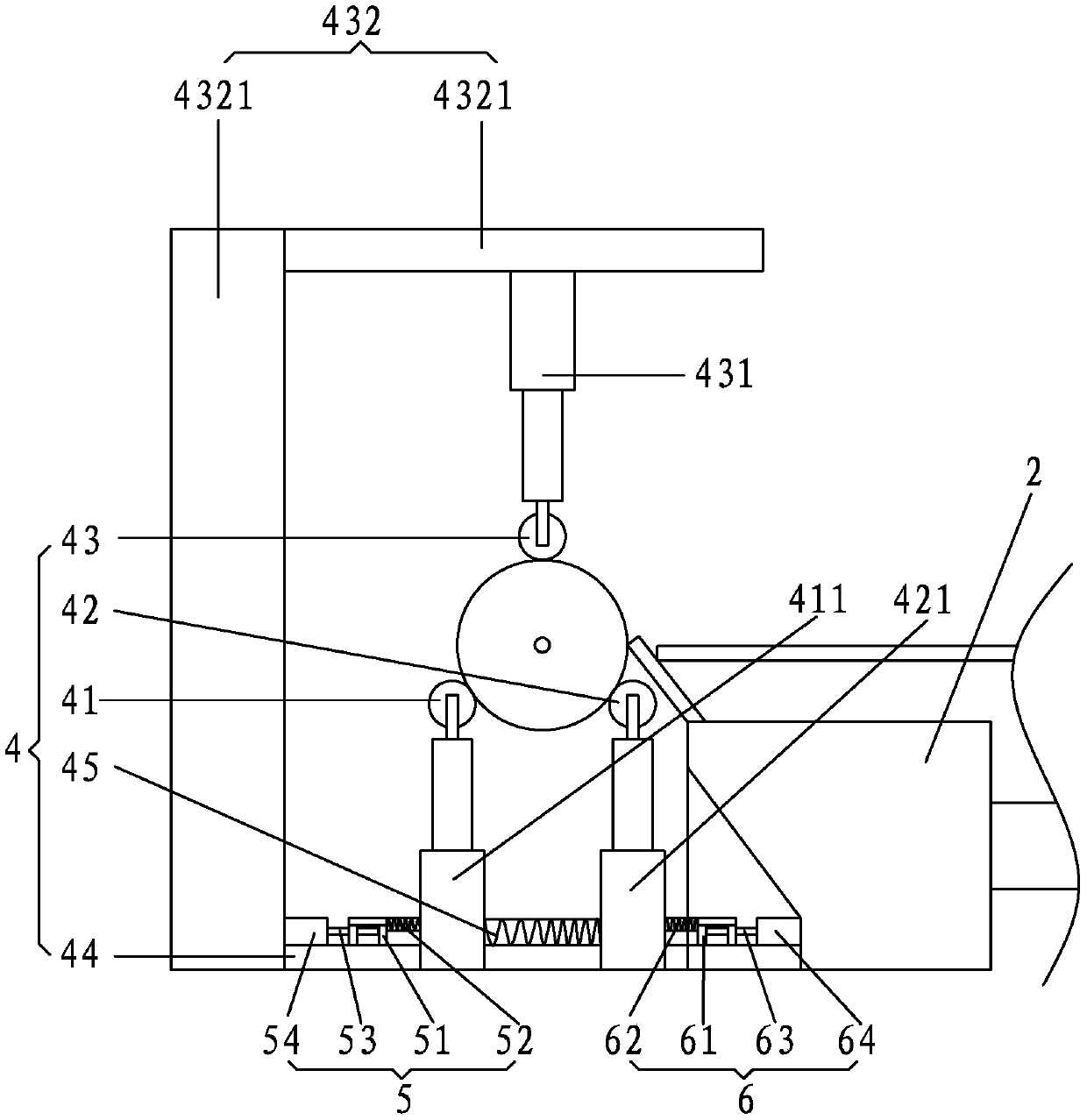

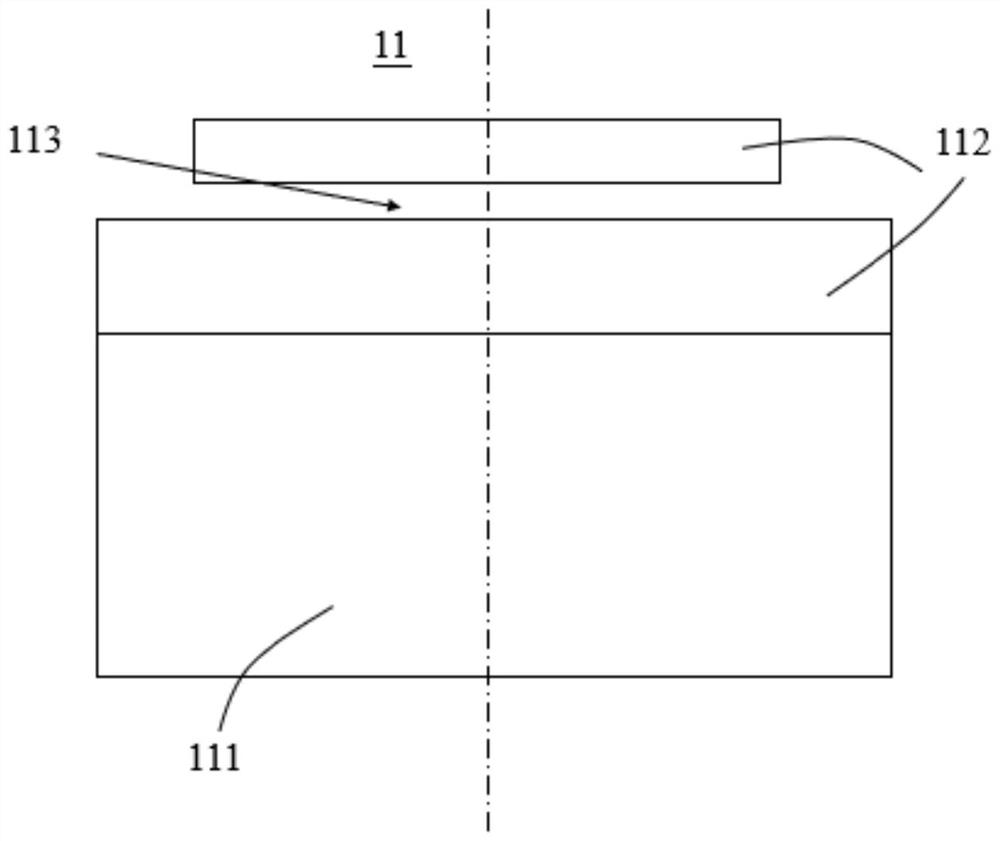

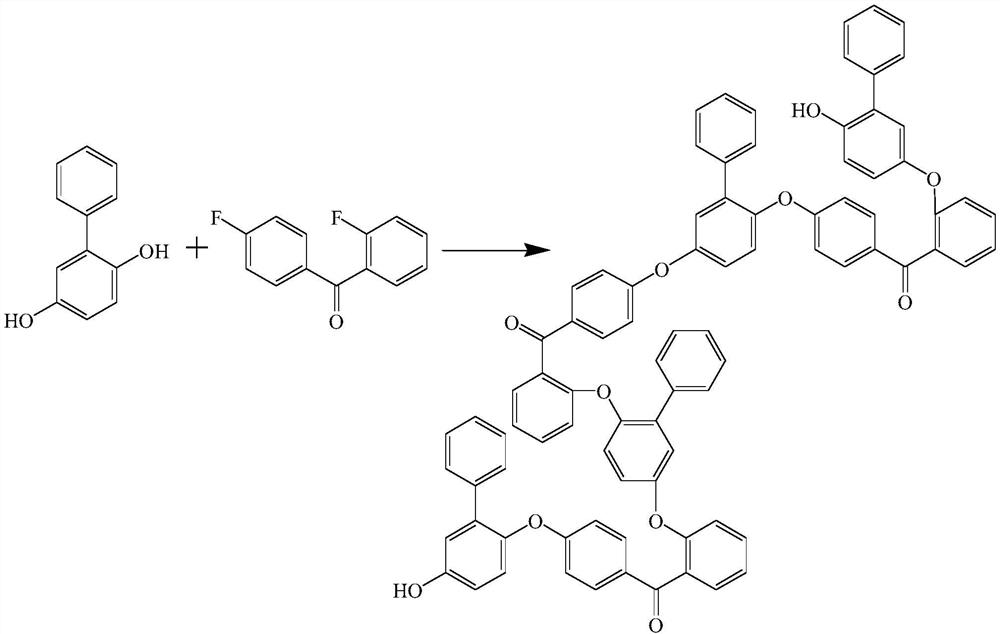

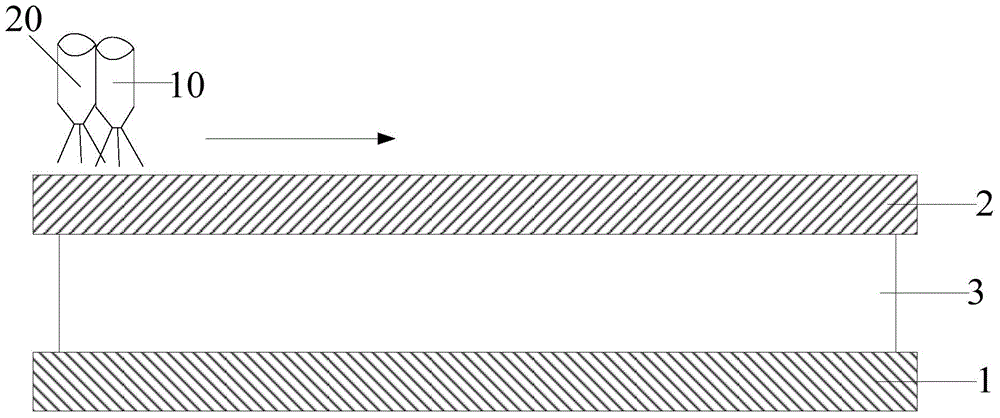

Laser sintering device and sintering method

ActiveCN104466033AReduce stressReduce temperature differenceAdditive manufacturing apparatusSolid-state devicesOptoelectronicsLaser

The invention provides a laser sintering device and sintering method. The laser sintering device comprises a first laser head used for outputting a laser of first power, a second laser head used for outputting a laser of second power and a drive device used for driving the first drive head and the second drive head to move, and the first laser head and the second laser head are made to heat the same area of a material to be sintered. When the two laser heads are used for heating the to-be-sintered material arranged on a to-be-sintered device, the two laser heads are made to heat a certain to-be-heated area of the to-be-sintered material, therefore, the to-be-sintered material is preheated before laser sintering, or annealing treatment is carried out on the to-be-sintered material after laser sintering, therefore, the difference of the temperature obtained before laser sintering and the temperature in the laser sintering process is reduced, or the reducing speed of the temperature obtained after laser sintering is reduced, so that the stress of a substrate of the to-be-sintered material is reduced, and the situation that cracks or even damage is caused by shrinkage stress is avoided.

Owner:BOE TECH GRP CO LTD +1

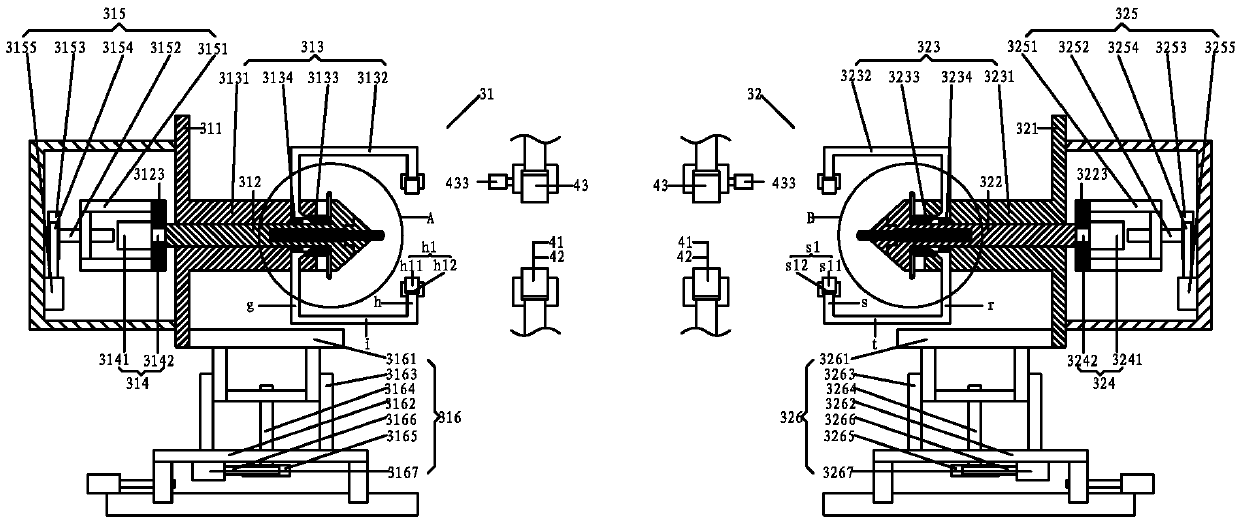

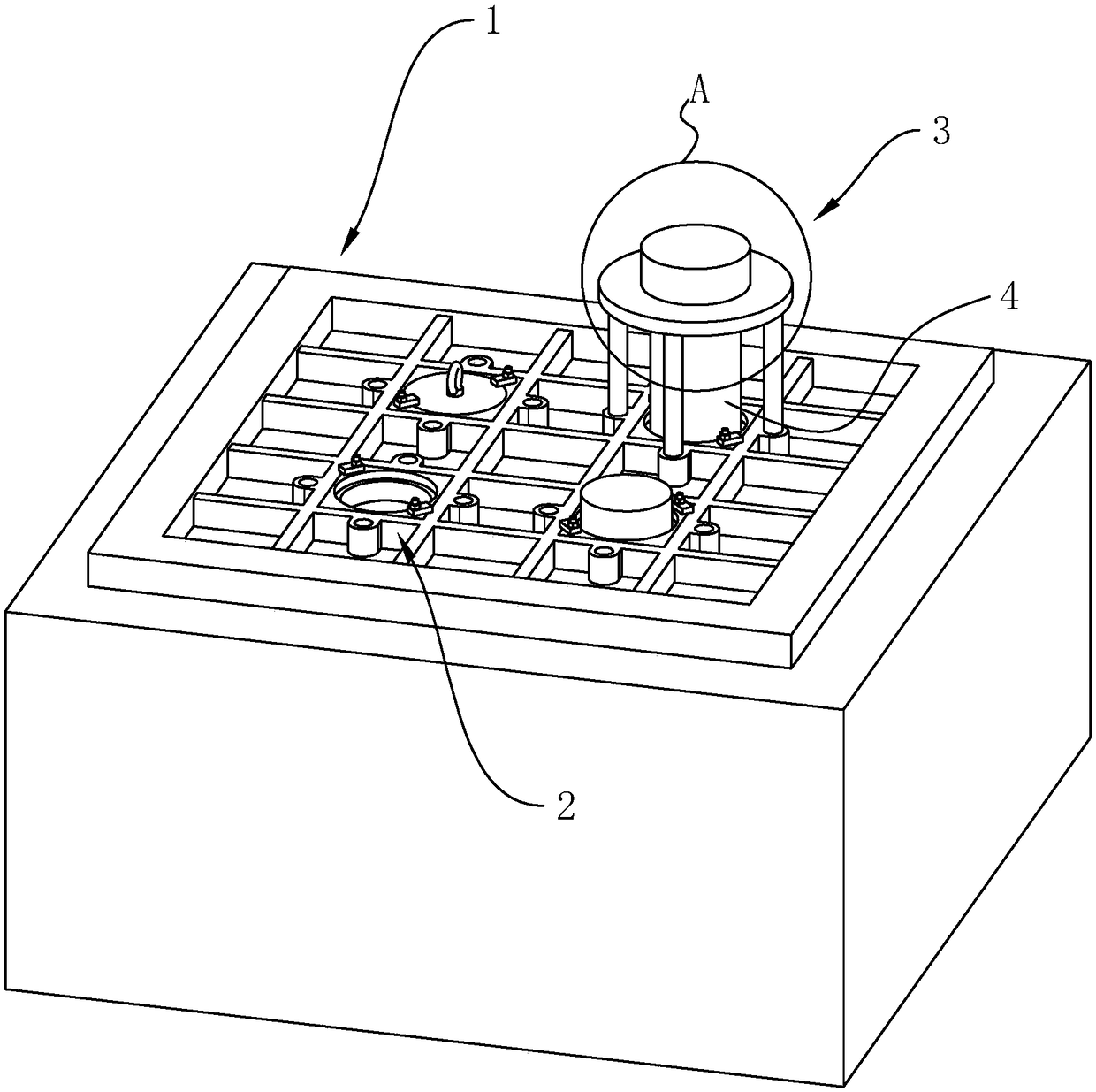

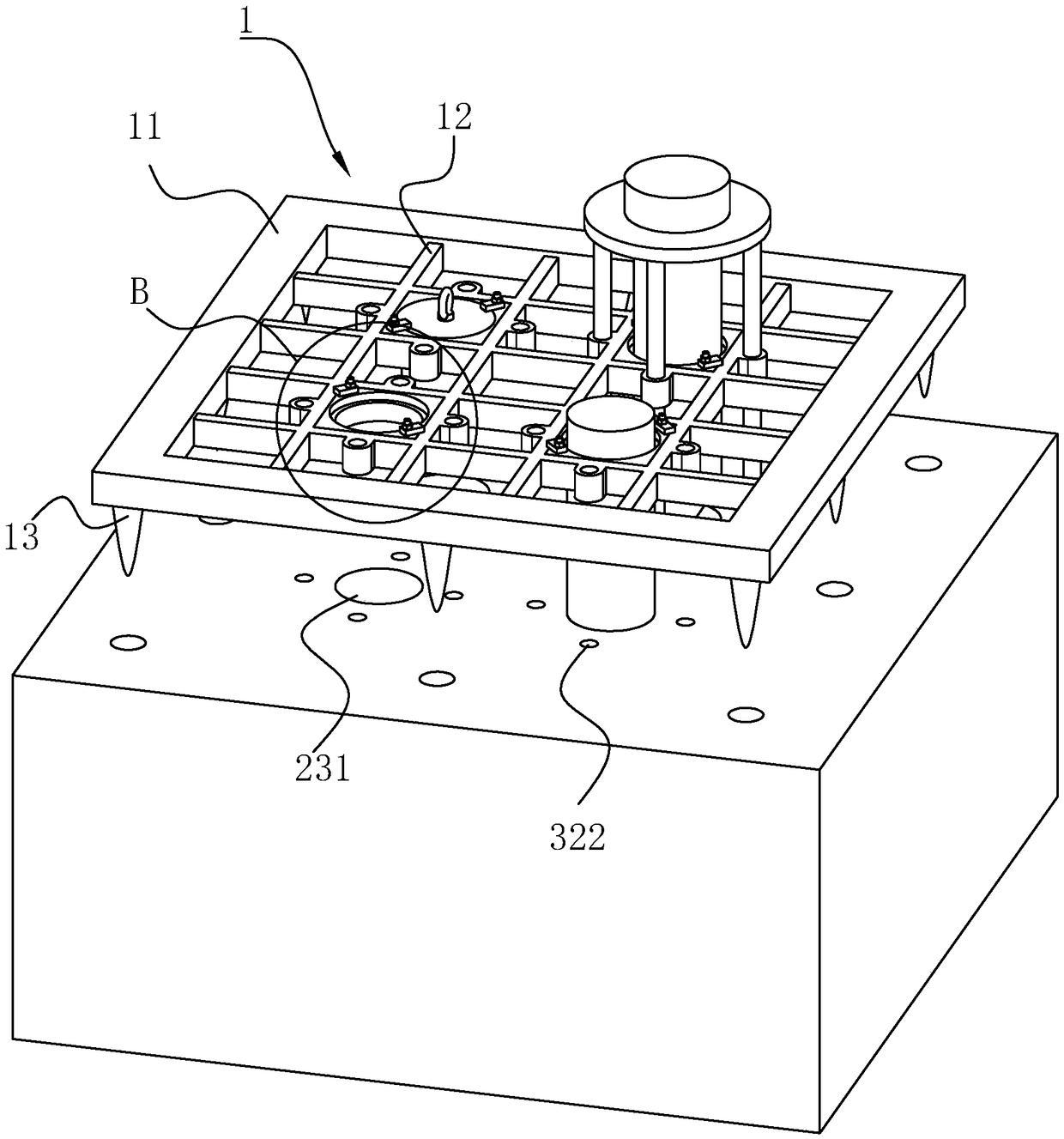

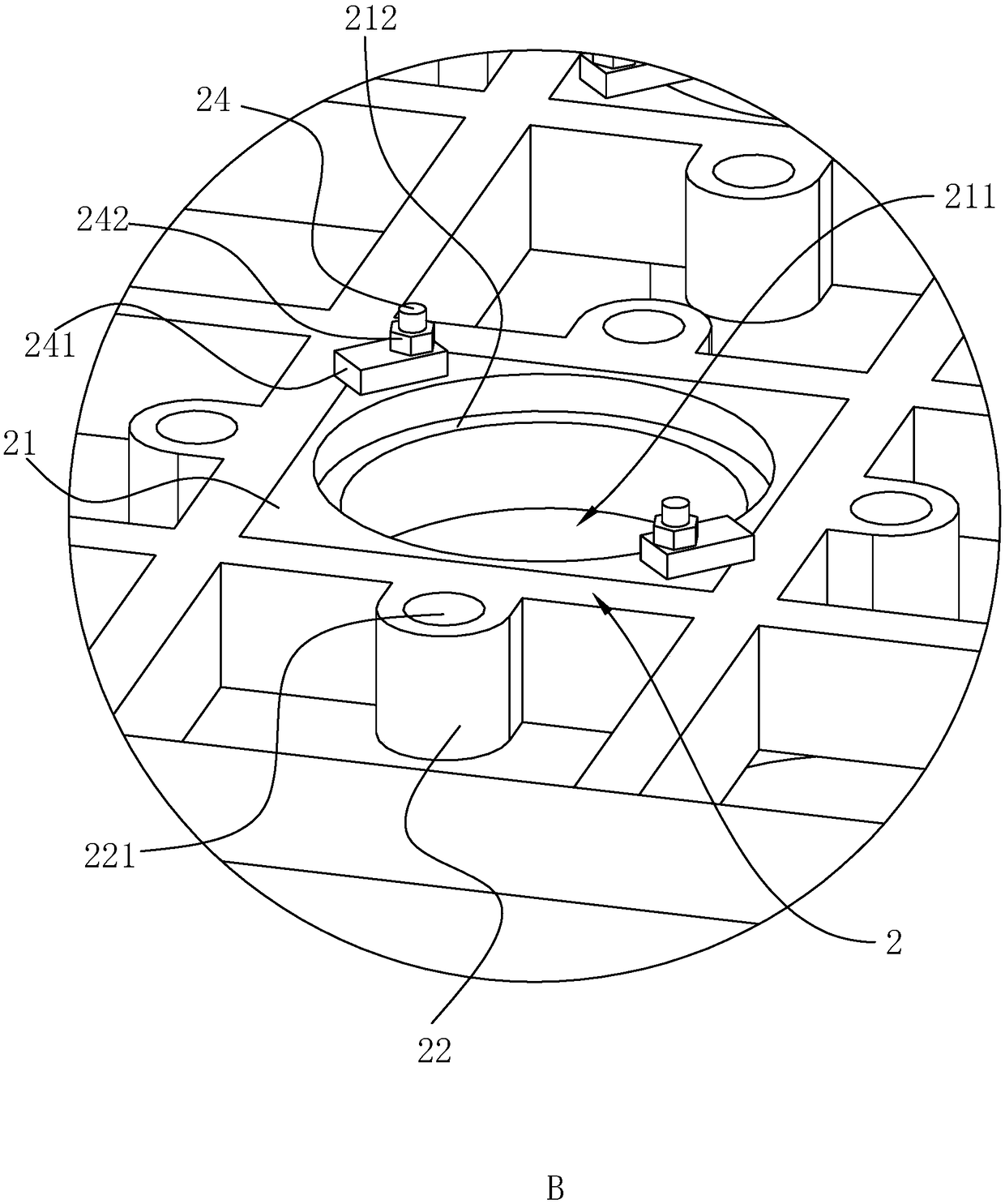

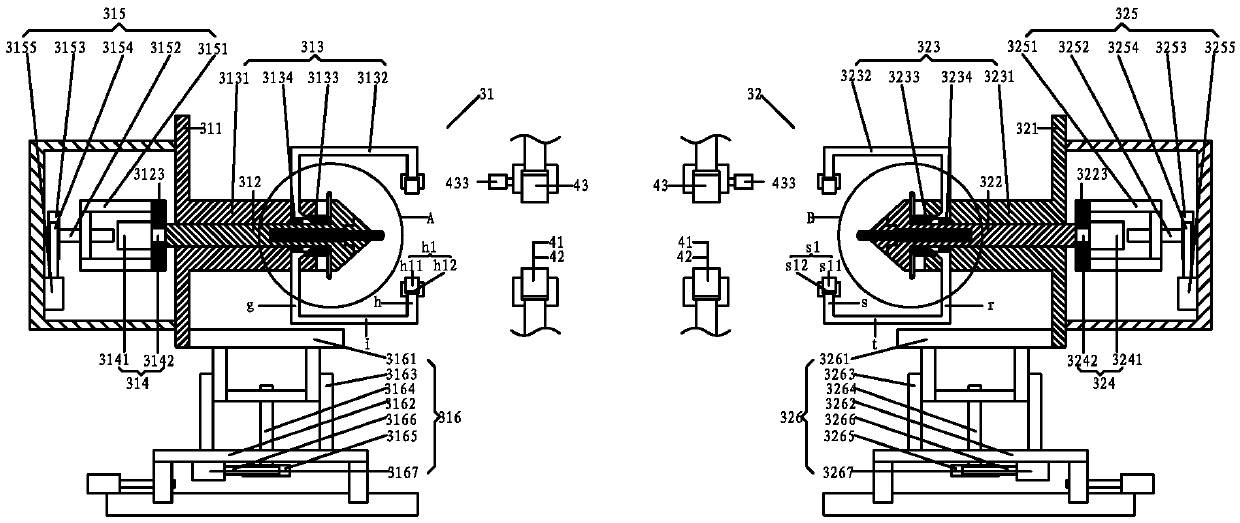

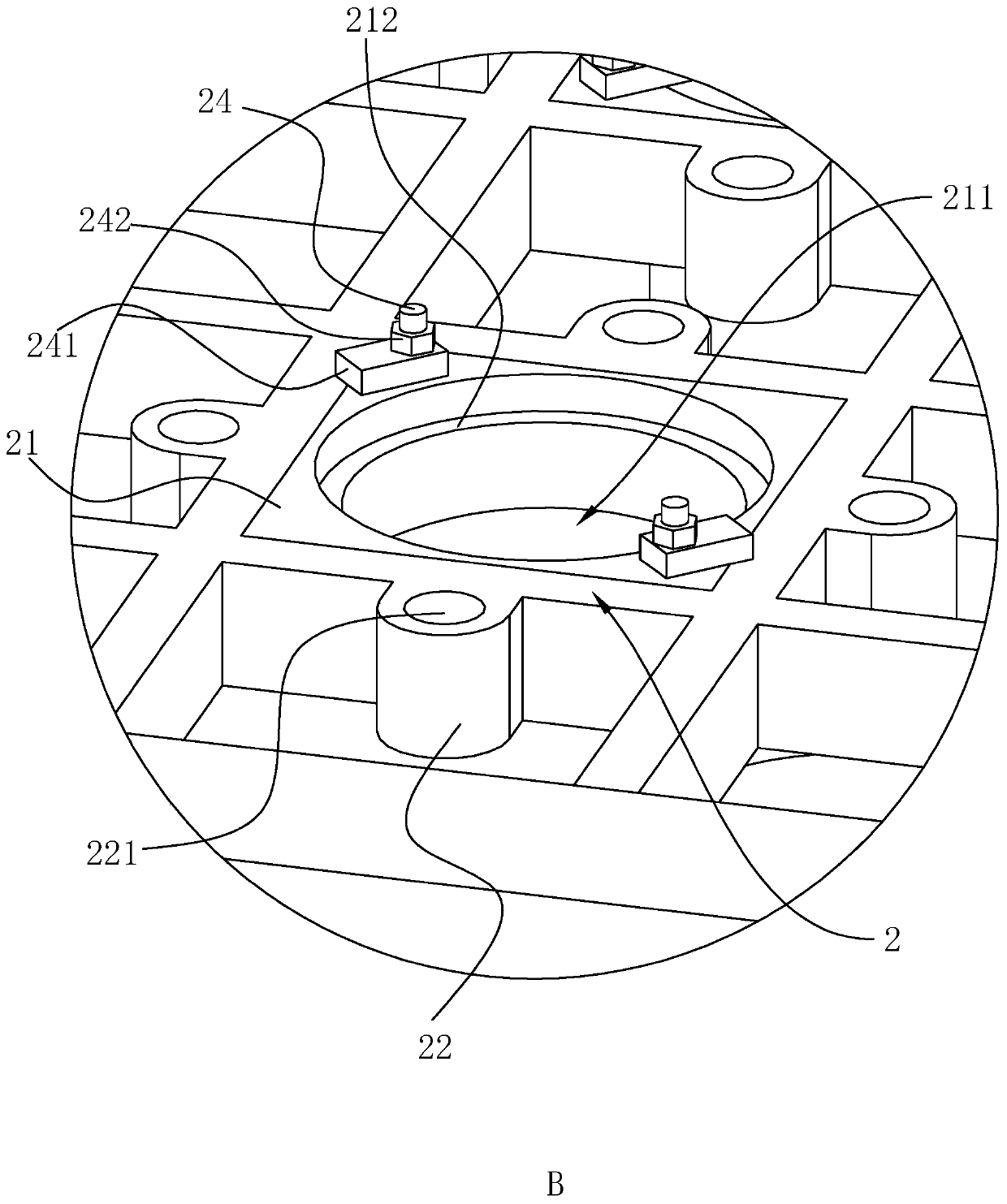

Efficient and stable rotary cutting machine

ActiveCN108673687APrecise positioningAvoid scratchesProfiling/shaping machinesVeneer manufactureDrive wheelEngineering

The invention discloses an efficient and stable rotary cutting machine. Before the rotary cutting device begins rotary-cut operation, a first lifting driving device slides along a first horizontal guide rail in a direction away from a second clamping part. A first lower telescopic support rod and a second lower telescopic support rod slide to abut against a round wood, thereby supporting the roundwood to abut against an upper driving wheel body. A first rotating shaft is moved in the direction away from the second clamping part by driving of a first advancing and retracting motor.A first lifting frame is moved to the height of a first cutting knife corresponding to the circle center of the round wood. A worker rotates a first operation handle to perform adjustment, so that a first clamping arm clamps the round wood. A controller controls the driving of a first lifting motor, ensures that the pressure of a first main substrate on the first lifting frame before clamping the round wood is equal to the pressure after clamping, which makes the first lifting driving device slides along the first horizontal guide rail towards the direction close to the second clamping part, and makes thefirst rotating shaft moves towards the direction close to the second clamping part, so that the first cutting knife is automatically aligned with the round wood.

Owner:漳州市炯辉机械有限公司

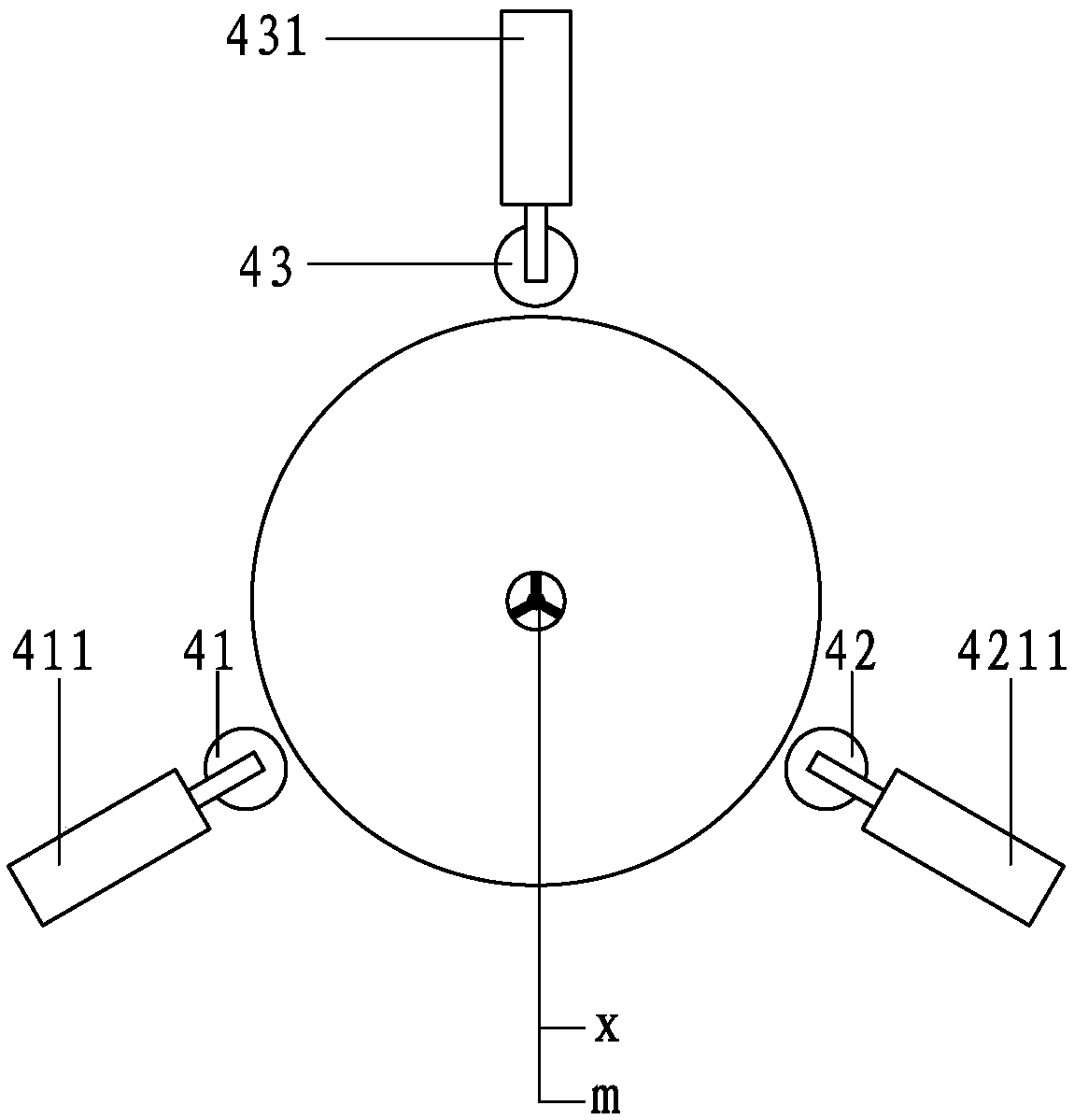

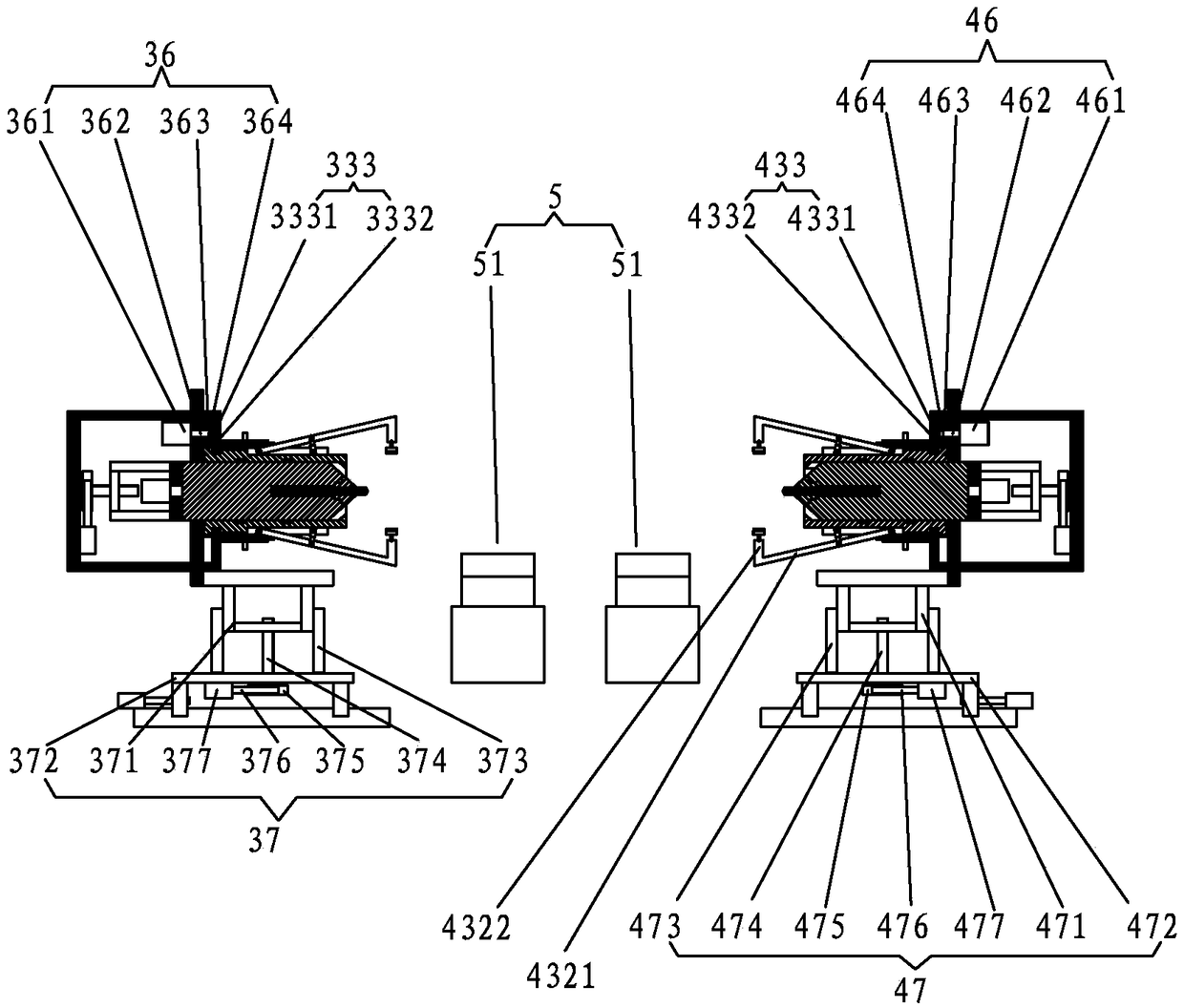

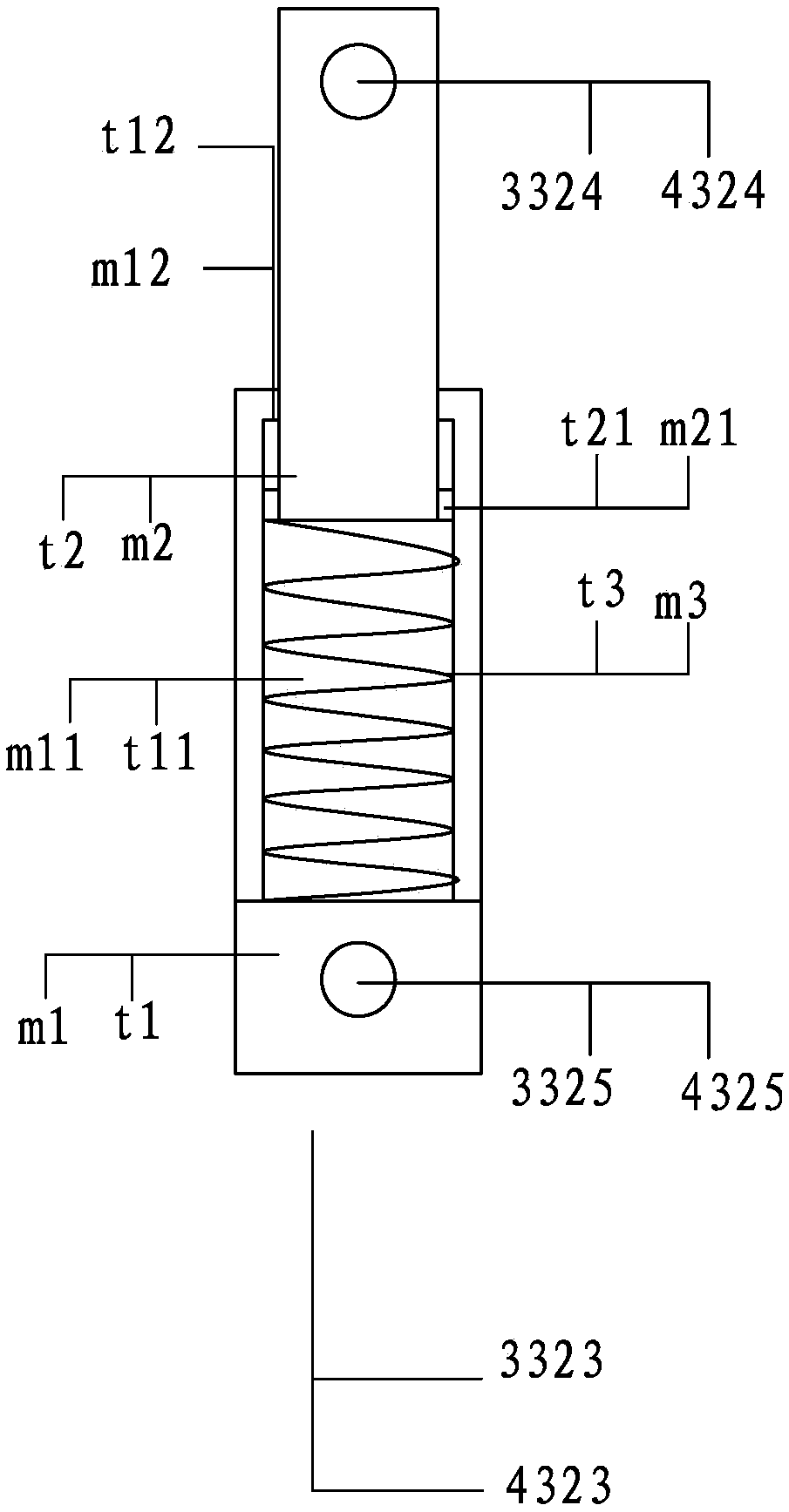

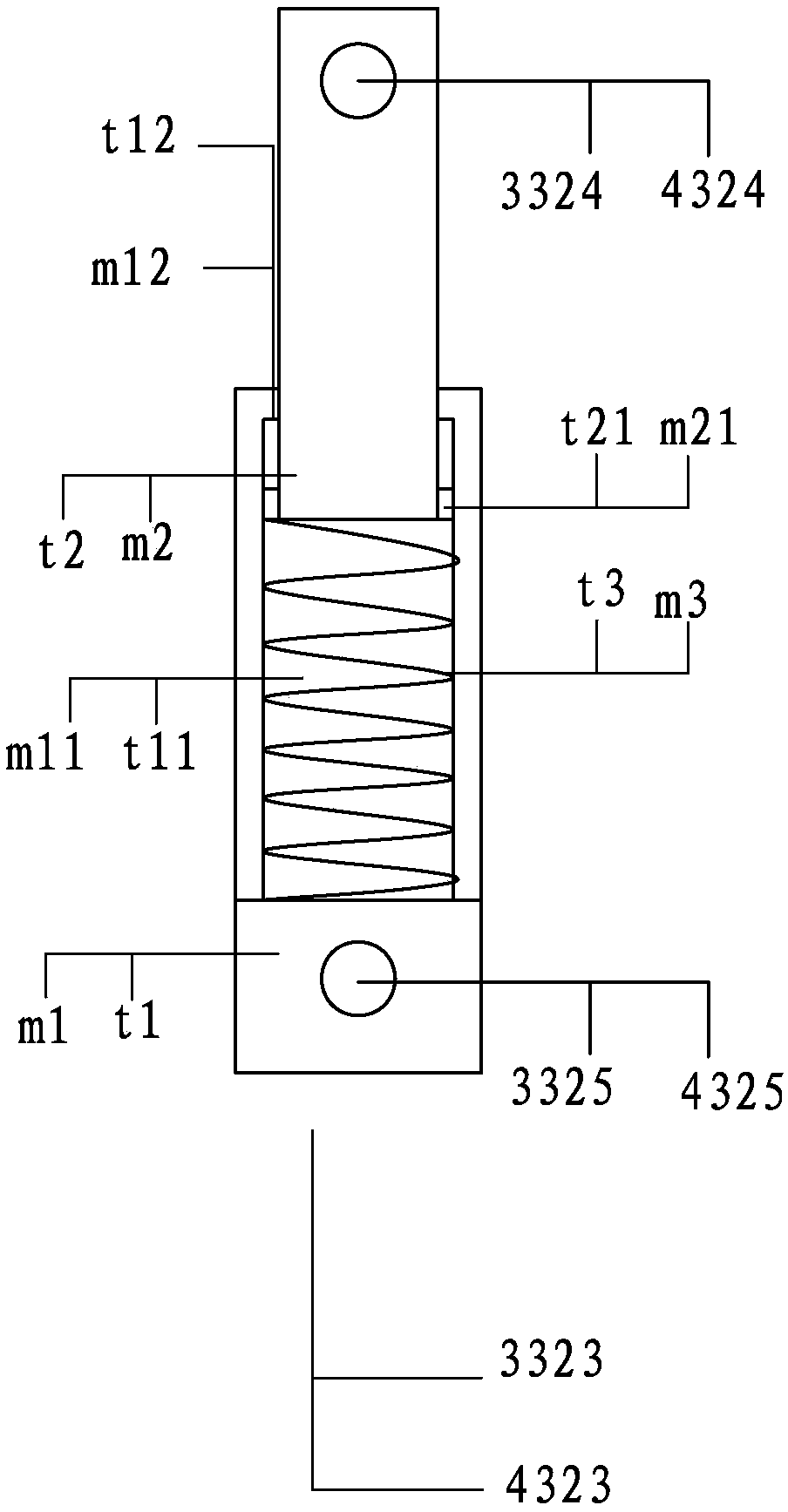

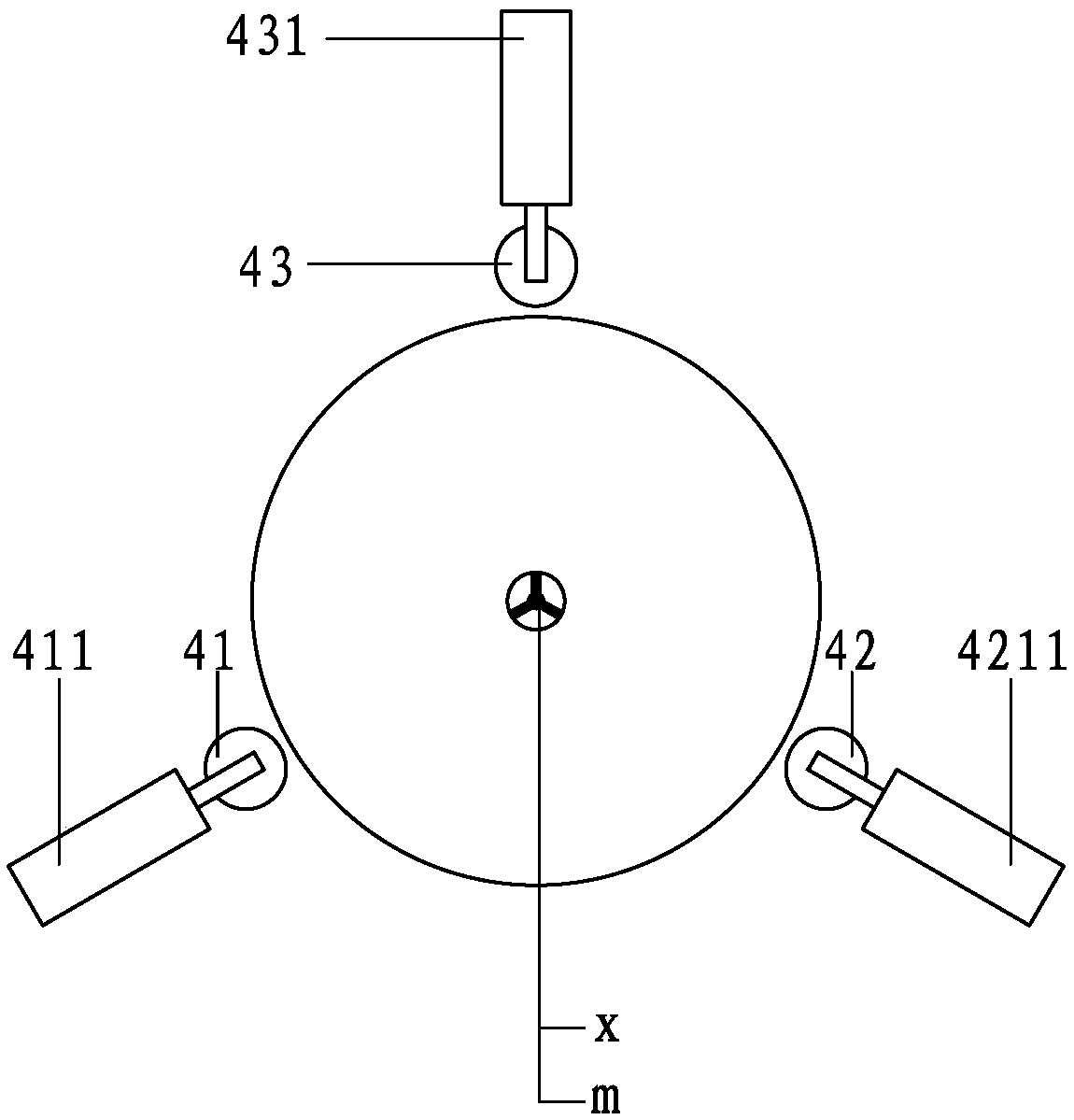

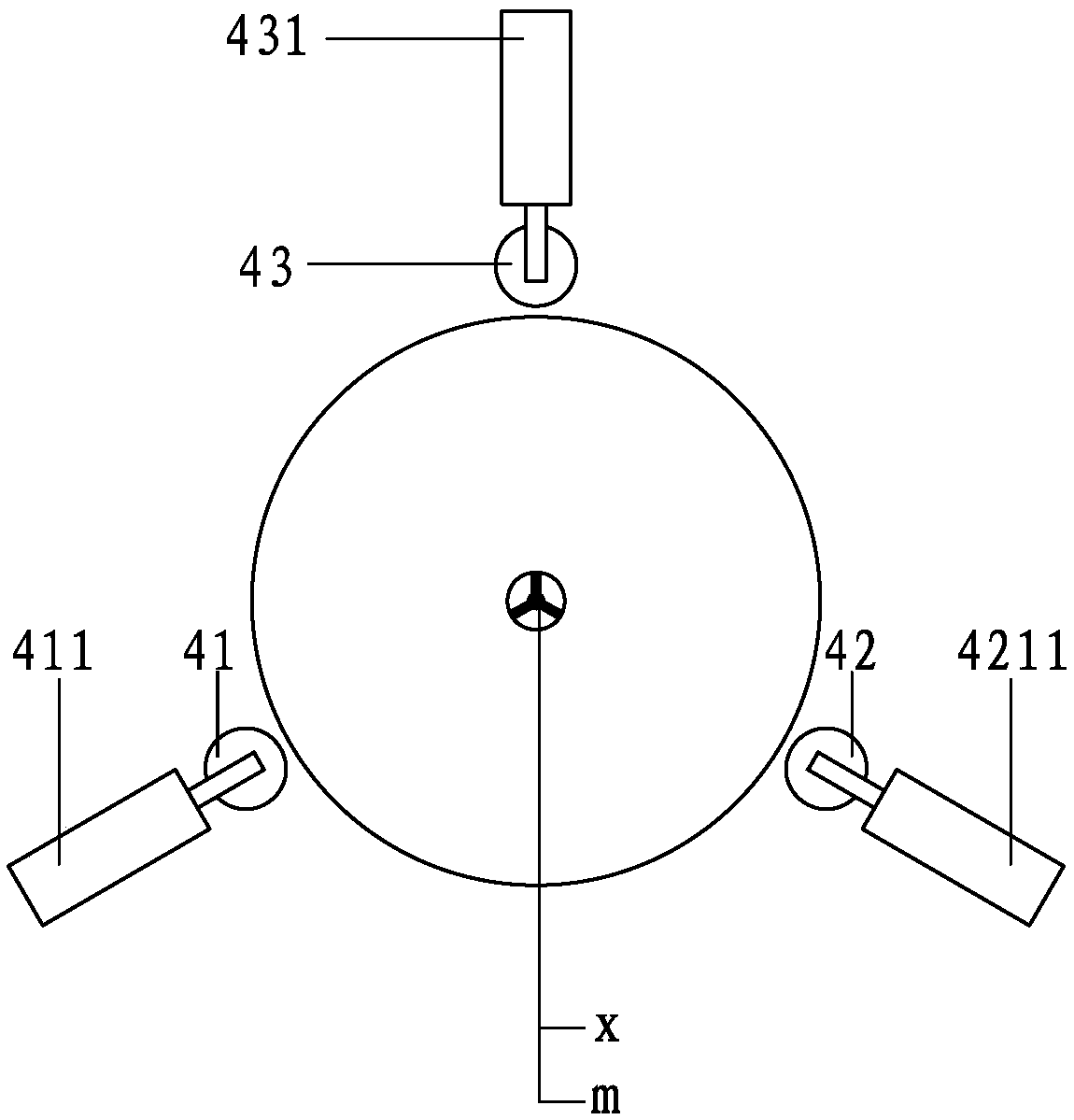

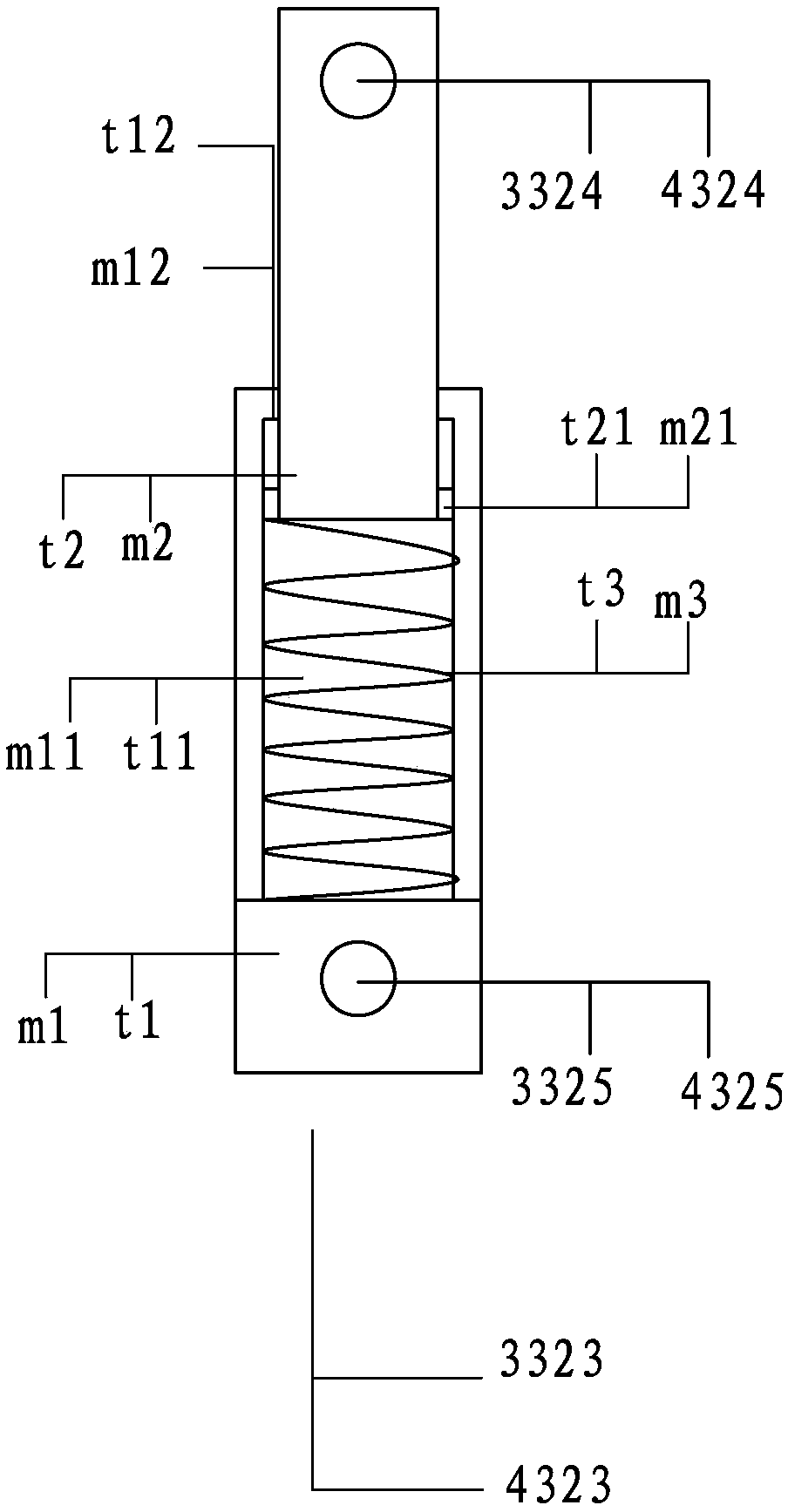

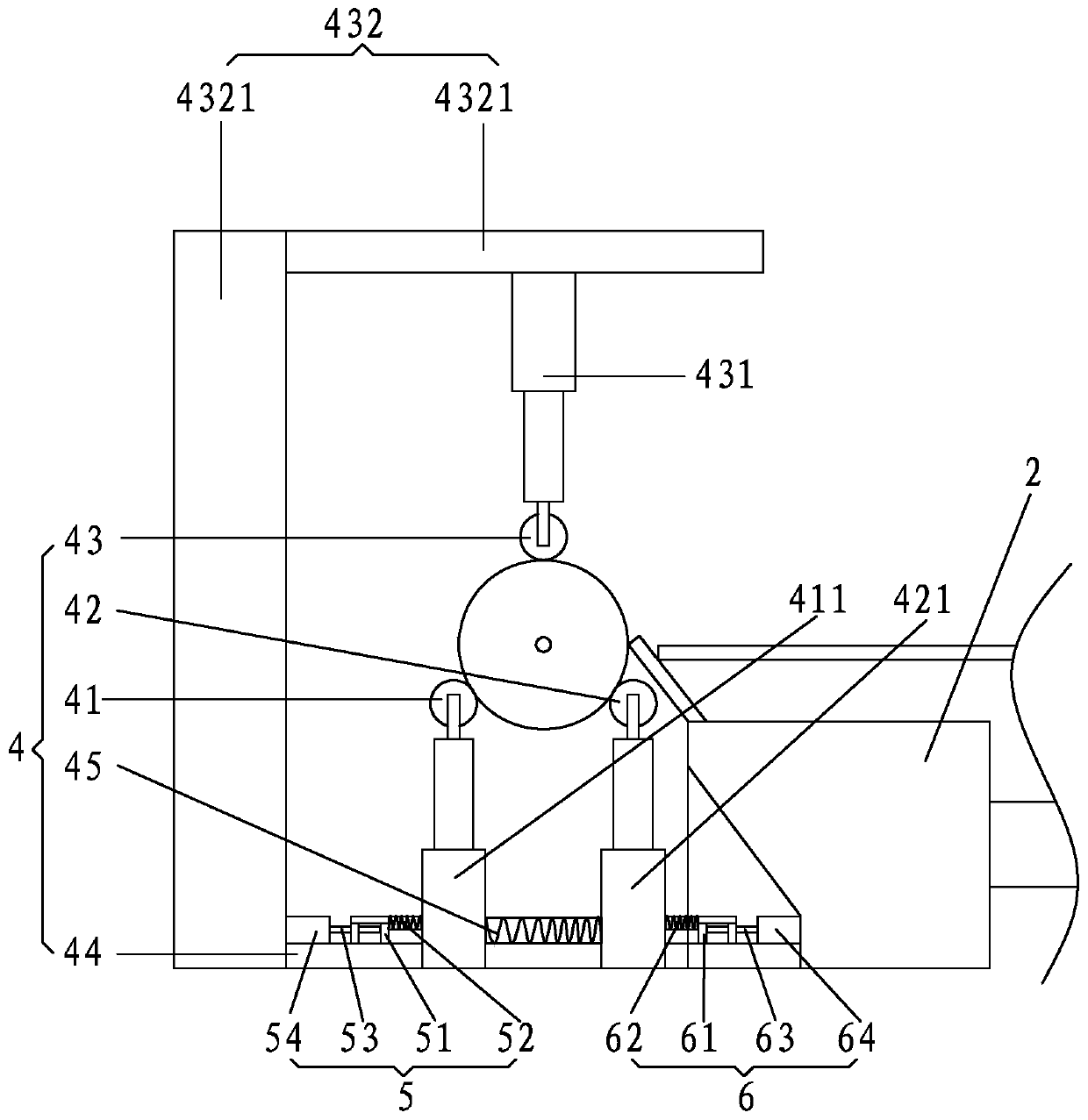

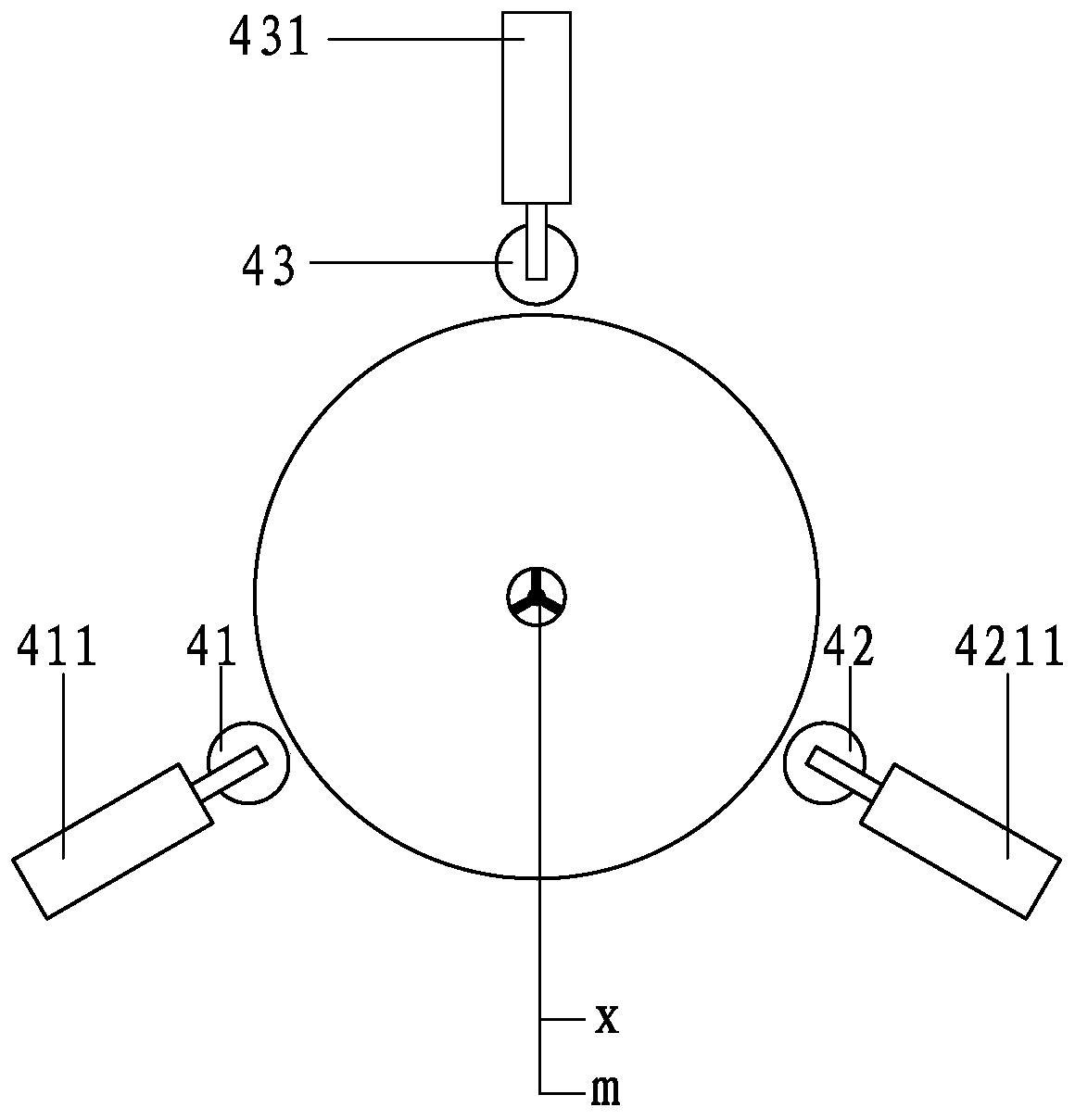

Efficient self-centering rotary cutter

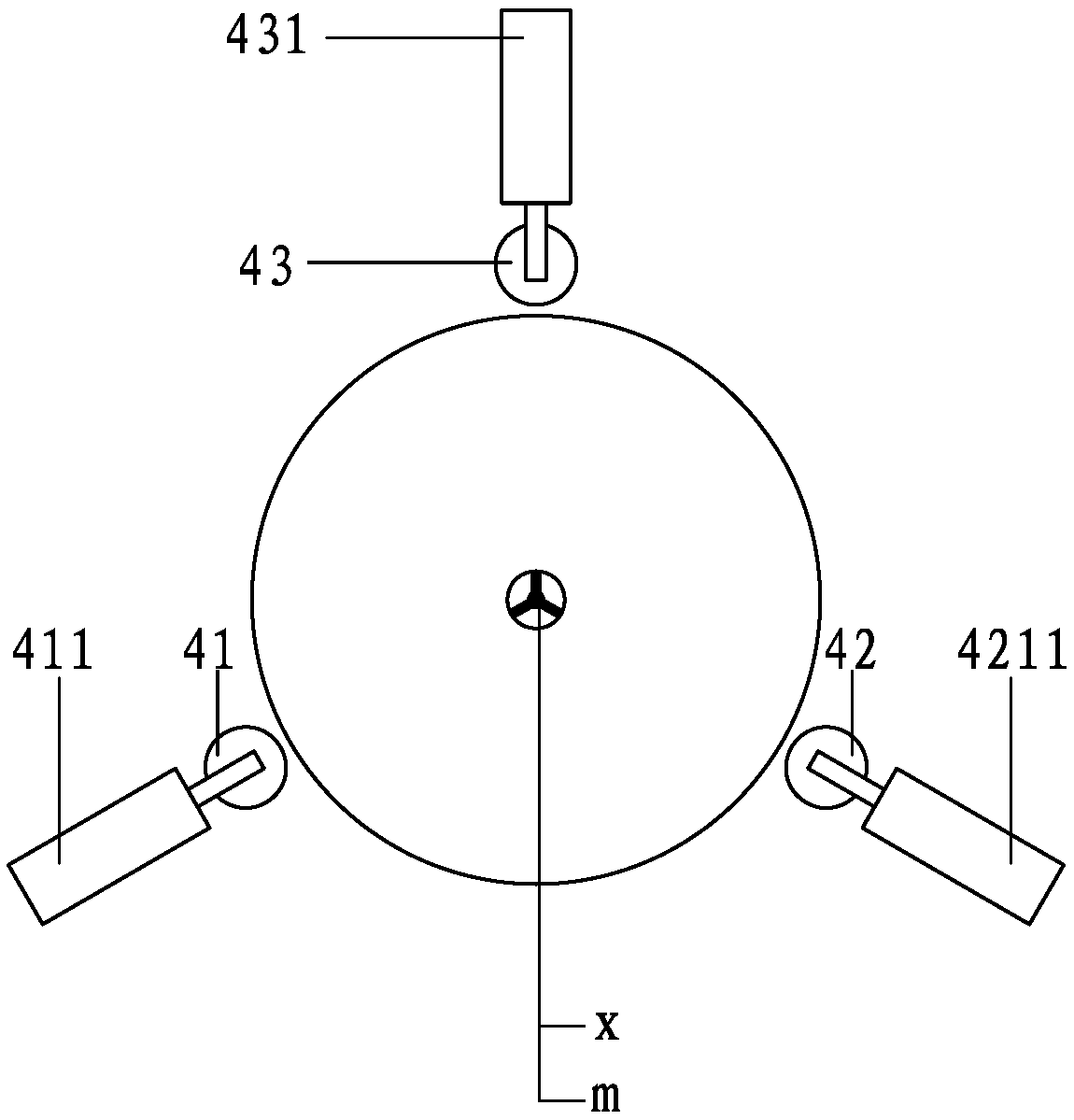

The invention discloses an efficient self-centering rotary cutter. In the rotary-cut process, a first lifting drive device drives a first lifting frame to lift and lower along a first guide frame until the center of a positioning cutting knife is roughly at the same height as the center of a log, a user operates a first operating handle to push a first sleeve body to move along a thread towards the log, the first sleeve body has inward pressure on a first positioning arm through a first top abutting sleeve, the first positioning arm performs clamping through a first top abutting gripper, and top abutting grippers of three positioning arms can perform all-dimensional clamping on the log. A first advance and retreat motor drives a first advance and retreat worm wheel to rotate through a first advance and retreat worm, the first advance and retreat worm wheel drives a first shaft body to slide towards the log through a first advance and retreat screw, a first blade is in contact with thelog in a top abutting mode and the log is rotated to cut a groove corresponding to a first conical head, a first end cover is automatically in contact with the groove formed by rotary cutting in a topabutting mode, and the self-centering effect is realized.

Owner:漳州市炯辉机械有限公司

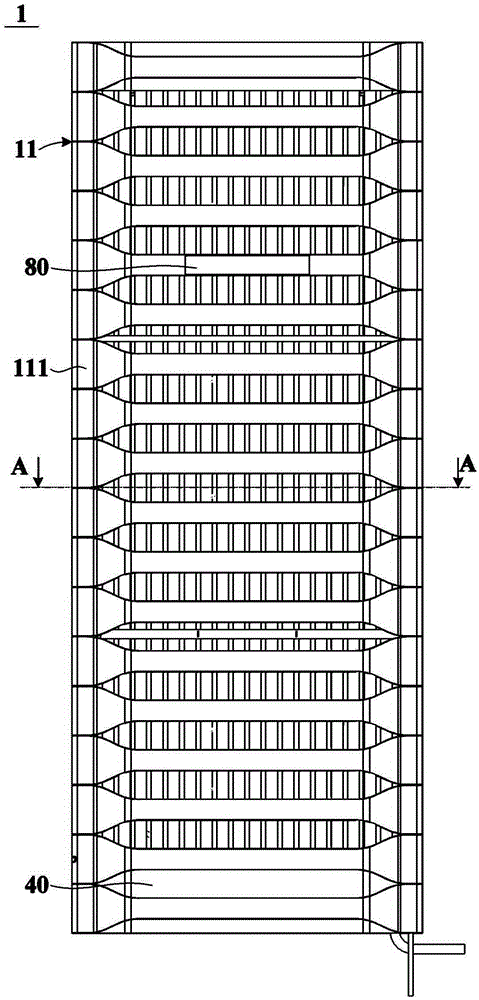

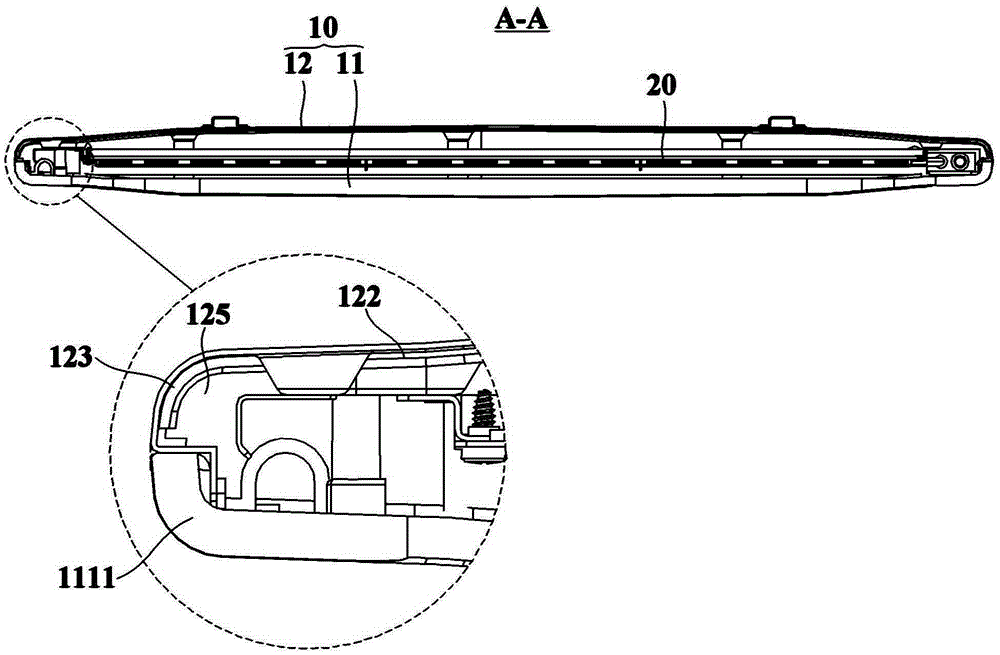

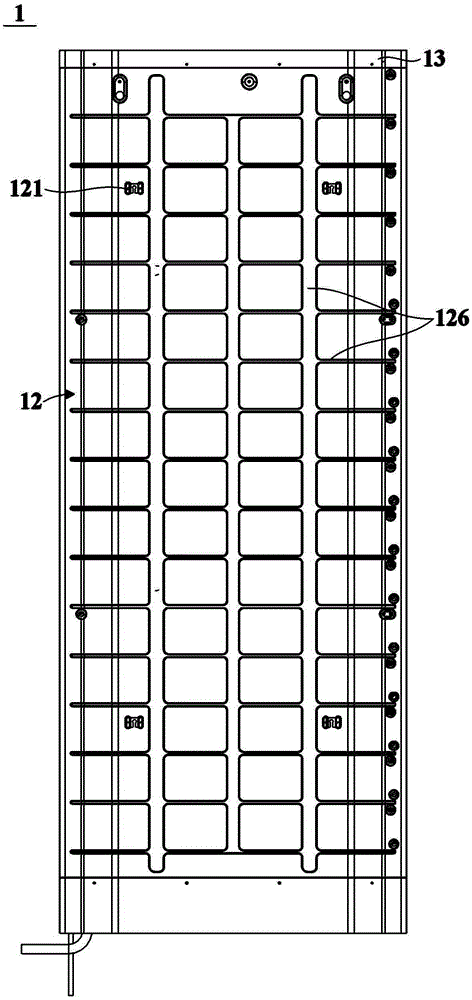

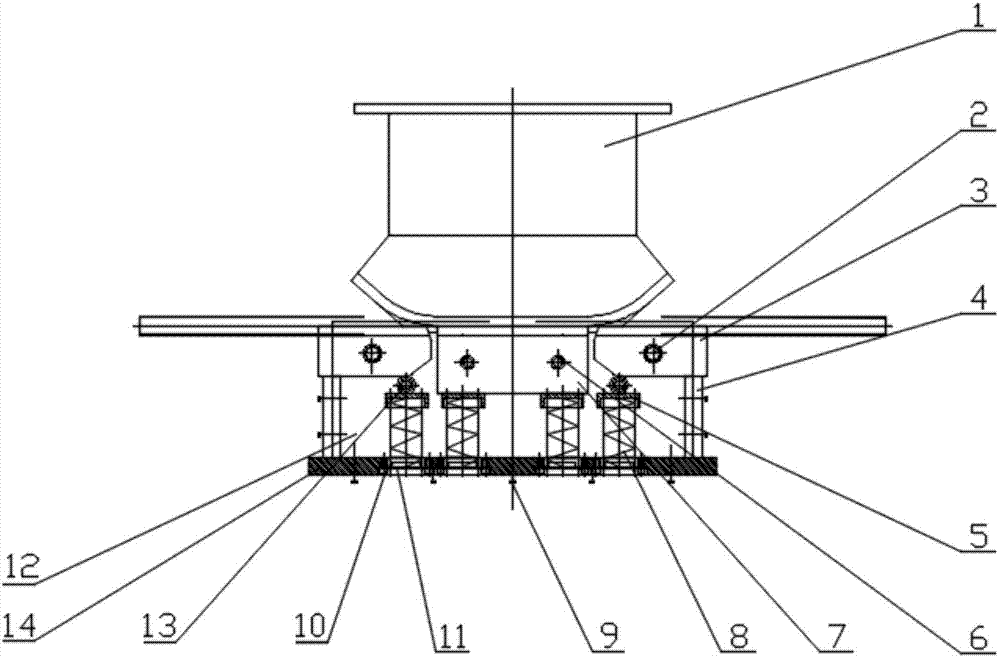

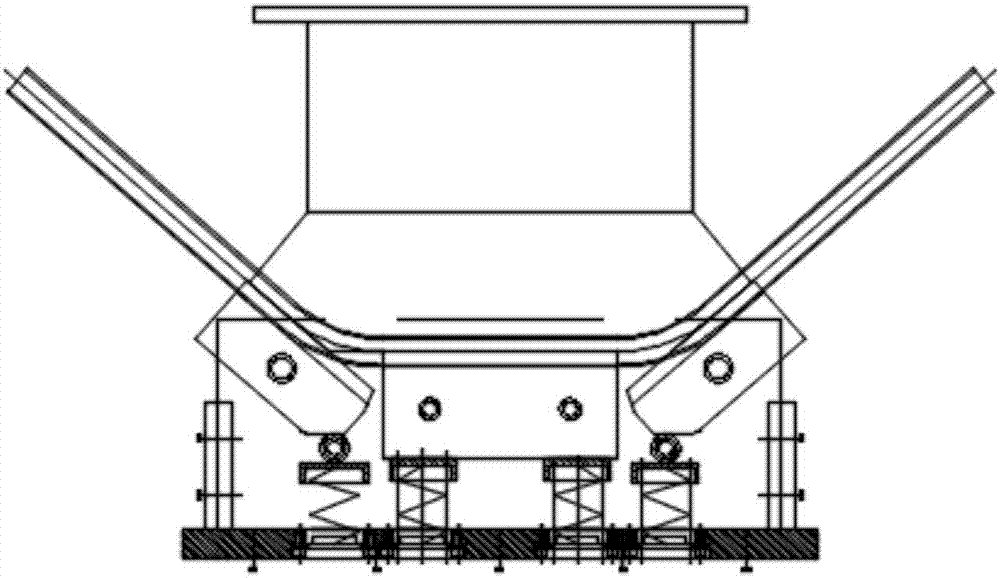

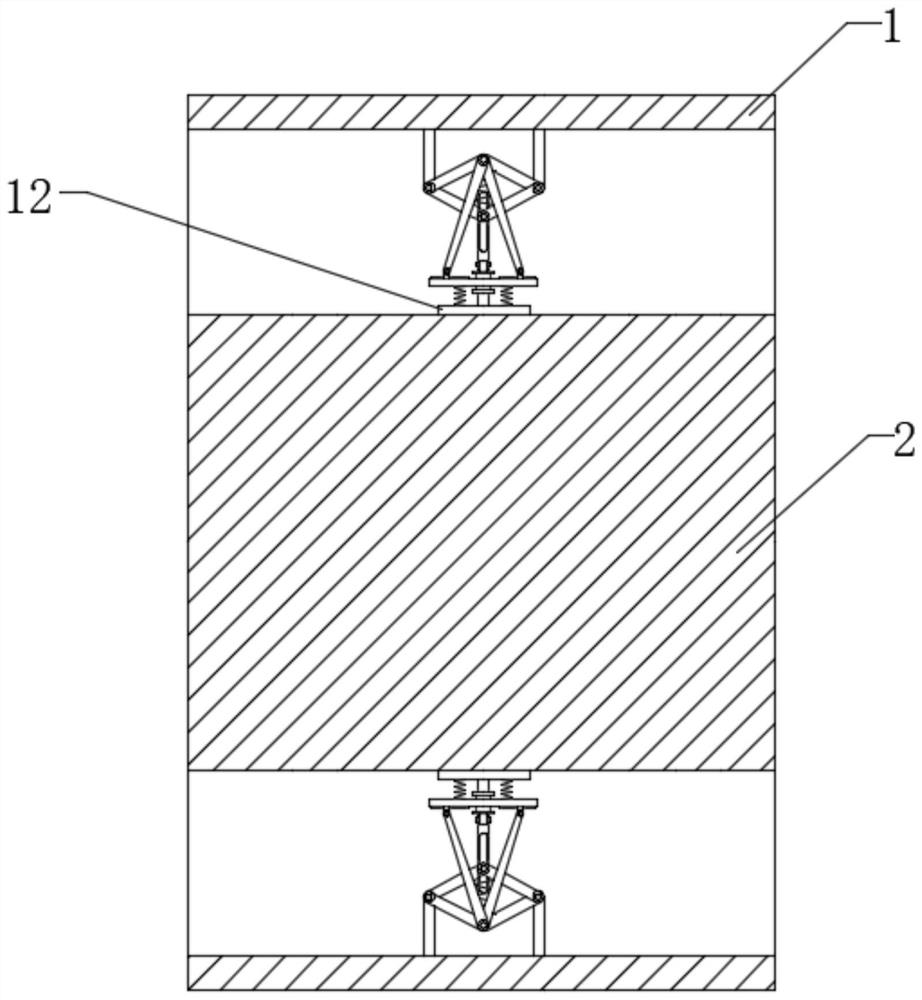

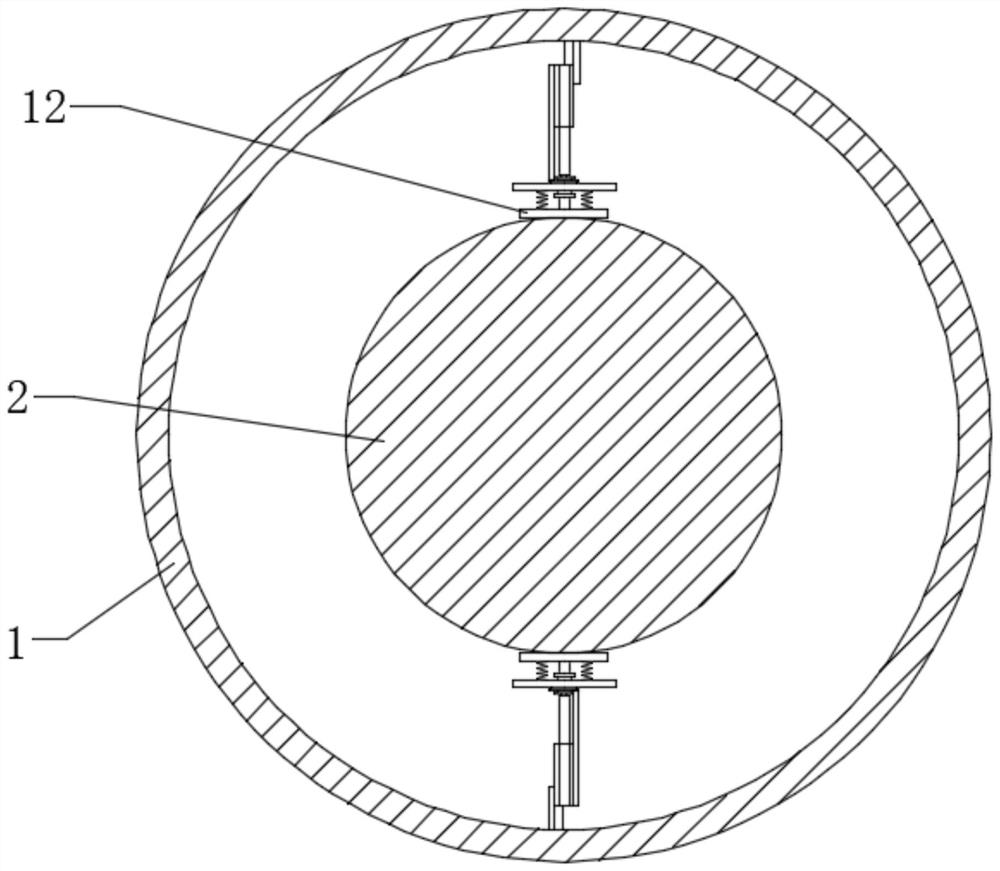

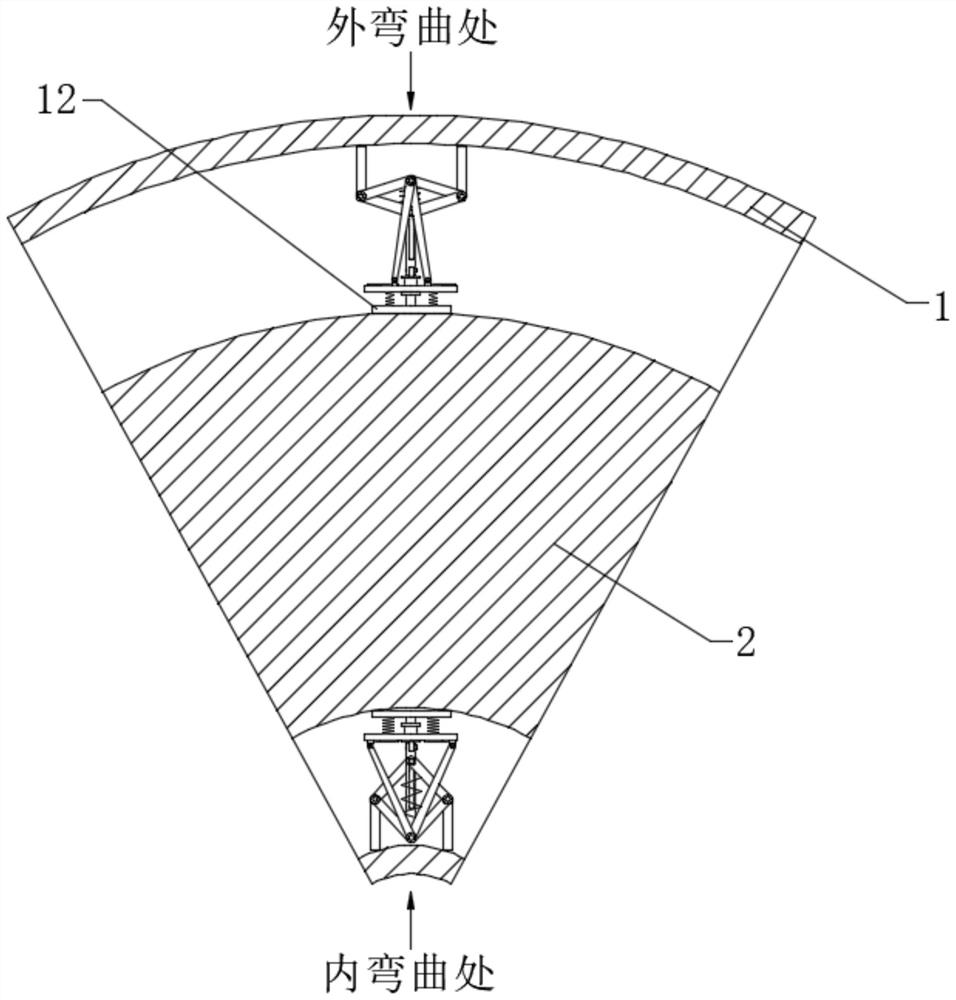

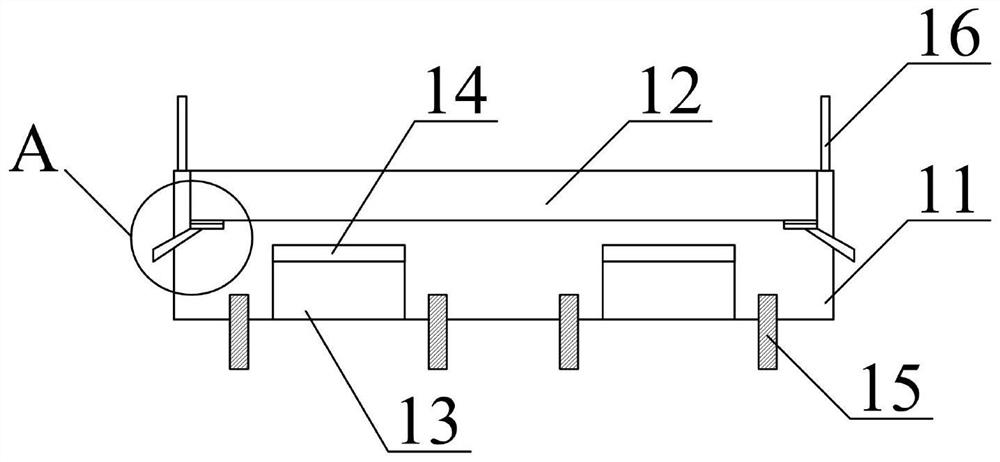

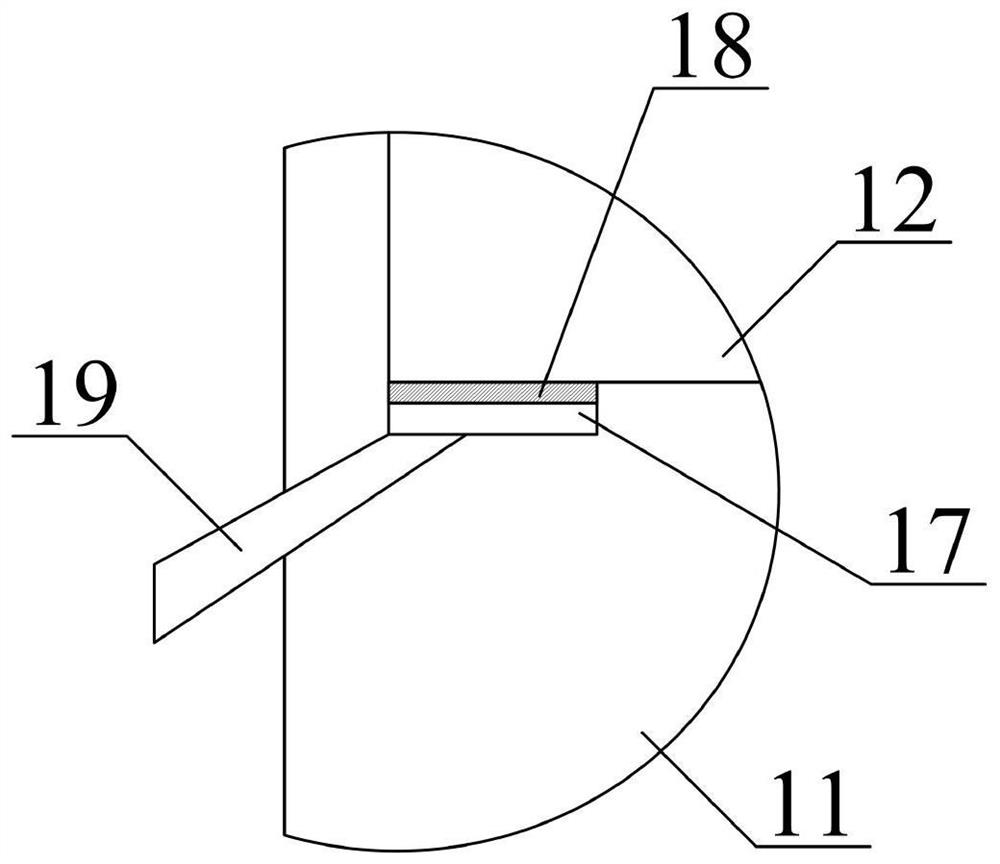

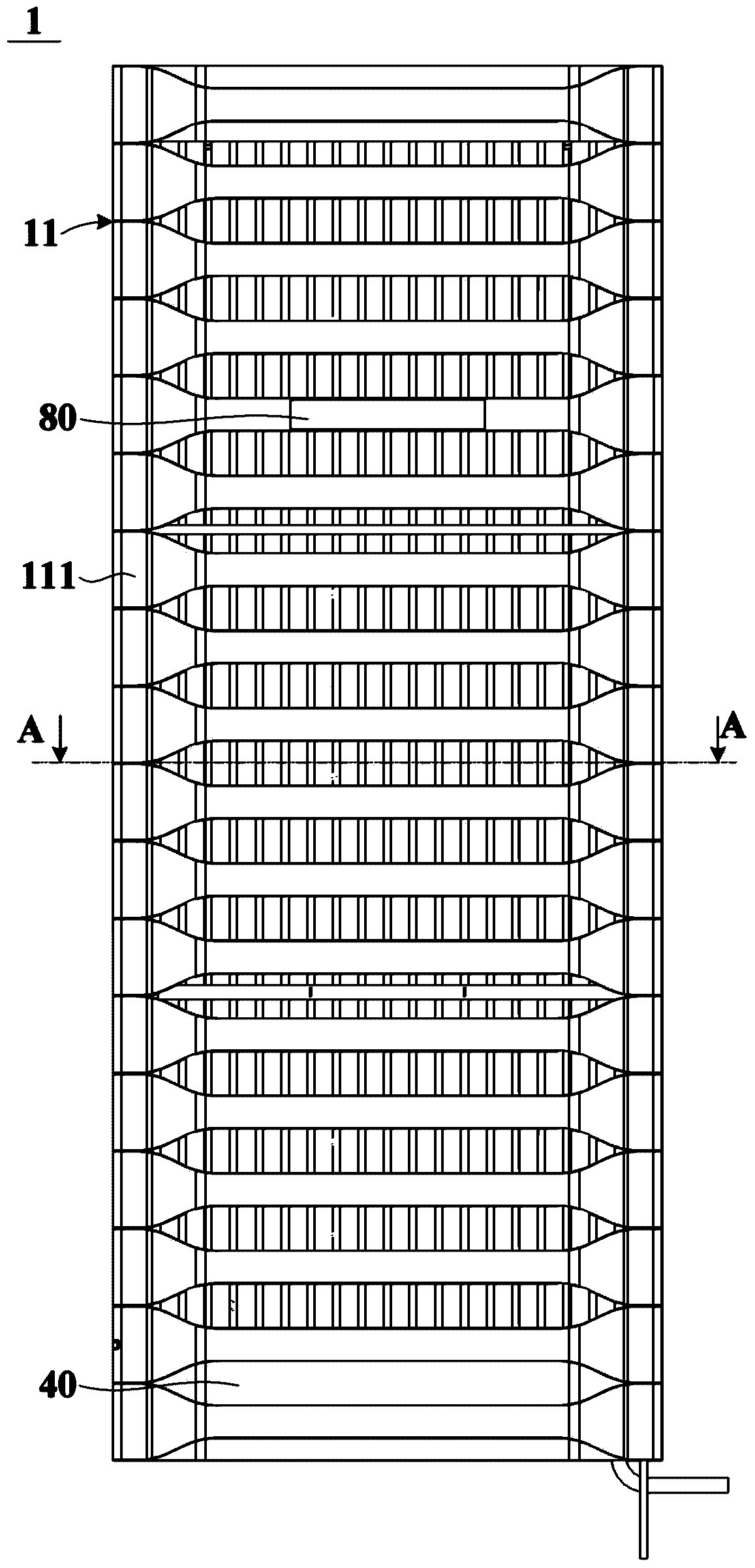

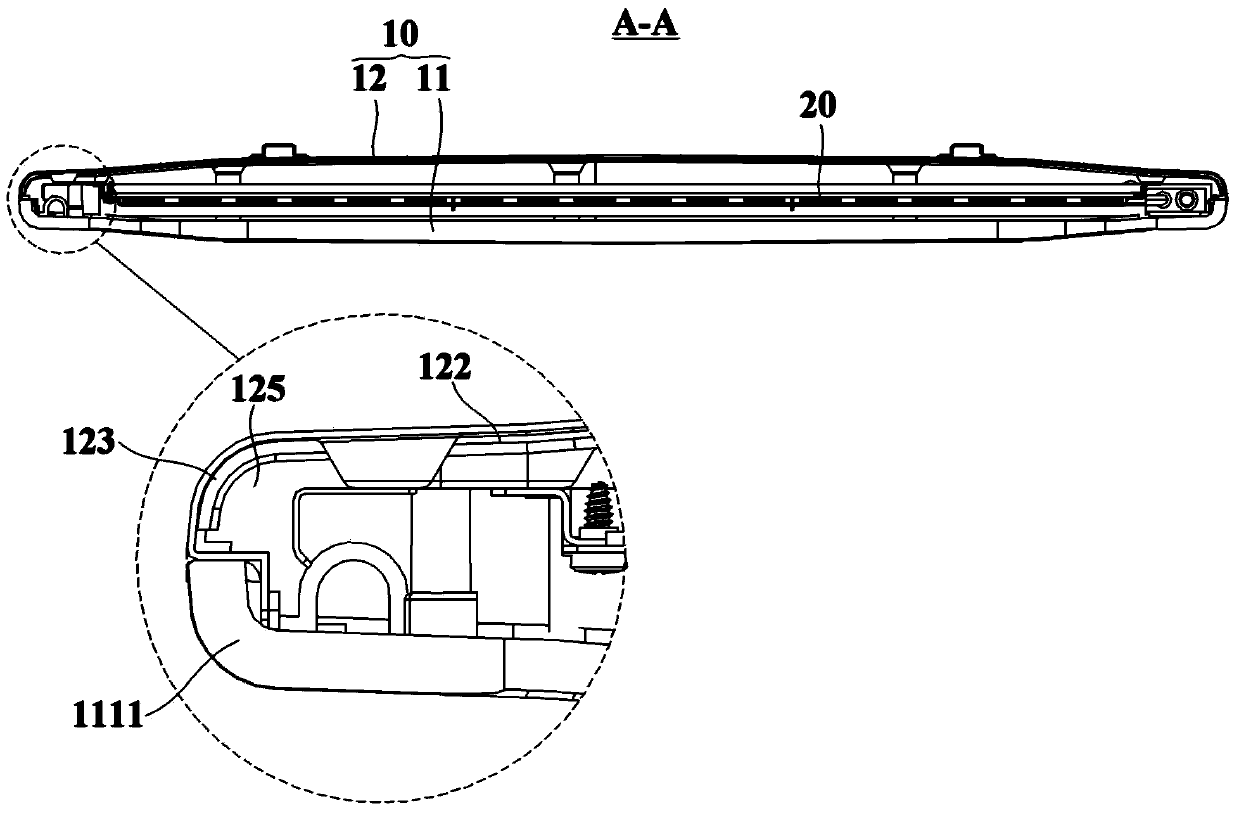

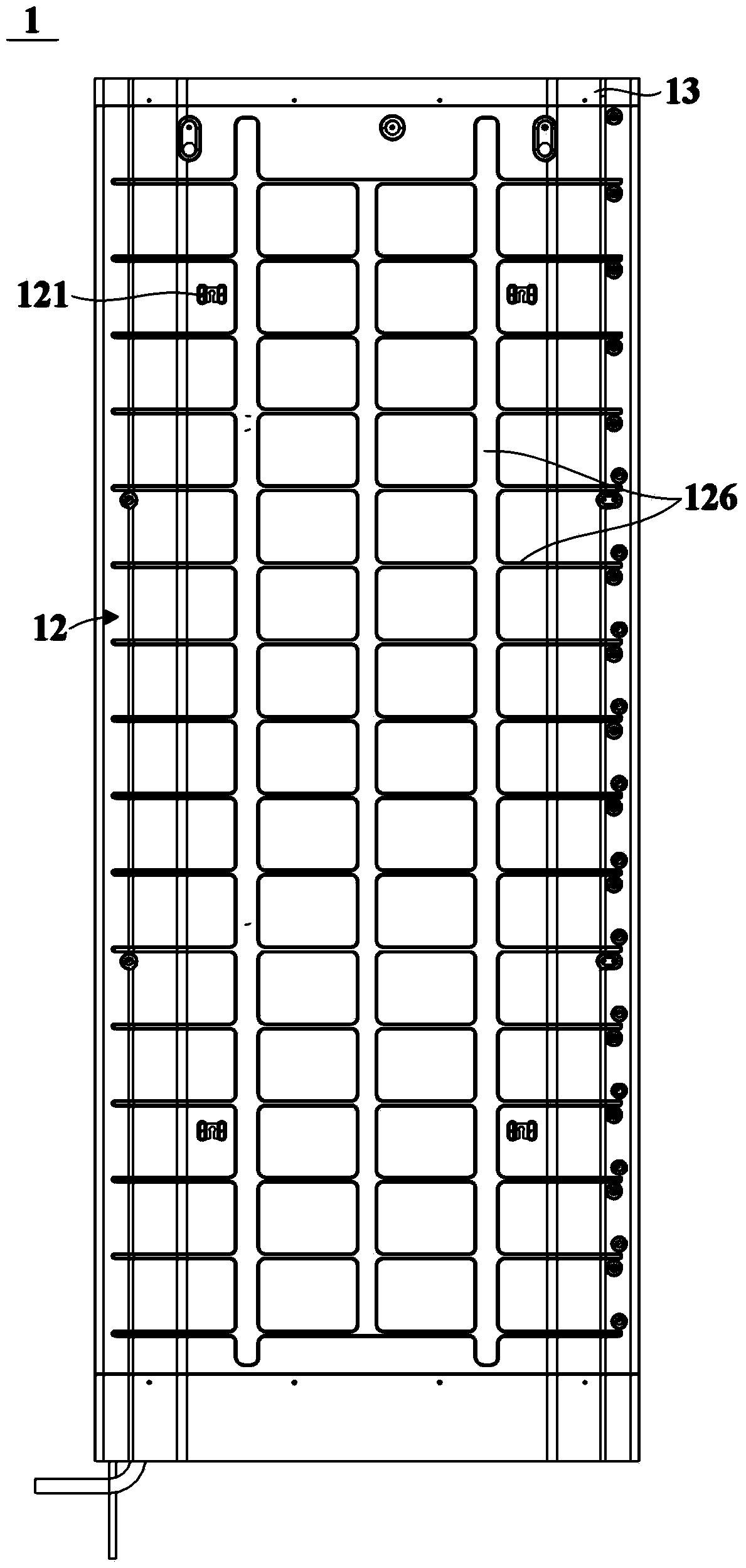

Radial type air conditioner indoor unit

ActiveCN106500174AImprove heat transfer efficiencyGuaranteed comfortLighting and heating apparatusSpace heating and ventilation detailsPlate heat exchangerEngineering

The invention relates to a radial type air conditioner indoor unit. The radial type air conditioner indoor unit comprises a shell, a micro-channel heat exchanger and a hoisting device. A containing space is formed in the shell in a limited manner. The micro-channel heat exchanger is arranged in the containing space and provided with an upper flow collecting pipe, a lower flow collecting pipe and multiple heat exchange pipes located between the upper flow collecting pipe and the lower flow collecting pipe. The hoisting device is configured in a manner that the micro-channel heat exchanger is hoisted onto the shell through the hoisting device, the upper portion of the micro-channel heat exchanger is fixed relative to the shell, and the lower portion of the micro-channel heat exchanger is movable relative to the position, in the vertical direction, of the shell. In this way, the lower portion of the micro-channel heat exchanger can be moved downwards or upwards in the vertical direction relative to the shell, so that the micro-channel heat exchanger is matched with the heat exchange pipes of the micro-channel heat exchanger in expansion and extension or contraction and shortening; the situation that the heat exchange pipes are compressed to be deformed or cracked and even ruptured at the welding positions is avoided, and thus use safety of the radial type air conditioner indoor unit is guaranteed; and appearance of the radial type air conditioner indoor unit can be more attractive.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

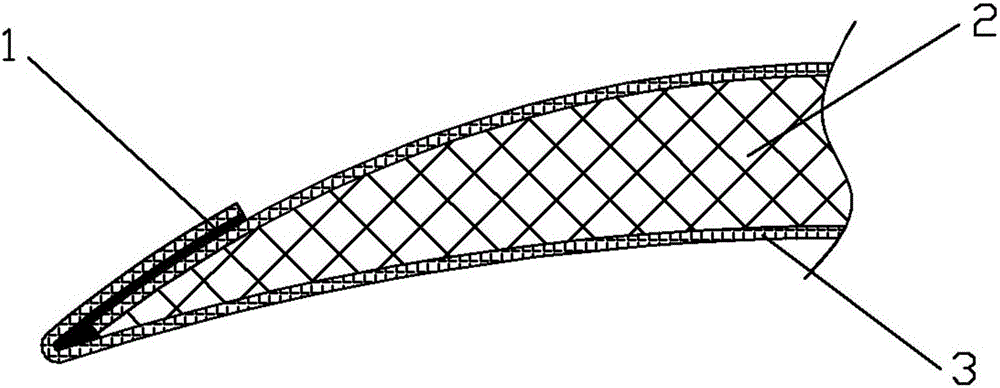

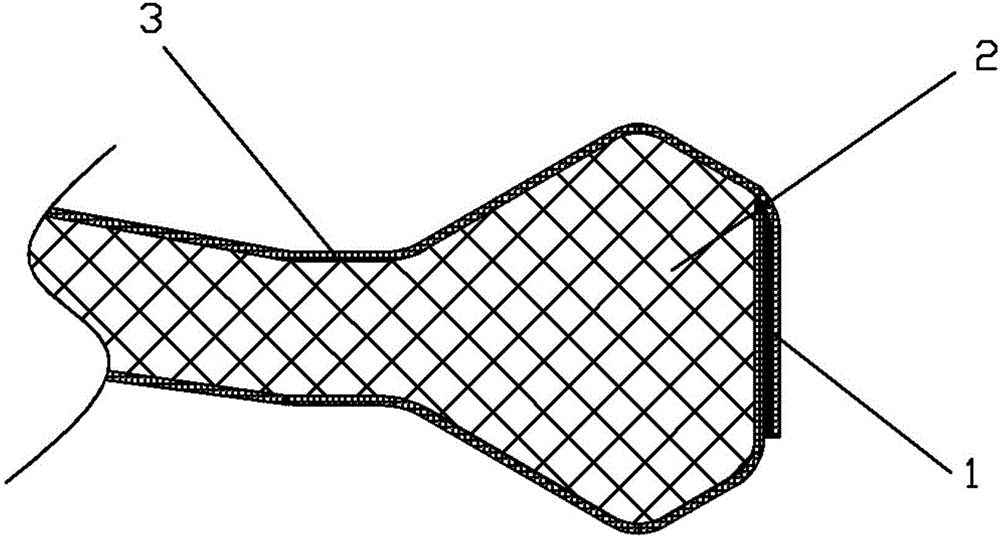

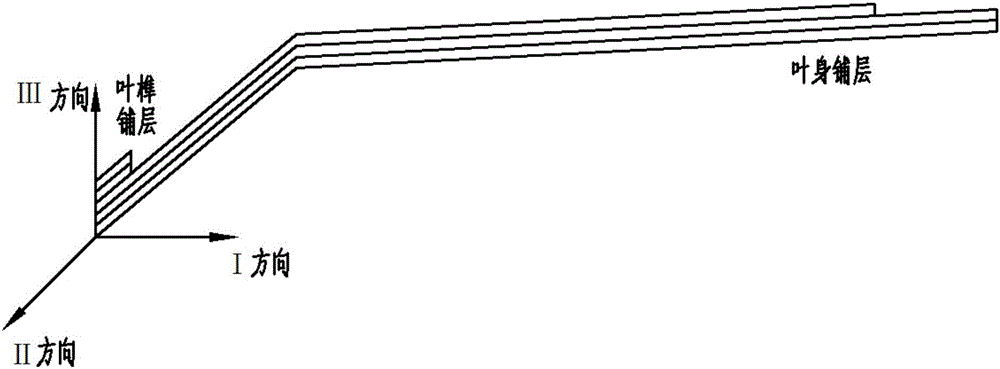

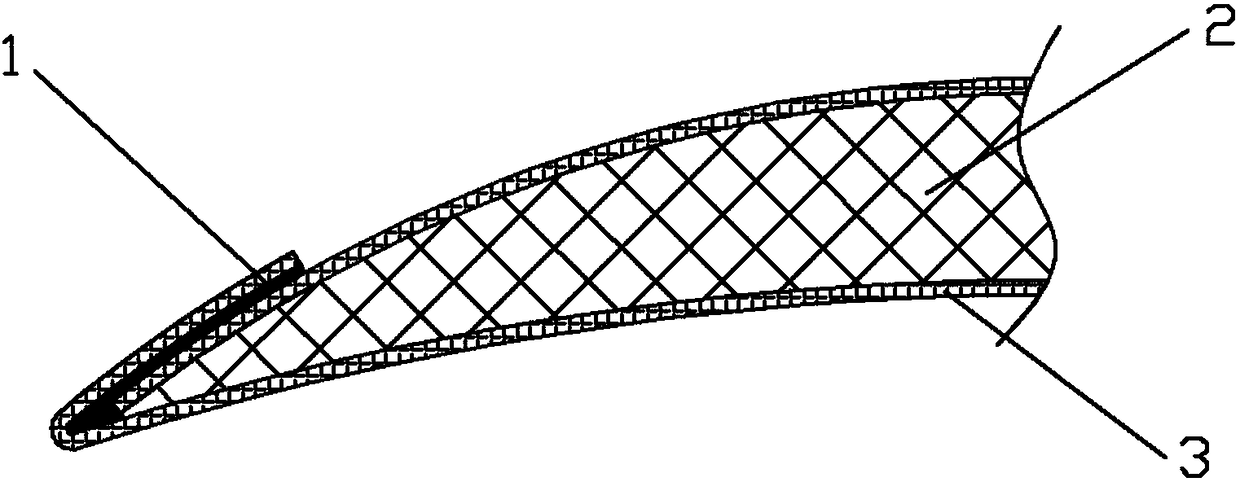

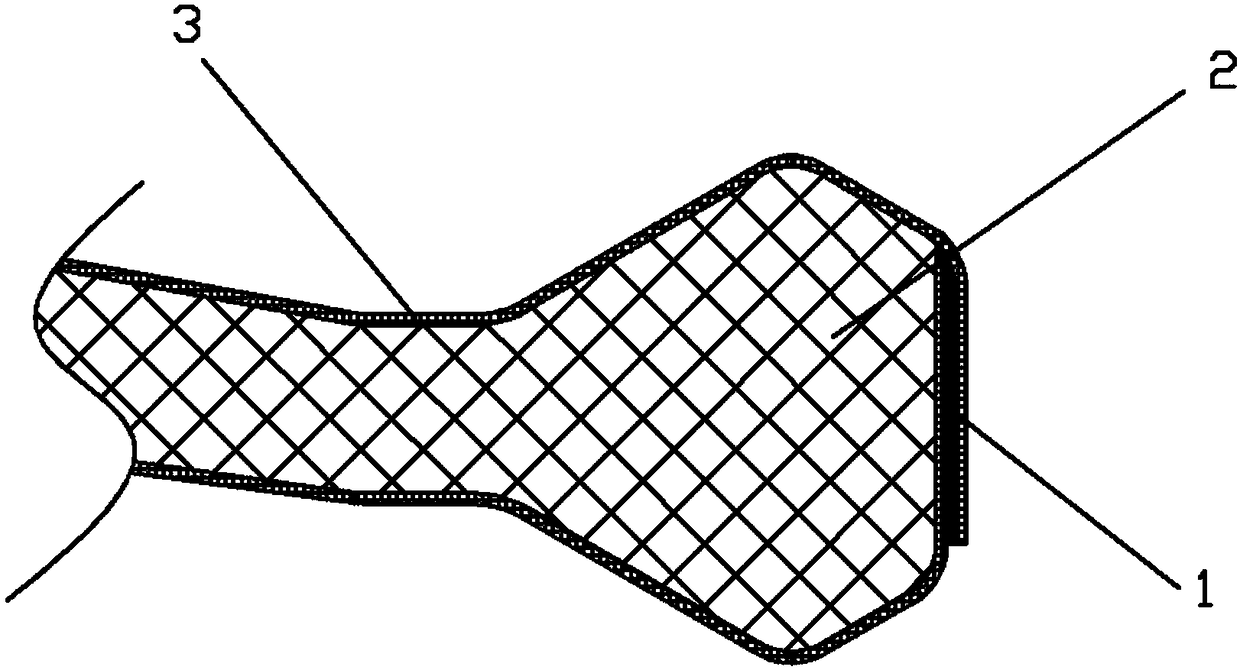

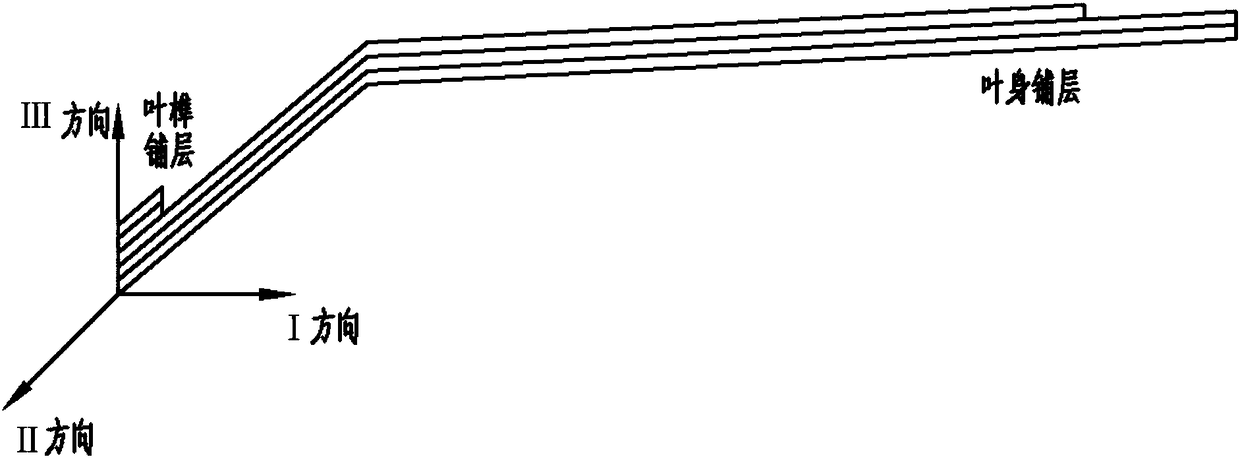

Composite gas compressor fan blade with integrated metal coating

ActiveCN106640731AConsistent temperatureUniform temperaturePump componentsPumpsMetal coatingGas compressor

The invention relates to a composite gas compressor fan blade with an integrated metal coating. The composite gas compressor fan blade is characterized by comprising a composite base layer and a metal coating, wherein the composite base layer and the metal coating are integrally formed by mould pressing; the metal coating coats the composite base layer, and the coated flange part is adhered by adopting an adhesive and set by mould pressing. The blade has very high specific strength and excellent impact resistance and erosion resistance, and can effectively avoid cracking and even breakage caused by de-mixing and surge; and the blade forming method integrates preparation of an intermediate composite material and formation of the whole blade, so that the manufacturing cost and time are greatly reduced, and the method has the advantages of high forming precision, high automation degree, long service life of the mold and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

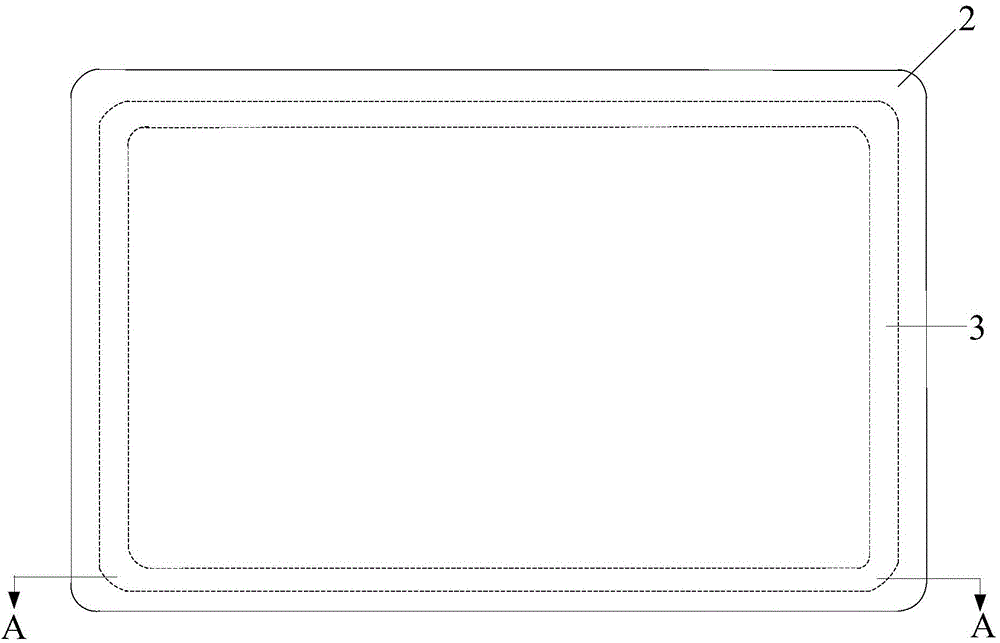

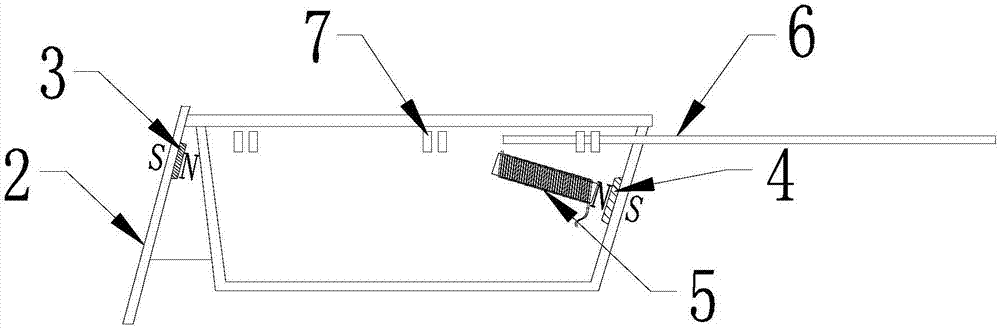

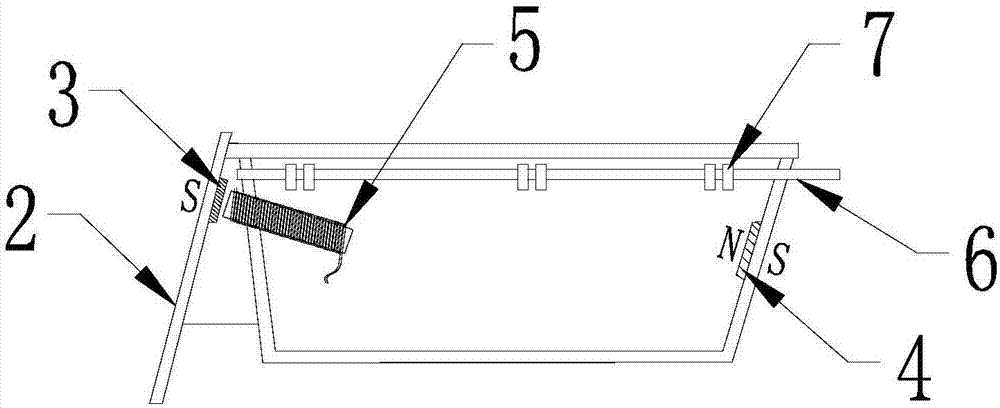

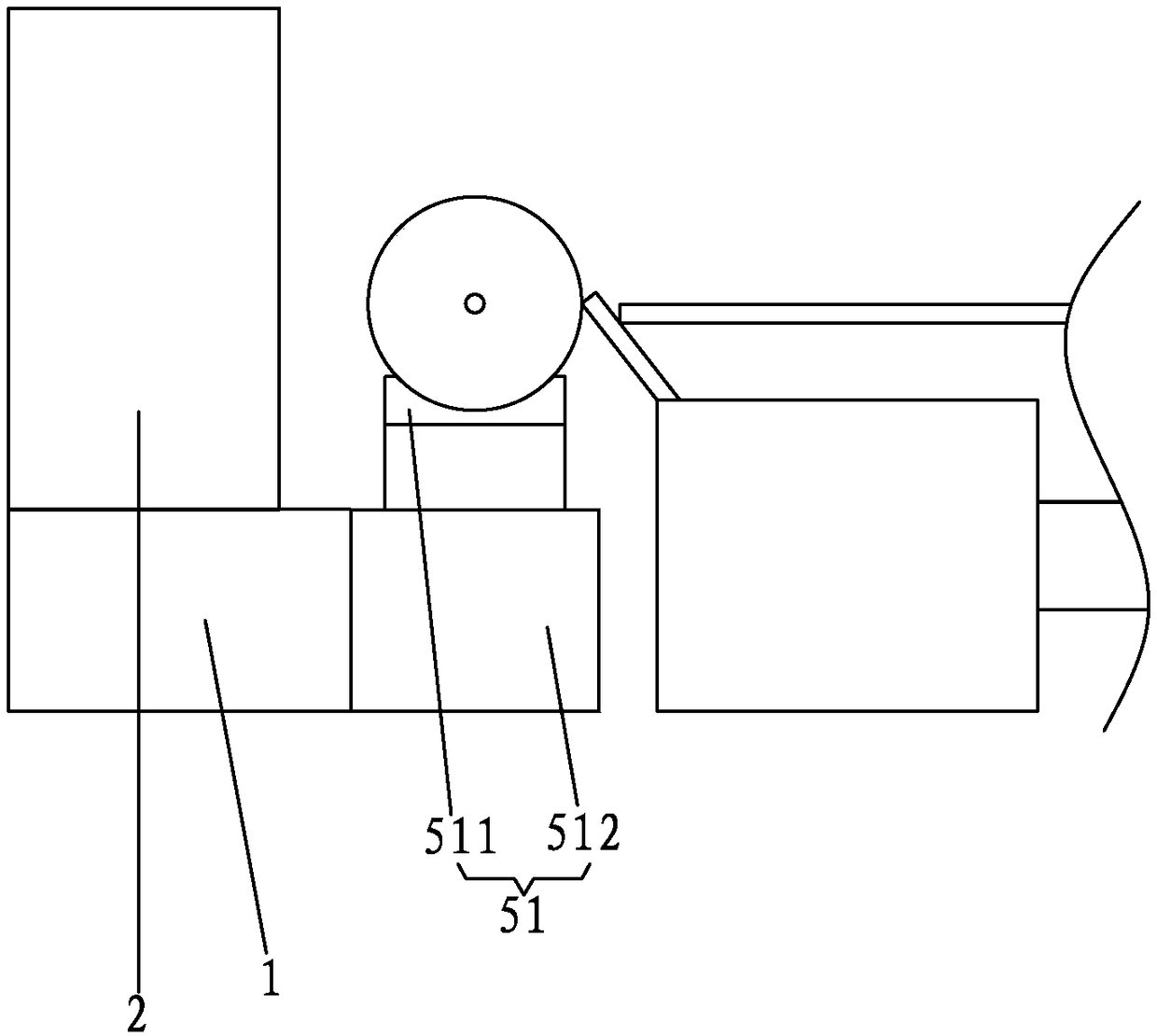

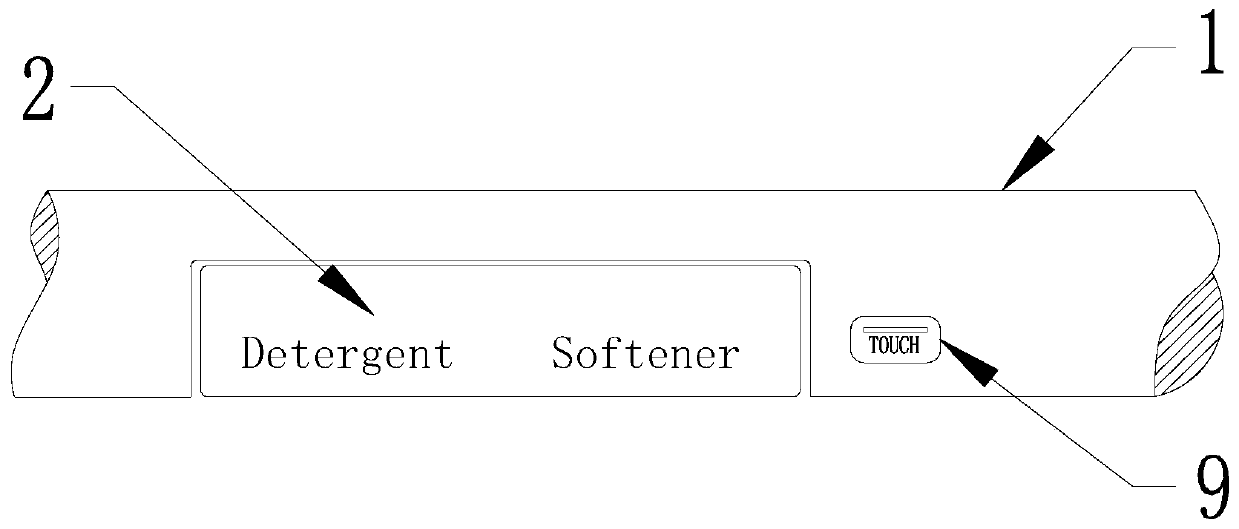

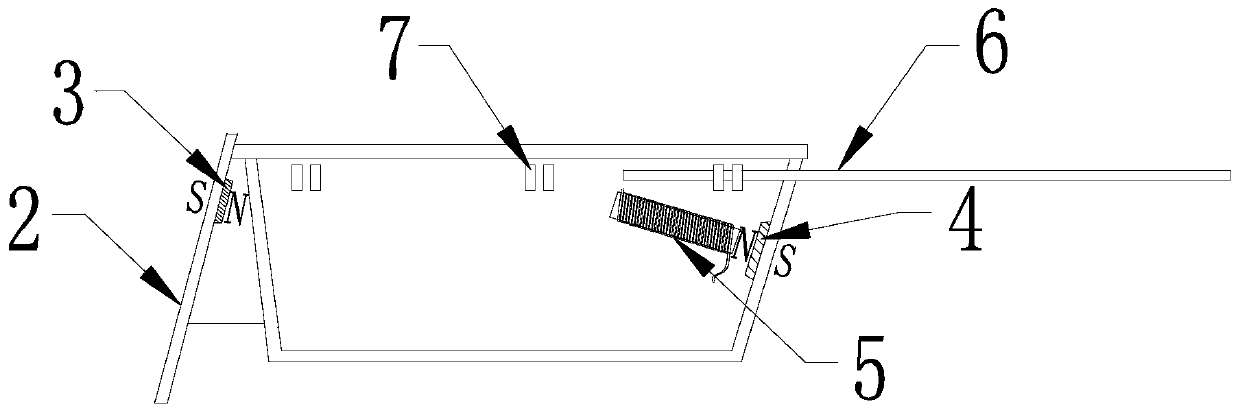

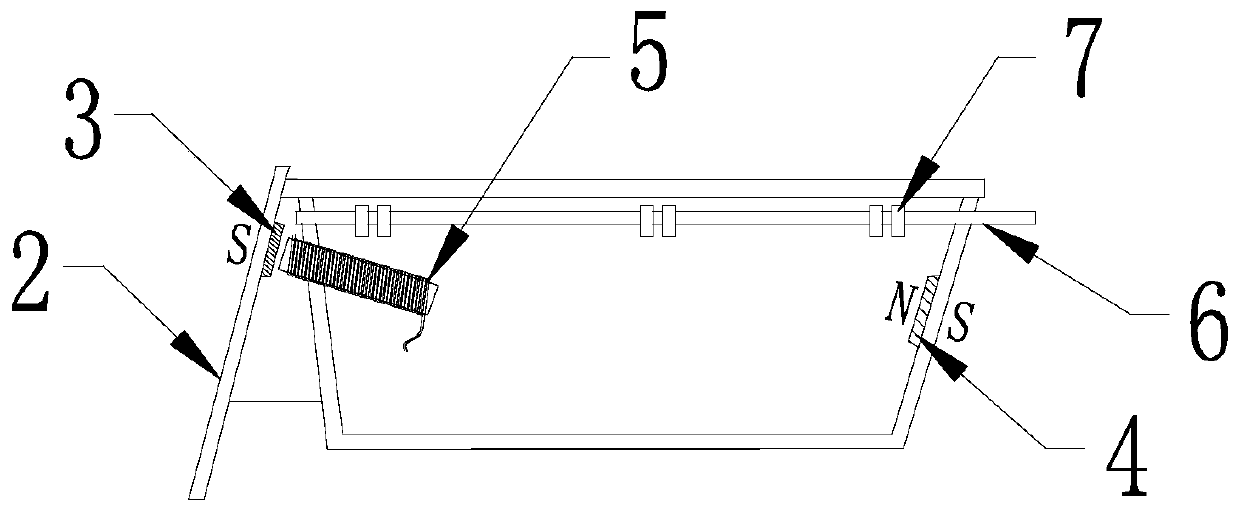

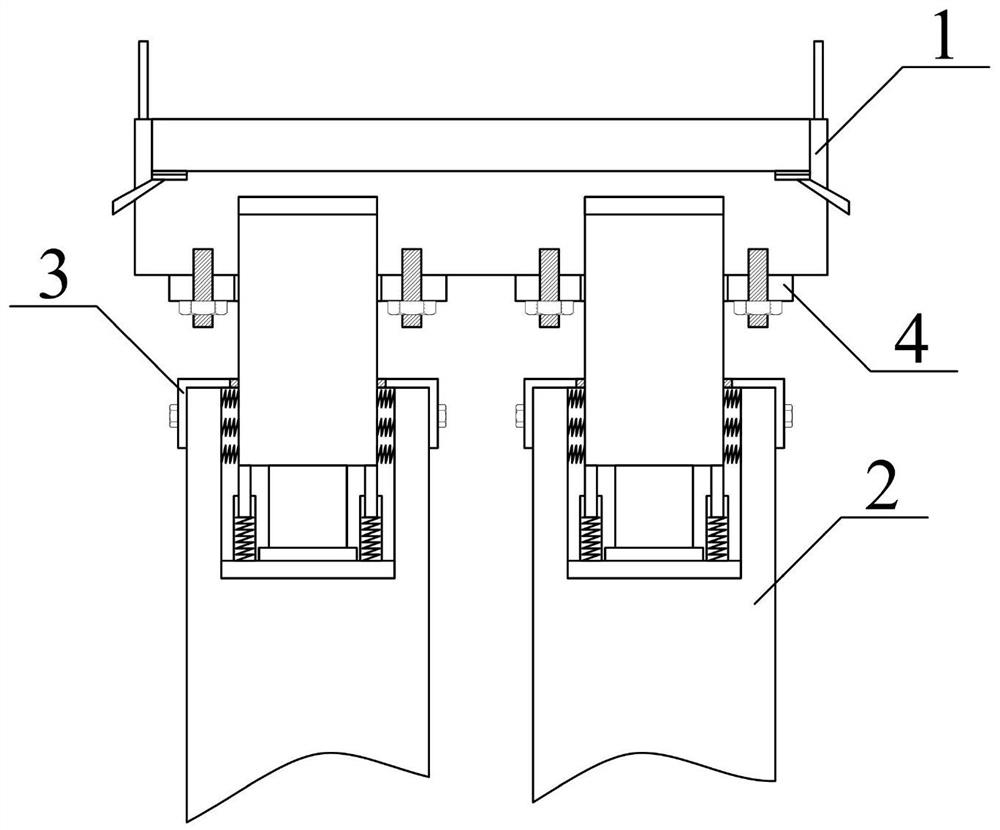

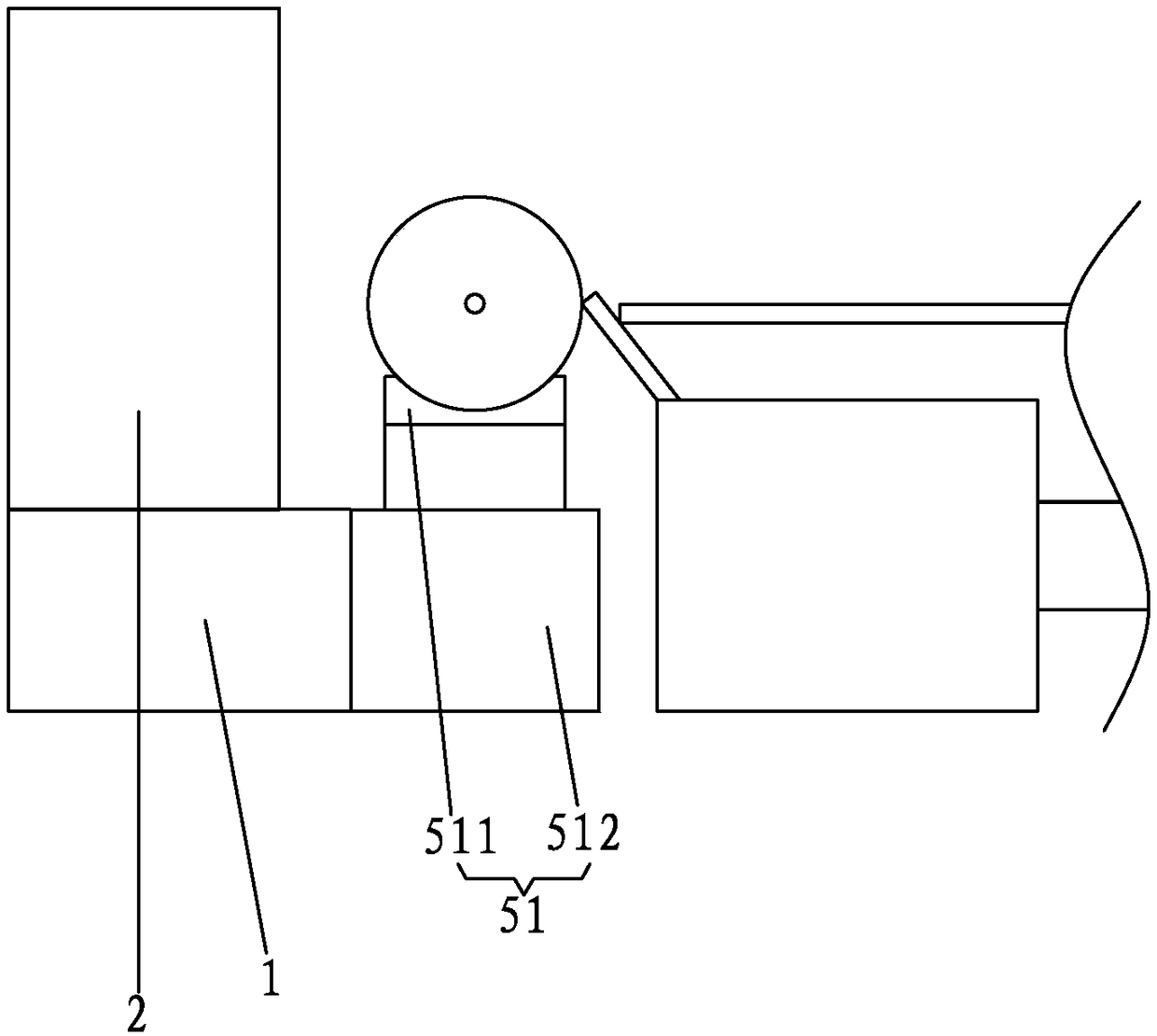

Washing machine and detergent drawer control method thereof

ActiveCN107190477AImprove user experienceReduce failure rateOther washing machinesTextiles and paperEngineeringElectromagnet

The invention discloses a washing machine and a detergent drawer control method thereof. The washing machine comprises a drawer support (1). A detergent drawer (2) capable of being pulled in a sliding mode is installed in a sliding groove of the drawer support, magnets are installed at the front end and / or the rear end of the detergent drawer in the sliding pulling direction of the detergent drawer, and an electromagnet (5) are fixedly installed on the drawer support. In the washing machine, in a power-on state, the electromagnet can achieve automatic opening or closing of the detergent drawer through magnetic force between the electromagnet and the magnets installed at the front end / or the rear end of the detergent drawer, the situation that the opening and closing structure of the detergent drawer is cracked or even broken due to mechanical fatigue after being used multiple times can be effectively avoided, therefore, the probability that the detergent drawer fails due to the fact that the detergent drawer cannot be opened or closed is reduced, and the use experience of a user on the washing machine is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

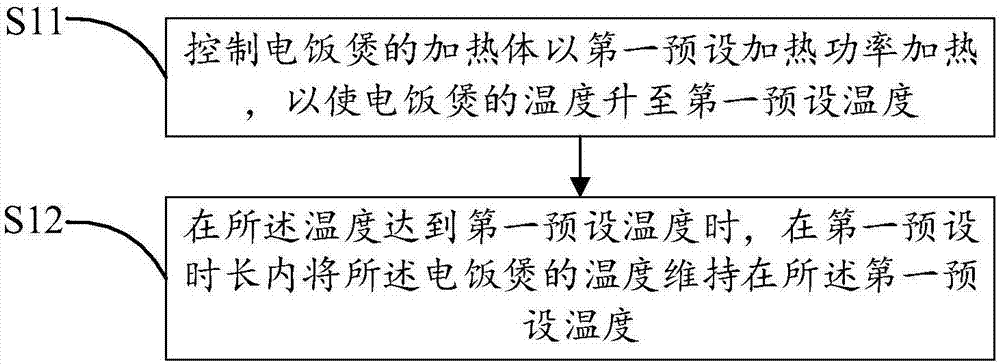

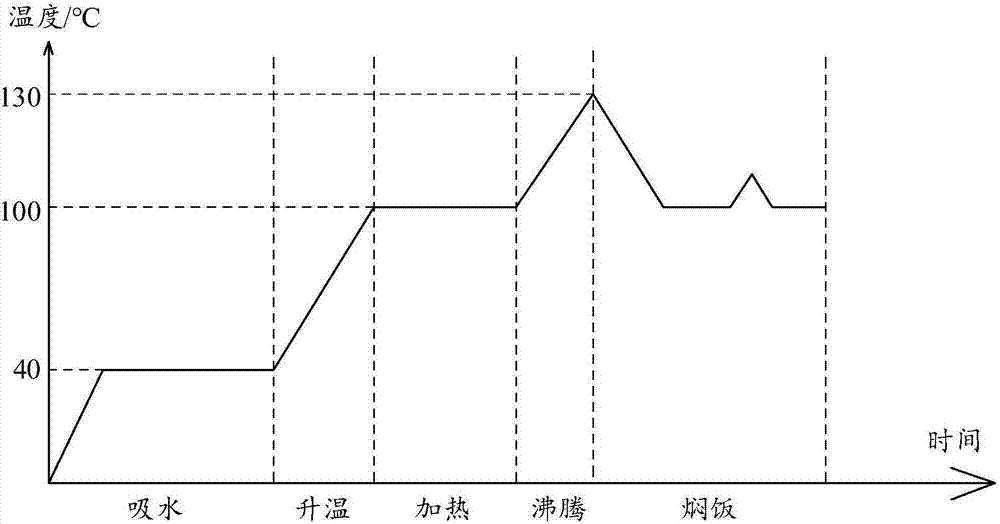

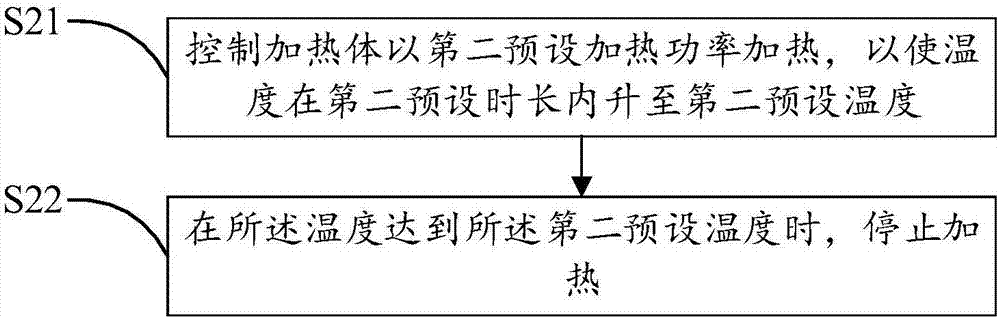

Control method for rice cooking of rice cooker and rice cooker

InactiveCN107296479AAvoid pinchingImprove water absorption efficiencyTemperatue controlVessels with intergral heatingEngineeringRice protein

The invention discloses a rice cooking control method for an electric rice cooker, which comprises the following cooking stages: a water absorption stage, a heating stage, a heating stage, a boiling stage and a rice stewing stage; When the amylose content is set and the protein content is greater than the preset protein content, the water absorption stage includes: controlling the heating body of the electric rice cooker to heat with the first preset heating power; when the temperature reaches the first preset temperature, The temperature of the electric rice cooker is maintained at the first preset temperature for a first preset time period. The invention also discloses an electric rice cooker. The invention enables the indica rice whose amylose content is greater than the preset amylose content and whose protein content is greater than the preset protein content to fully absorb water at a reasonable temperature within the first preset time length, thereby improving the water absorption efficiency of the indica rice, and further Improves the taste of rice.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

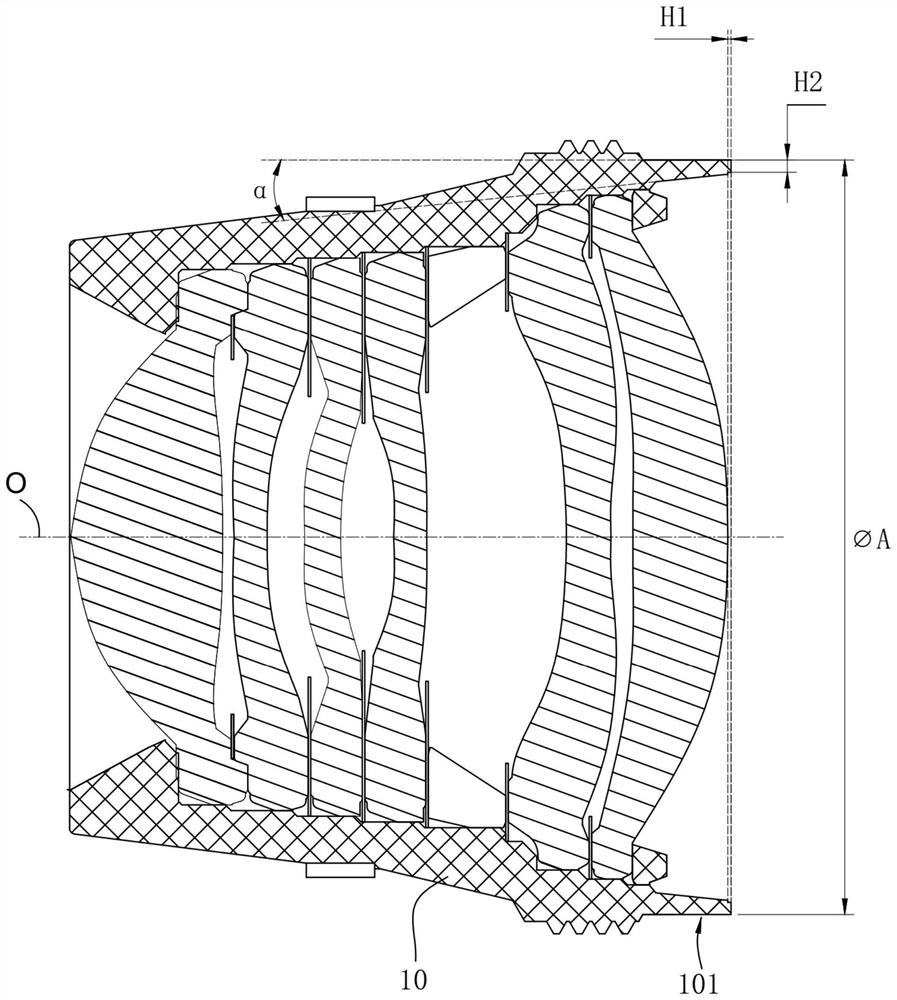

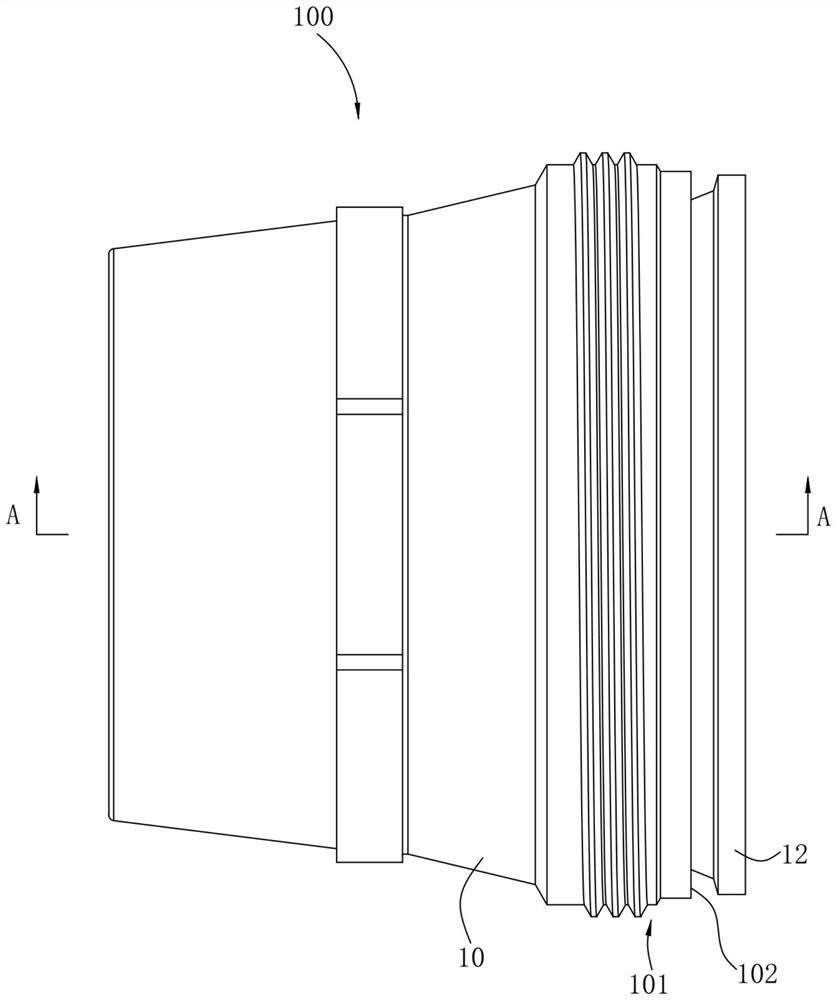

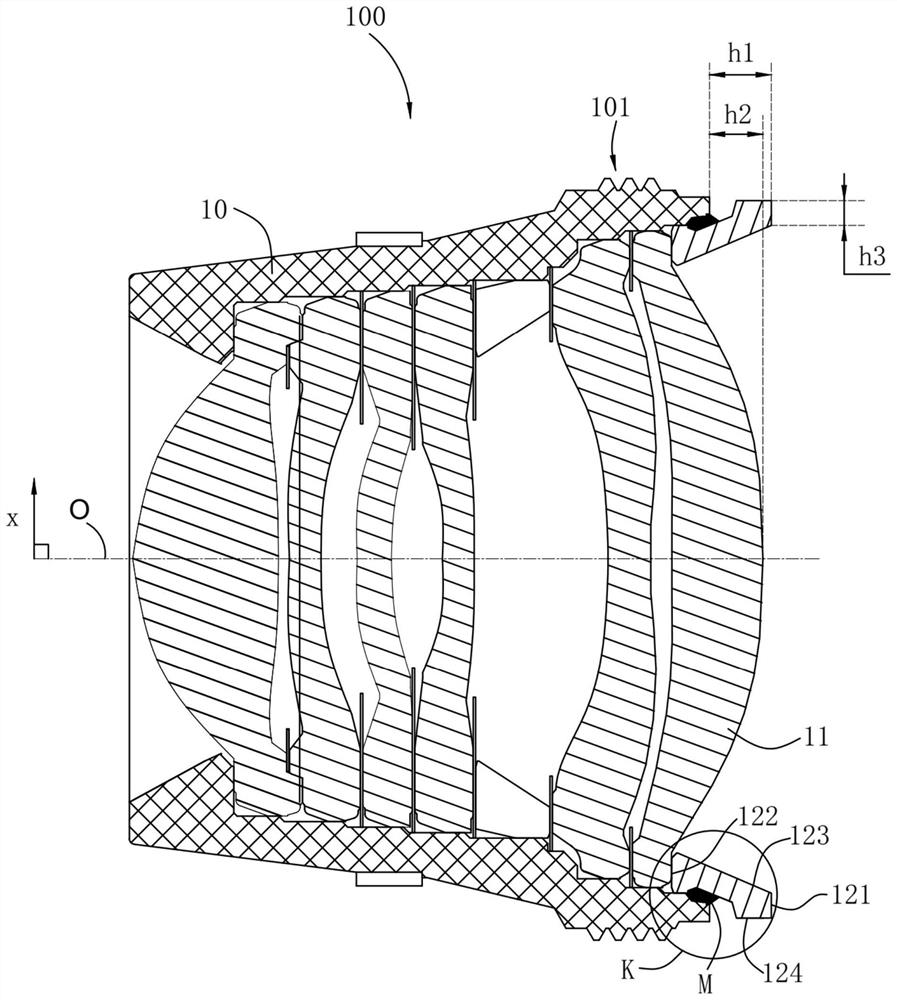

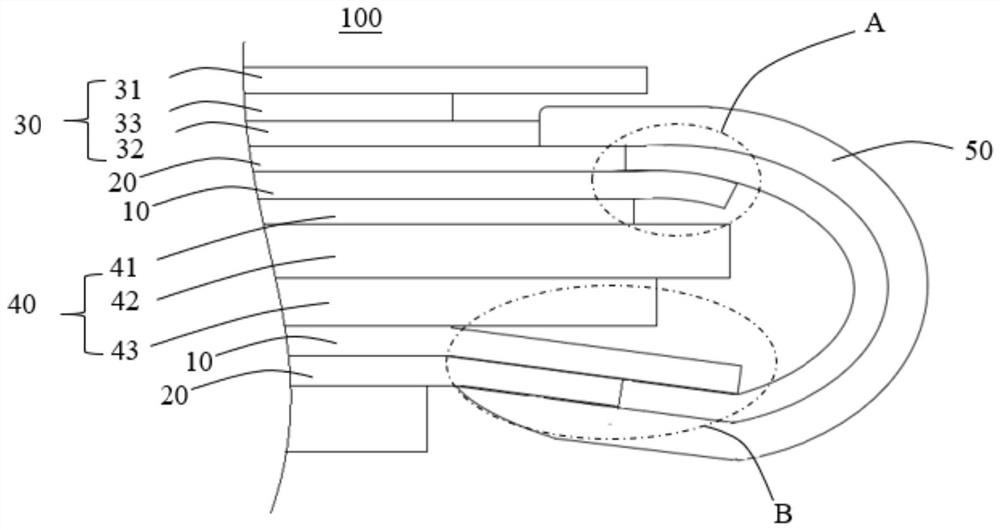

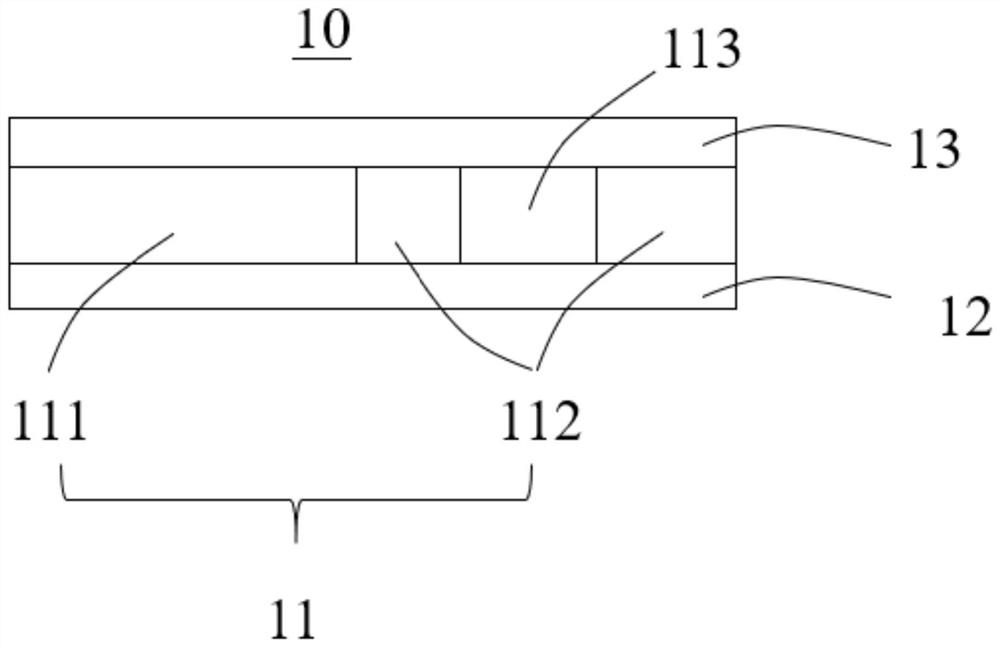

Lens structure, camera module and electronic equipment

The invention discloses a lens structure, a camera module and electronic equipment, the lens structure comprises a lens cone, an optical lens and a compression ring, the optical lens is arranged in the lens cone, the compression ring is arranged at the image side end of the lens cone and extends out of the lens cone from the inside of the lens cone, and the first end face of the compression ring is located outside the lens cone, in the optical axis direction, the distance between the first end face and the image side face of the lens barrel is larger than the distance between the point, farthest from the object side face of the lens barrel, of the optical lens and the image side face of the lens barrel, the second end face of the pressing ring is located in the lens barrel and is opposite to the first end face, the inner circumferential face of the pressing ring is a conical face arranged around the optical axis, the inner diameter of the compression ring is gradually increased in the direction from the object side end of the lens barrel to the image side end of the lens barrel, and a first chamfer is arranged at the joint of the inner circumferential surface and the second end surface. By adopting the scheme, the optical lens can be prevented from protruding out of the pressing ring while the stable forming of the lens cone is ensured, and the pressing ring is used for protecting the optical lens, so that the risks of scratching and polluting the optical lens are reduced; and the imaging quality can be improved.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

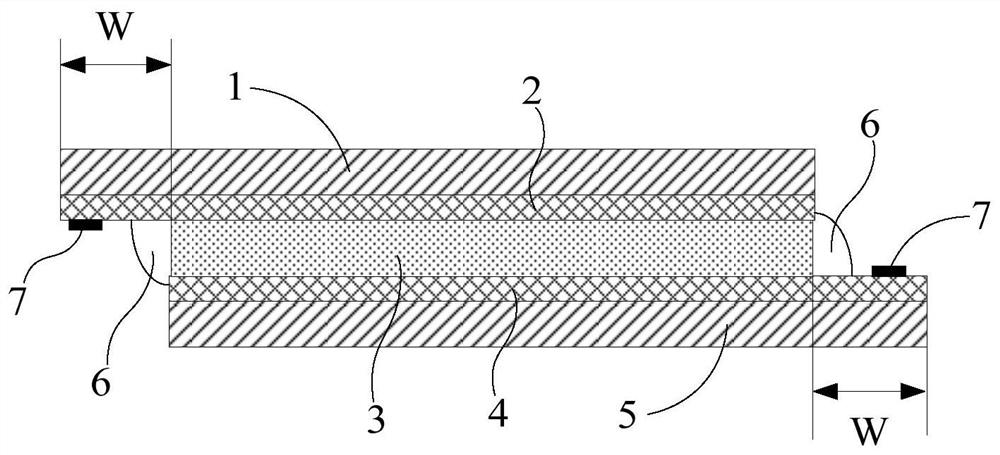

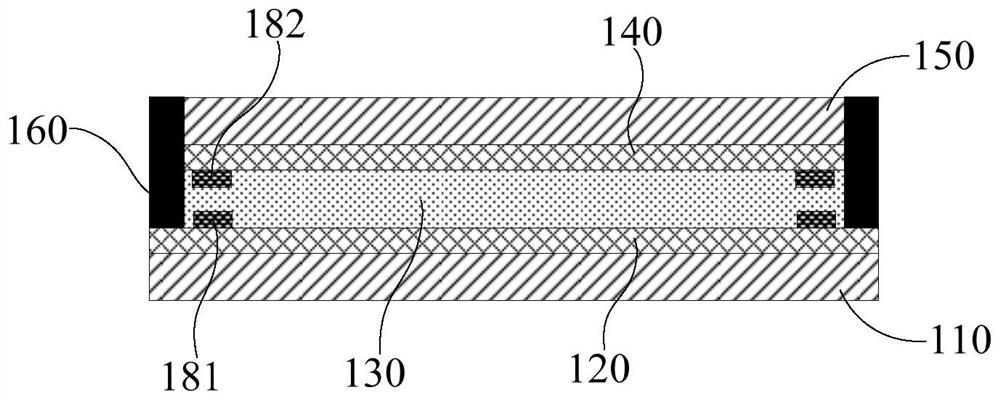

Display module and manufacturing method thereof

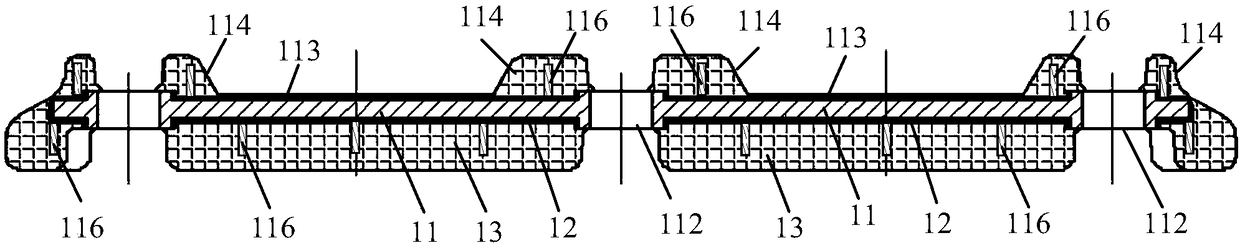

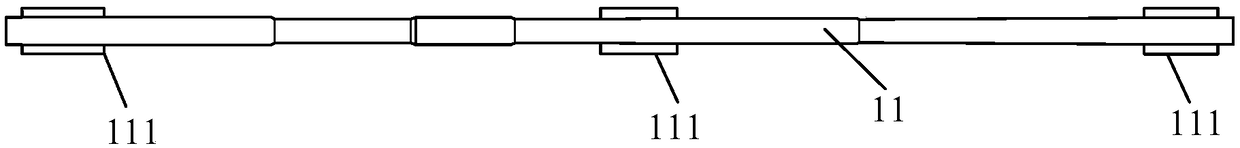

ActiveCN113593415AImprove stiffnessImprove subsidenceIdentification meansElectrical apparatus contructional detailsMechanical engineering

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Composite compressor fan blade with integral metal cladding

ActiveCN106640731BConsistent temperatureUniform temperaturePump componentsPumpsMetal coatingAdhesive

The invention relates to a composite gas compressor fan blade with an integrated metal coating. The composite gas compressor fan blade is characterized by comprising a composite base layer and a metal coating, wherein the composite base layer and the metal coating are integrally formed by mould pressing; the metal coating coats the composite base layer, and the coated flange part is adhered by adopting an adhesive and set by mould pressing. The blade has very high specific strength and excellent impact resistance and erosion resistance, and can effectively avoid cracking and even breakage caused by de-mixing and surge; and the blade forming method integrates preparation of an intermediate composite material and formation of the whole blade, so that the manufacturing cost and time are greatly reduced, and the method has the advantages of high forming precision, high automation degree, long service life of the mold and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Engineering pipe pile foundation

ActiveCN108797593APrevent dumpingGuaranteed verticalityBulkheads/pilesArchitectural engineeringEngineering

The invention discloses an engineering pipe pile foundation, and belongs to the field of building construction. According to the technical scheme, the foundation comprises a fixed net, a fixed devicefixedly arranged in the fixed net, a prefabricated pile fixed into the fixed device and a stress device arranged on the prefabricated pile. The fixed net is composed of a frame and cross beams, the cross beams have the longitudinal cross beam and the transverse cross beam, the longitudinal cross beam and the transverse cross beam are crossed, the stress device comprises a stress cylinder arrangedat the upper end of the prefabricated pile in a sleeving manner and a ring fixed to the lower end of the stress cylinder, the inner ring of the ring is attached to the outer surface of the prefabricated pile, and multiple guide piles are evenly fixed to the lower surface of the ring. The problem that the pipe pile foundation is prone to knowing down is solved, and the effect of preventing the pipepile foundation from toppling and breaking is achieved.

Owner:YONGJIA ZHONGHONG CONSTR

Rotary cutting mechanism with efficient and continuous rotary cutting function

ActiveCN108724403AAvoid uneven forcePrevent deviationVeneer manufactureElectric machineryKnife blades

Owner:漳州市炯辉机械有限公司

Automatic precise rotary cutting device

ActiveCN108673688APrecise positioningEasy to holdProfiling/shaping machinesVeneer manufactureMotor driveEngineering

The invention provides an automatic precise rotary cutting device. According to the rotary cutting device, before the rotary cutting device starts rotary cutting work, a first lifting driving device slides in the direction far away from a second clamping part along a first horizontal guide rail, a first lower telescopic supporting rod and a second lower telescopic supporting rod slide to be in contact with a log in a top abutting mode, the log is supported to be in contact with an upper driving wheel single body in a top abutting mode, a first advancing and retreating motor drives a first rotating shaft to move in the direction away from a second clamping part, a first lifting frame moves to the position where the height of a first cutting knife corresponds to the height of the circle center of the log, working personnel rotate a first operation handle for adjustment, then a first clamping arm clamps the log, a controller controls driving of a first lifting motor, so that the pressureof a first main base plate to the first lifting frame before the round log is clamped is equal to the pressure after the round log is clamped, then the first lifting driving device slides in the direction close to the second clamping part along the first horizontal guide rail, the first rotating shaft moves in the direction close to the second clamping part, and then the first cutting knife and the log are aligned automatically.

Owner:漳州市炯辉机械有限公司

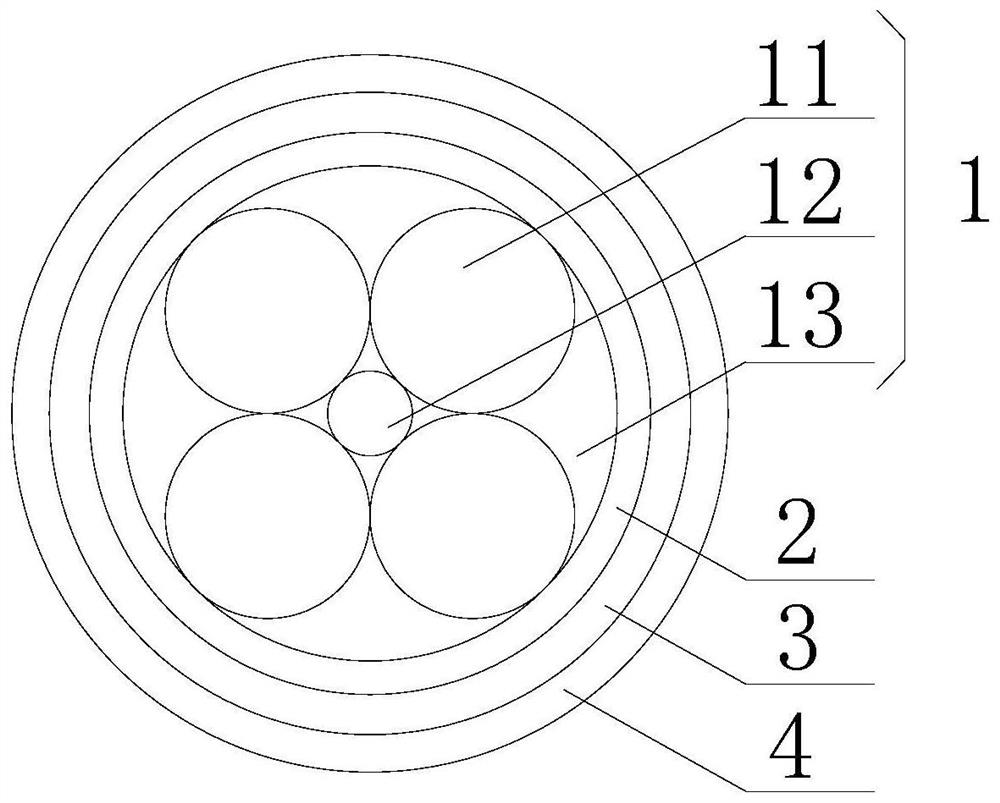

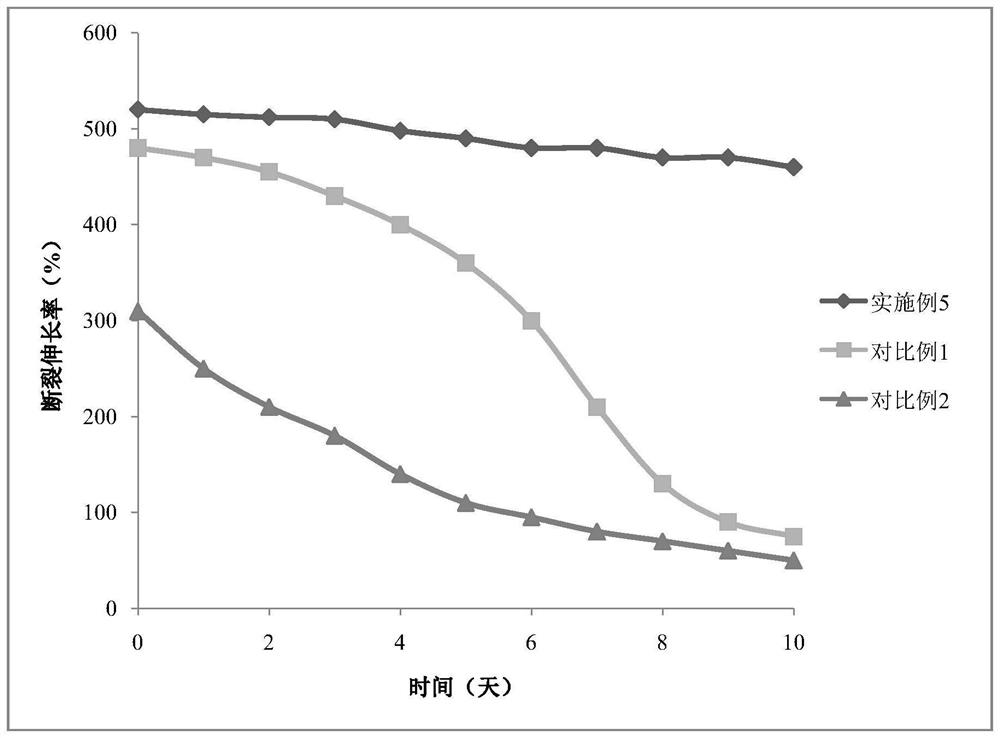

Flexible control cable for industrial robot

InactiveCN113308063AExcellent dielectric propertiesGood chemical stabilityFlexible cablesFlexible conductorsCrazingPolyvinyl chloride

The invention discloses a flexible control cable for an industrial robot. The flexible control cable comprises a wire core, and an insulating layer, a shielding layer and an outer protective layer which are sequentially coated outside the wire core, the wire core comprises a plurality of wires, positioning pieces arranged among the plurality of wires, and filling fluid filled between the plurality of wires and the insulating layer; and the outer protective layer is made of flexible heat-resistant soft polyvinyl chloride plastics. When the cable is bent in the using process, the tensile force or torsional force borne by the cable can be converted into movement of the cable, when the cable is strongly impacted, the toughness of the cable core is enhanced, the cable flexibility can be maintained in a high-temperature environment for a long time in cooperation with the effect of the surface outer protection layer, and damage to the surface of the cable caused by stress concentration is effectively reduced; and the conditions of cracks and even breakage are avoided.

Owner:合肥必更赢科技有限公司

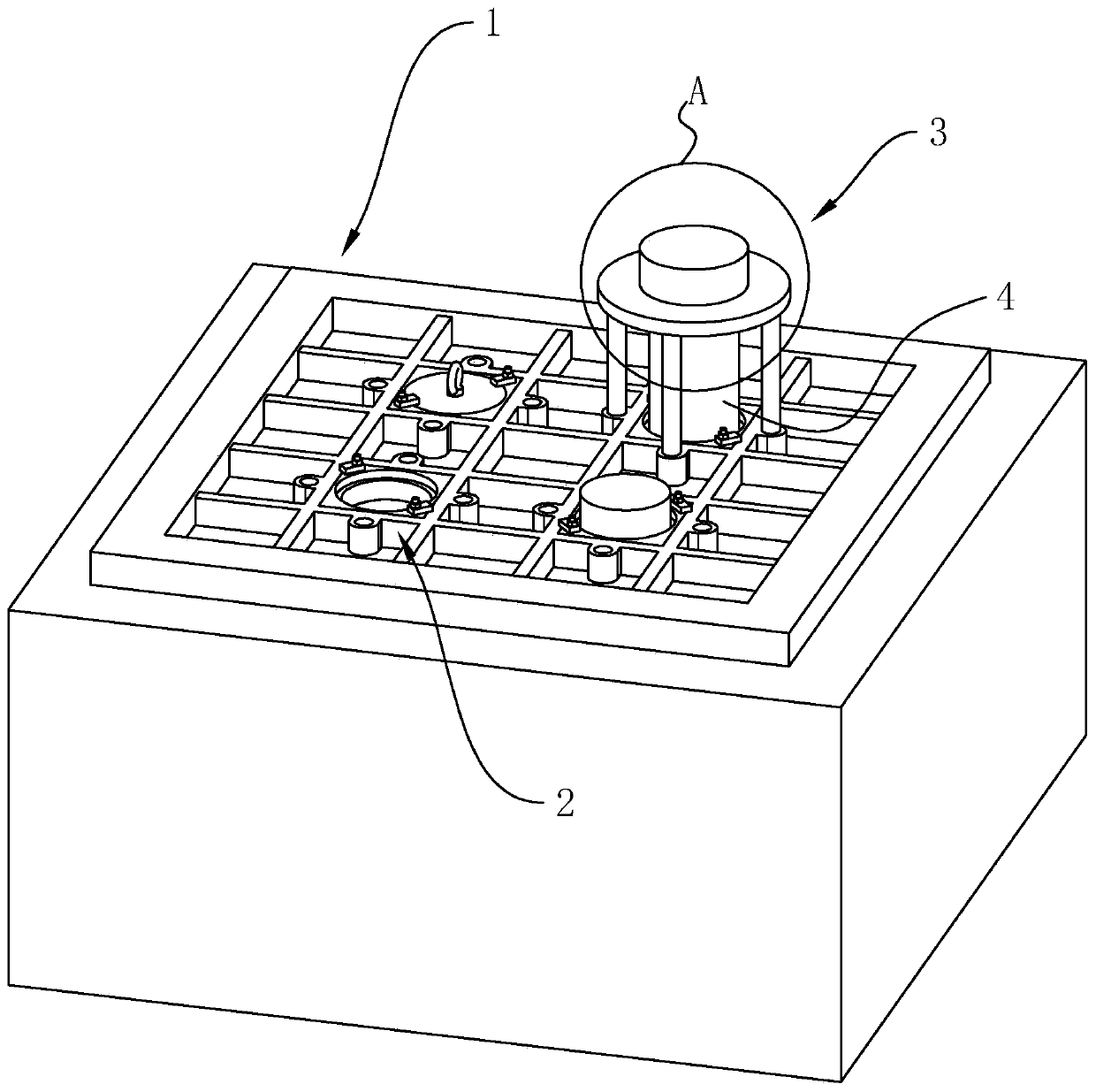

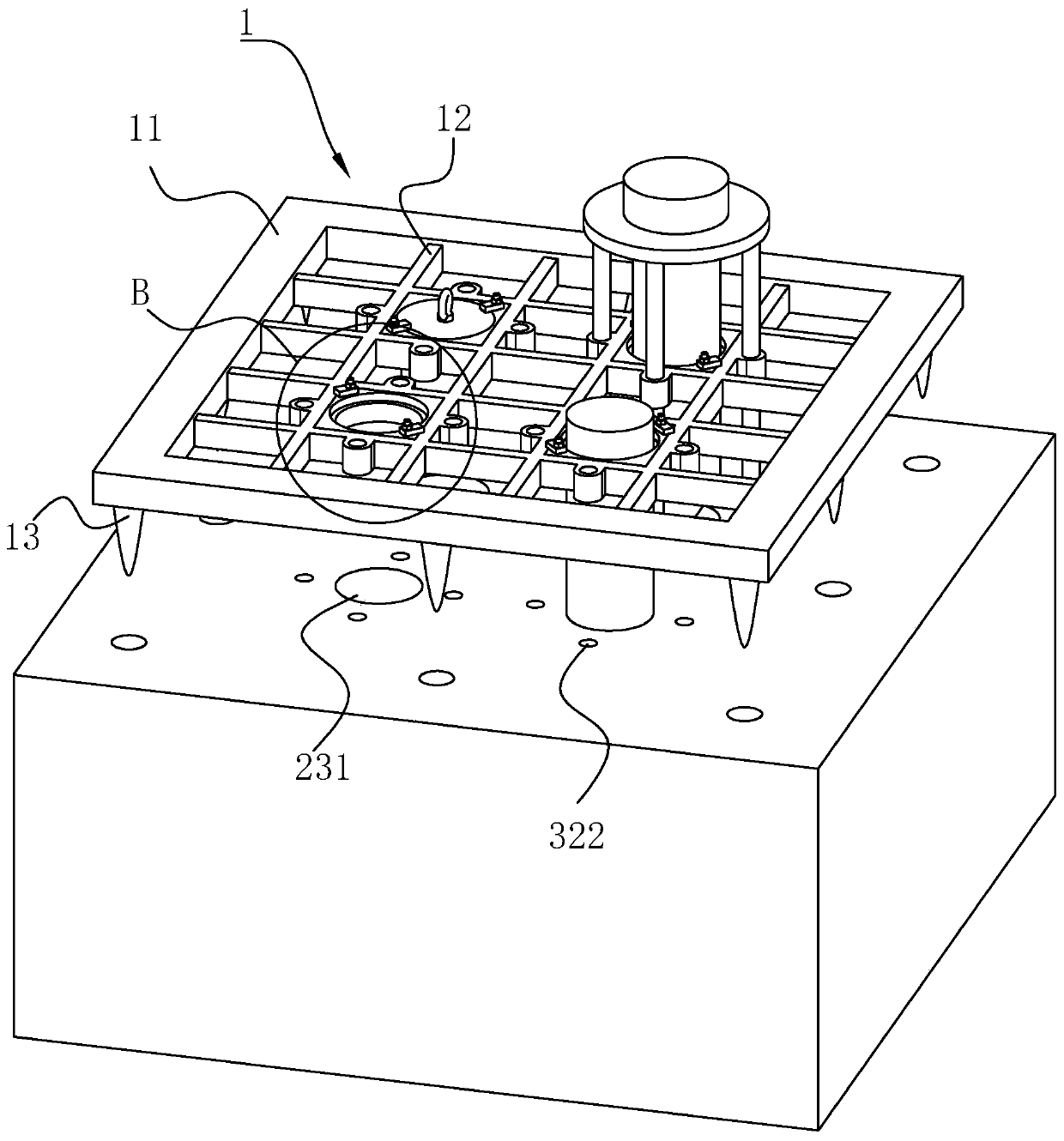

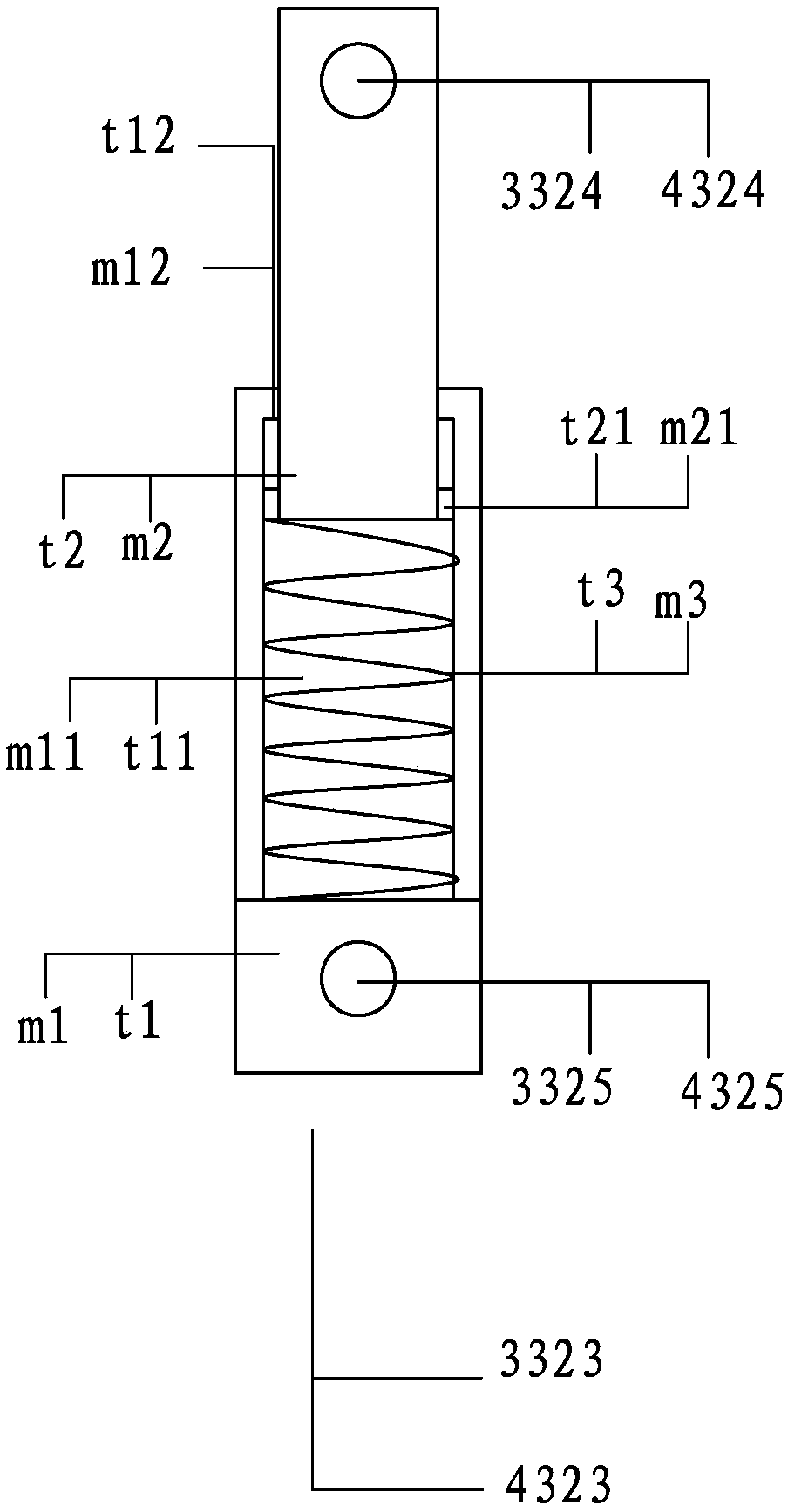

Pipe forming die

InactiveCN107335701AImprove bending efficiencyAvoid cracks or even breakageShaping toolsMaterials scienceSteel tube

The invention discloses a pipe fitting forming die, comprising an upper die and a lower die, and is characterized in that: the upper die is provided with a lower die, two sides of the lower die are provided with movable lower dies, and a guide shaft is arranged on the lower die , the movable lower die is provided with a pin shaft, the lower die and the movable lower die are provided with a lower die plate, a spring is arranged between the lower die and the lower die plate, and a spring is arranged between the movable lower die and the lower die plate and the clamping plate, the clamping plate is provided with a guide plate, and a roller is arranged between the spring and the movable lower die; the present invention has a simple structure, and the bending efficiency is fast after the steel pipe enters and is completed, and the problem of cracking or even breaking of the steel pipe is prevented; The present invention is convenient and safe to use, will not accidentally injure staff, is safe and reliable, and can realize multi-angle bending.

Owner:芜湖通全科技有限公司

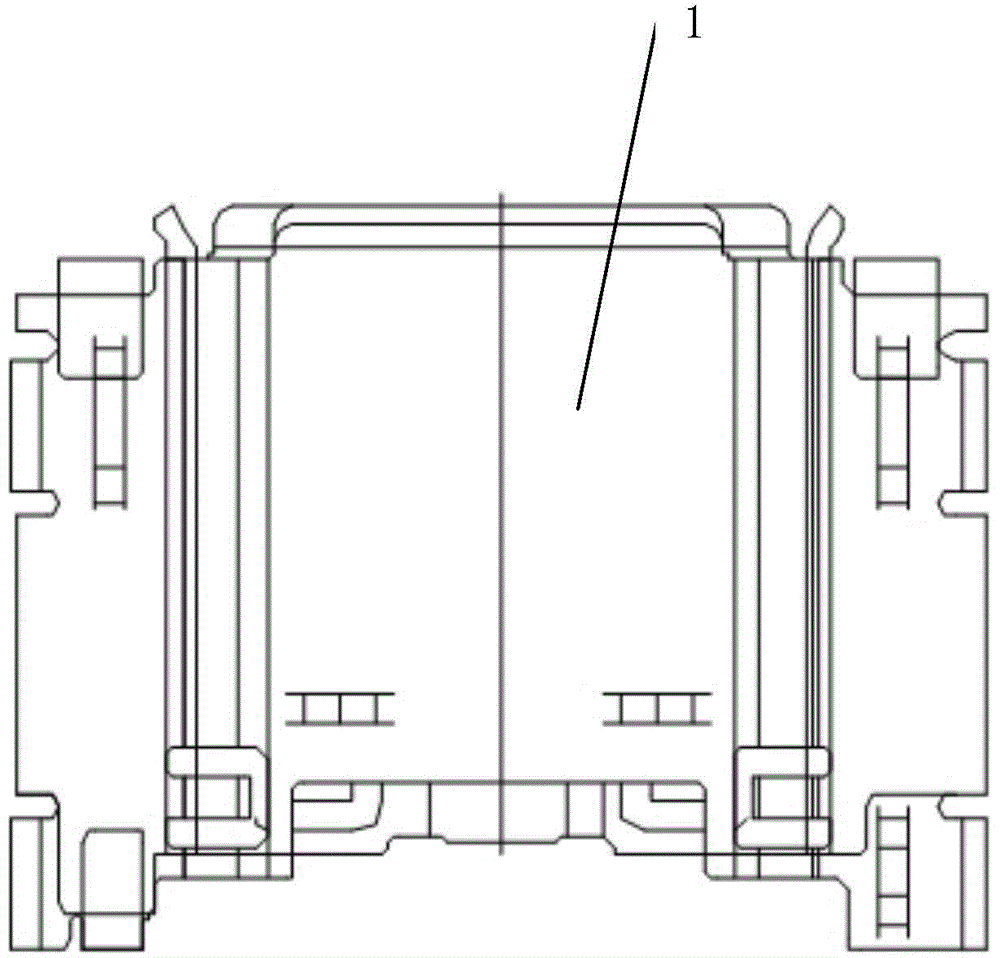

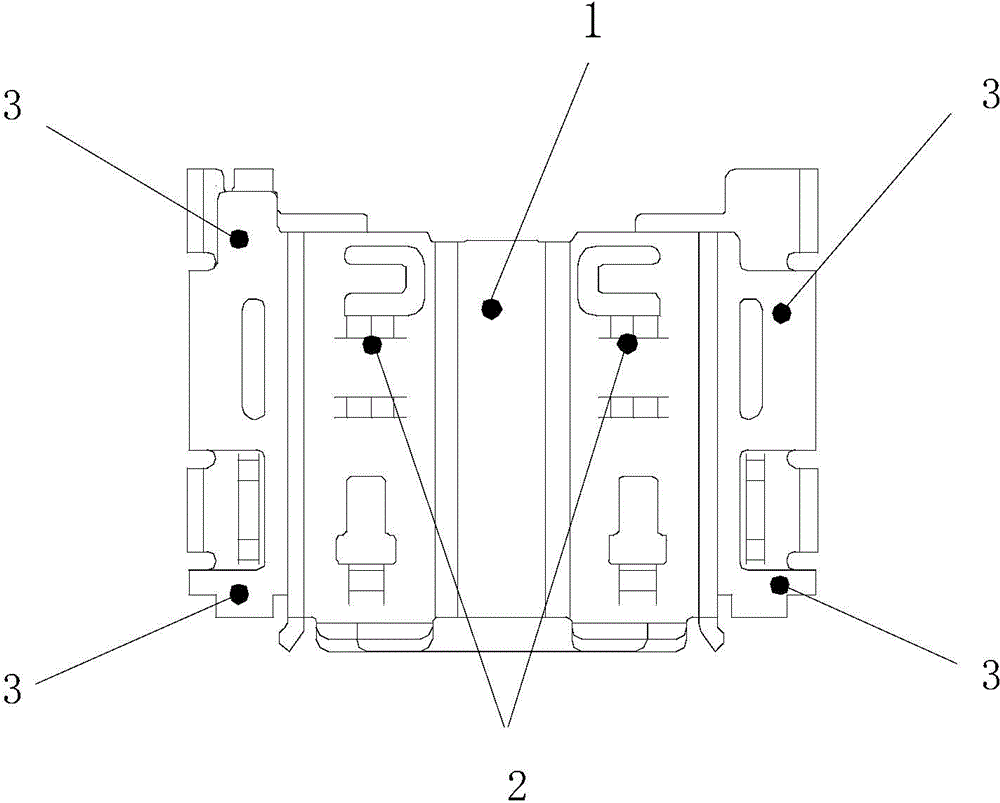

Insertion and connection terminal box and high-precision manufacturing method thereof

The invention provides an insertion and connection terminal box and a high-precision manufacturing method of the insertion and connection terminal box to solve the problem that according to an existing terminal box production process, the coplanarity precision requirement is difficult to meet and the widths of protruding ribs are difficult to control. The insertion and connection terminal box comprises a box body which is of a vertically overlapped structure, wherein one lateral side of the box body is a bent edge, the other lateral side of the box body is an overlapping edge, the box body is provided with two protruding rib structures which are horizontally symmetrical, the left side of the box body and the right side of the box body are provided with a plurality of coplanarity measurement points, and the coplanarity of the box body is controlled within 0.035. The high-precision manufacturing method of the insertion and connection terminal box includes the steps of firstly, punching positioning holes; secondly, shearing a knife edge on one side of each protruding rib, and cutting off, supplementing and correcting the knife edge; thirdly, conducting the band tearing and folding process; fourthly, conducting the 45-degree pre-folding process; fifthly, conducting the 90-degree pre-folding process; sixthly, conducting the 135-degree pre-folding process; seventhly, conducting the flattening forming process; eighthly, conducting the adjusting process, wherein the fourth step, the fifth step and the sixth step are executed step by step. According to the insertion and connection terminal box and the high-precision manufacturing method, by improving a punching die and adding the supplementing, correcting and cutting-off process and the multi-stage pre-folding process, product accuracy and product quality are improved.

Owner:青岛钜祥精密模具有限公司

Washing machine and method for controlling detergent drawer thereof

ActiveCN107190477BImprove user experienceReduce failure rateOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention discloses a washing machine and a detergent bucket control method thereof, wherein the washing machine comprises a bucket bracket (1), and a detergent bucket (2) capable of sliding pumping is installed in a sliding slot of the bucket bracket, along the detergent The sliding direction of the drawer is such that a magnet is attached to the front end and / or the rear end of the detergent bucket, and an electromagnet (5) is fixedly mounted on the bucket bracket. In the washing machine of the present invention, in the energized state, the electromagnet can realize the automatic opening or closing of the detergent bucket by the magnetic force between the magnet and the magnet installed at the front end and / or the rear end of the detergent bucket, thereby effectively preventing the detergent from being effectively prevented. The bucket opening and closing structure cracks or even breaks due to mechanical fatigue after repeated use, thereby reducing the probability that the detergent bucket will fail due to failure to open or close, and improving the user's experience with the washing machine.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Anti-winding electric wire cable

ActiveCN112820460APromote recoveryCracks or even breaks are not easy to appearFlexible cablesFlexible conductorsEngineeringStructural engineering

The invention discloses an anti-winding electric wire cable, the cable comprises a sheath and a cable core arranged in the sheath, a plurality of anti-winding mechanisms are arranged between the sheath and the cable core, the plurality of anti-winding mechanisms are arranged along the axial linear array of the cable, and the anti-winding mechanisms are arranged in the axial linear array of the cable. Each anti-winding mechanism comprises a plurality of telescopic mechanisms which are annularly arrayed in the circumferential direction of the cable core, each telescopic mechanism comprises two fixing seats, the two fixing seats are arranged side by side in the axial direction of the cable, and the two fixing seats are fixedly connected to the inner wall of the sheath; a connecting rod mechanism is arranged between the two fixed seats, the connecting rod mechanism comprises four connecting rods, the four connecting rods are rotationally connected to form a rhombus structure, and the rhombus structure is provided with four end points, namely an end point a, an end point b, an end point c and an end point d. The cable has the advantages of being capable of preventing winding and bending and preventing the cable core from being broken.

Owner:河北亿正线缆有限公司

Automatic practical rotary cutting device

ActiveCN108673652APrecise positioningAvoid scratchesProfiling/shaping machinesVeneer manufactureMotor drive

The invention provides an automatic practical rotary cutting device. According to the rotary cutting device, before the rotary cutting device starts rotary cutting work, a first lifting driving deviceslides in the direction far away from a second clamping part along a first horizontal guide rail, a first lower telescopic supporting rod and a second lower telescopic supporting rod slide to be in contact with a log in a top abutting mode, the log is supported to be in contact with an upper driving wheel single body in a top abutting mode, a first advancing and retreating motor drives a first rotating shaft to move in the direction away from a second clamping part, a first lifting frame moves to the position where the height of a first cutting knife corresponds to the circle center of the log, working personnel rotate a first operation handle for adjustment, then a first clamping arm clamps the log, a controller controls driving of a first lifting motor, so that the pressure of a first main base plate to the first lifting frame before the round log is clamped is equal to the pressure after the round log is clamped, then the first lifting driving device slides in the direction close to the second clamping part along the first horizontal guide rail, the first rotating shaft moves in the direction close to the second clamping part, and then the first cutting knife and the log are aligned automatically.

Owner:漳州市炯辉机械有限公司

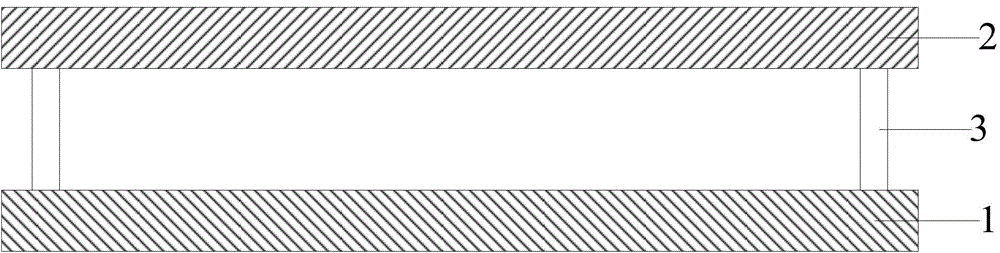

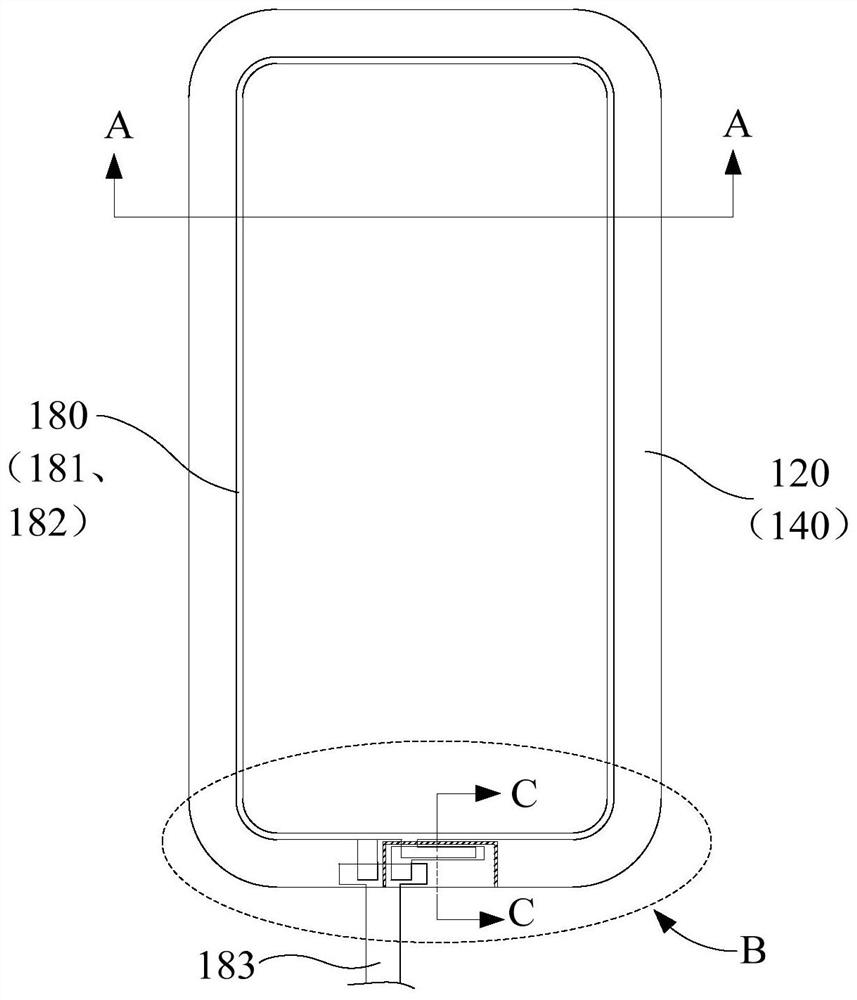

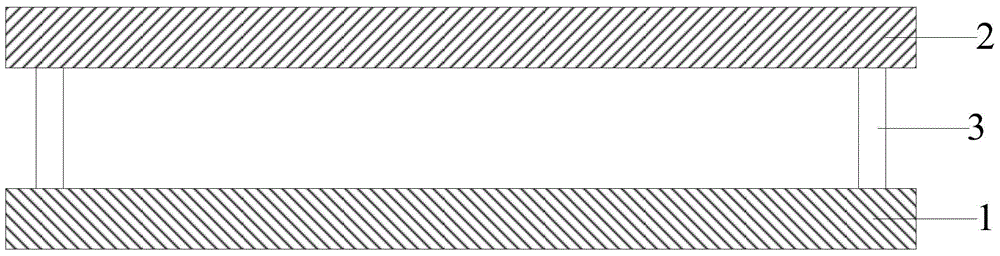

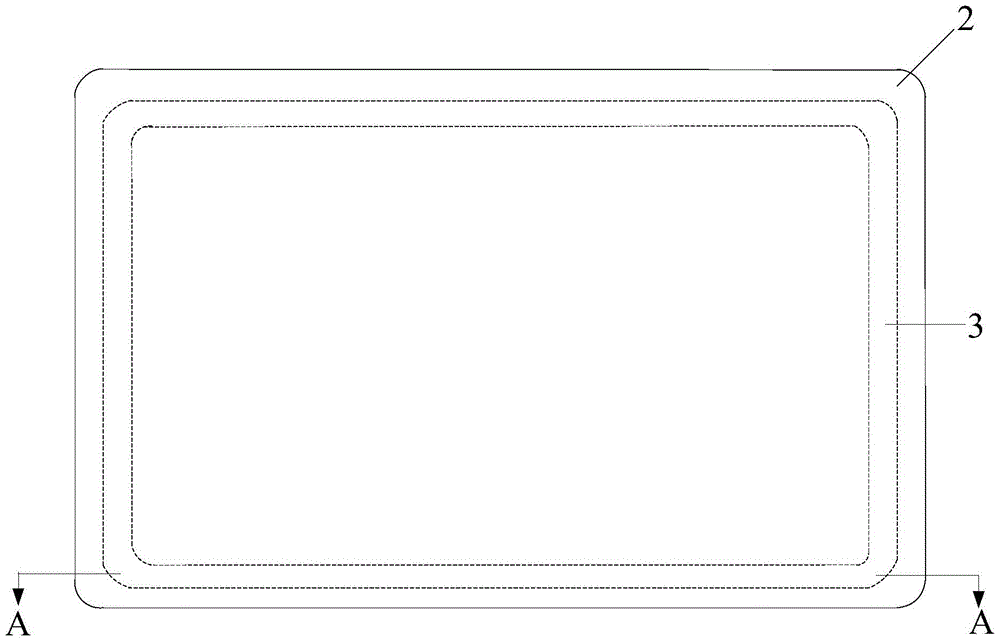

Electronic equipment, electrochromic module and manufacturing method of electrochromic module

PendingCN114637149AImprove connection reliabilityReliable conductionNon-linear opticsElectrochromismMechanical engineering

The invention provides electronic equipment, an electrochromic module and a manufacturing method of the electrochromic module. The electrochromic module comprises a first assembly plate and a second assembly plate which are oppositely arranged; the first assembly plate and the second assembly plate are respectively provided with a first metal wire and a second metal wire; the first assembly plate is provided with a first wire leading-out end connected with the first metal wire and a second wire leading-out end which is adjacent to the first metal wire and is arranged at an interval with the first metal wire, and the second assembly plate is provided with a wire connecting end connected with the second metal wire; the wiring connecting end is electrically connected with the second wiring leading-out end in a conducting manner; and a reinforcing layer is arranged in a partial region of the wiring connecting end. According to the electrochromic module, the reinforcing layer is arranged on the area where the wiring connecting end is connected with the second metal wiring, so that the connection reliability of the wiring connecting end and the second metal wiring can be improved, the situation of cracks and even breakage is avoided, and then reliable conduction of the metal wiring on the two sides is guaranteed, and electrostatic breakdown is prevented.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A kind of laser sintering equipment and sintering method

ActiveCN104466033BReduce stressReduce temperature differenceAdditive manufacturing apparatusSolid-state devicesOptoelectronicsLaser beams

The invention provides a laser sintering device and a sintering method. The laser sintering equipment includes: a first laser head, used to output a laser with a first power; a second laser head, used to output a laser with a second power; a driving device, used to drive the first laser head and the second laser head to move , so that the first laser head and the second laser head respectively heat the same area on the material to be sintered. The present invention utilizes two laser heads to heat the material to be sintered arranged on the device to be sintered, so that the two laser heads respectively heat a certain region of the material to be sintered to be heated respectively, so that the material to be sintered before laser sintering Preheating, or annealing the material to be sintered after laser sintering, so as to reduce the temperature difference before laser sintering compared with laser sintering or reduce the temperature drop rate after laser sintering, so as to reduce the stress of the substrate of the material to be sintered , to avoid cracks or even breakage caused by shrinkage stress.

Owner:BOE TECH GRP CO LTD +1

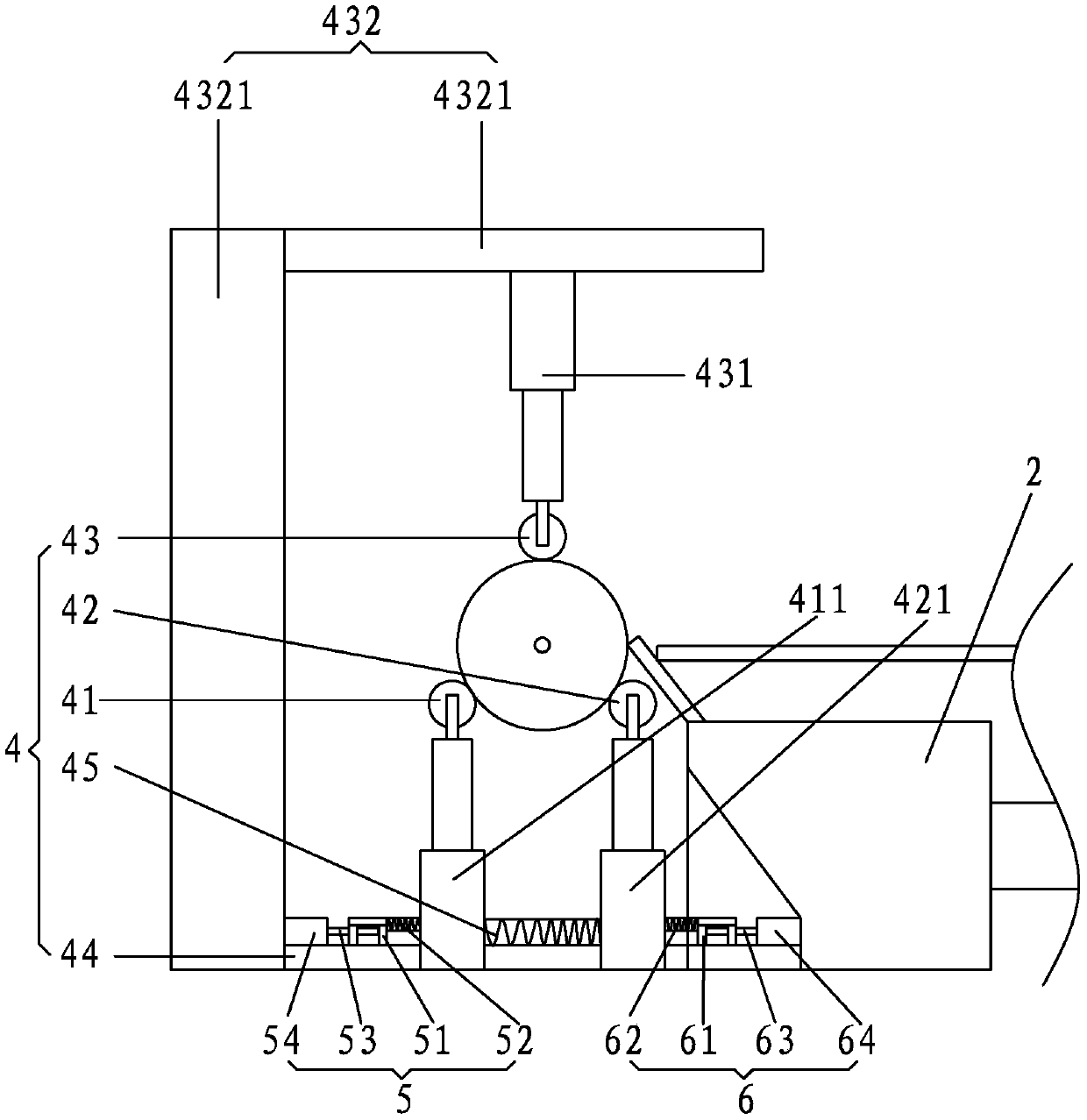

Intelligent accurate rotary-cut equipment

ActiveCN108687912AAvoid uneven forcePrevent deviationVeneer manufactureElectric machineryWheel drive

The invention provides intelligent accurate rotary-cut equipment. In the rotary-cut process, a first lifting driving device drives a first lifting frame to ascend and descend along a first guiding frame till the center of a first positioning cutting knife and the center of a round log are roughly at the same height; a user operates a first operating handle to push a first sleeve body to move alonga thread towards the round log; the first sleeve body applies the inward pressure to first positioning arms through first jacking sleeves, the first positioning arms conduct clamping through first jacking hand grabs, and finally the round log is clamped in an all-dimensional mode through all the jacking hand grabs of the three positioning arms; a first advance and retreat motor drives a first advance and retreat worm wheel to rotate through a first advance and retreat worm; the first advance and retreat worm wheel drives a first shaft body to slide towards the round log through a first advance and retreat screw; and a first blade makes contact with the round log in a jacking mode to conduct rotary-cut on the round log to form a groove corresponding to a first conical head, grooves formedby rotary-cut of a first end cover partially automatically make contact in a jacking mode, and thus the effect of automatic centering is achieved.

Owner:漳州市炯辉机械有限公司

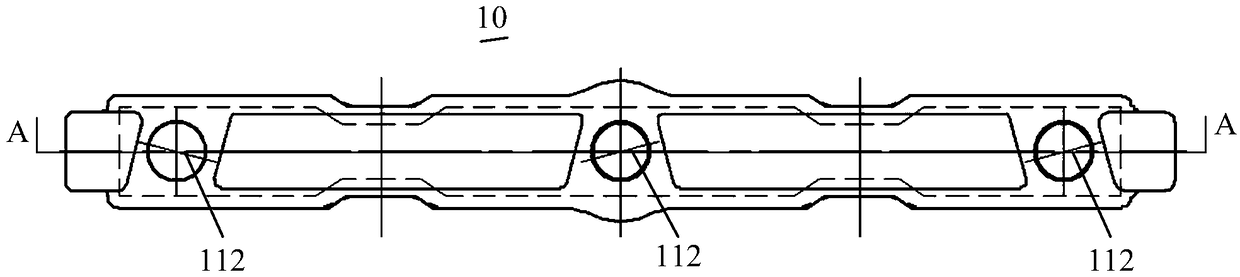

Press plate for scraper conveyor and production method thereof

ActiveCN106429211BStrength hasImprove wear resistanceConveyorsWear resistanceUltimate tensile strength

The invention discloses a pressing plate for a scraper conveyor. The pressing plate comprises an arbor, and a wear resisting layer wrapped on the outer surface of the arbor for forming a pressing plate body; a bonding layer is arranged between the arbor and the wear resisting layer; positioning through holes are spaced in the arbor; a transverse gap is formed in the wear resisting layer above the arbor; and the wear resisting layer parts on two sides of the transverse gap are upwards projected to form a limiting table. The arbor serves as a support skeleton of the pressing plate, so that the strength and the toughness of the pressing plate satisfy the working demands; the wear resisting layer serves as a main body of the pressing plate, so that the pressing plate has needed strength for normal work, meanwhile, the wear resistance is greatly improved, the weight is obviously lowered compared with metal, the weight of the pressing plate is reduced, the total weight of a scraper chain is reduced, the idle loss of the scrape conveyor is reduced, the energy saving target is realized, meanwhile, the phenomenon of crack or even rupture caused by residual stress of heat treatment is prevented, and the overall life is largely prolonged.

Owner:NINGXIA TIANDI BENNIU IND GRP

An engineering pipe pile foundation

The invention discloses an engineering pipe pile foundation, and belongs to the field of building construction. According to the technical scheme, the foundation comprises a fixed net, a fixed devicefixedly arranged in the fixed net, a prefabricated pile fixed into the fixed device and a stress device arranged on the prefabricated pile. The fixed net is composed of a frame and cross beams, the cross beams have the longitudinal cross beam and the transverse cross beam, the longitudinal cross beam and the transverse cross beam are crossed, the stress device comprises a stress cylinder arrangedat the upper end of the prefabricated pile in a sleeving manner and a ring fixed to the lower end of the stress cylinder, the inner ring of the ring is attached to the outer surface of the prefabricated pile, and multiple guide piles are evenly fixed to the lower surface of the ring. The problem that the pipe pile foundation is prone to knowing down is solved, and the effect of preventing the pipepile foundation from toppling and breaking is achieved.

Owner:YONGJIA ZHONGHONG CONSTR

An automatic precision rotary cutting machine

ActiveCN108673686BPrecise positioningEasy to holdProfiling/shaping machinesVeneer manufactureDrive wheelElectric machinery

The invention puts forwards an automatic precision rotary cutting machine. Before a rotary cutting device begins to perform rotary cutting, a first lifting driving device slides away from a second clamping part along a first horizontal guiding rail, a first lower telescopic supporting rod and a second lower telescopic supporting rod slide to make contact with a log in an abutting manner, the log is supported to abut against an upper driving wheel single body, a first advancing and retreating motor drives a first rotating shaft to move away from a second clamping part, a first lifting frame moves to the height, corresponding to the circle center of the log, of a first cutter, a worker rotates a first operating handle for adjustment, the first clamping arm clamps the log, a controller controls driving of a first lifting motor, the pressure applied by a first main base plate to the first lifting frame before the log is clamped is equal to the pressure after the log is clamped, the first lifting driving device slides towards the second clamping part along the first horizontal guiding rail, the first rotating shaft moves towards the second clamping part, and the first cutter is automatically aligned to the log.

Owner:漳州市炯辉机械有限公司

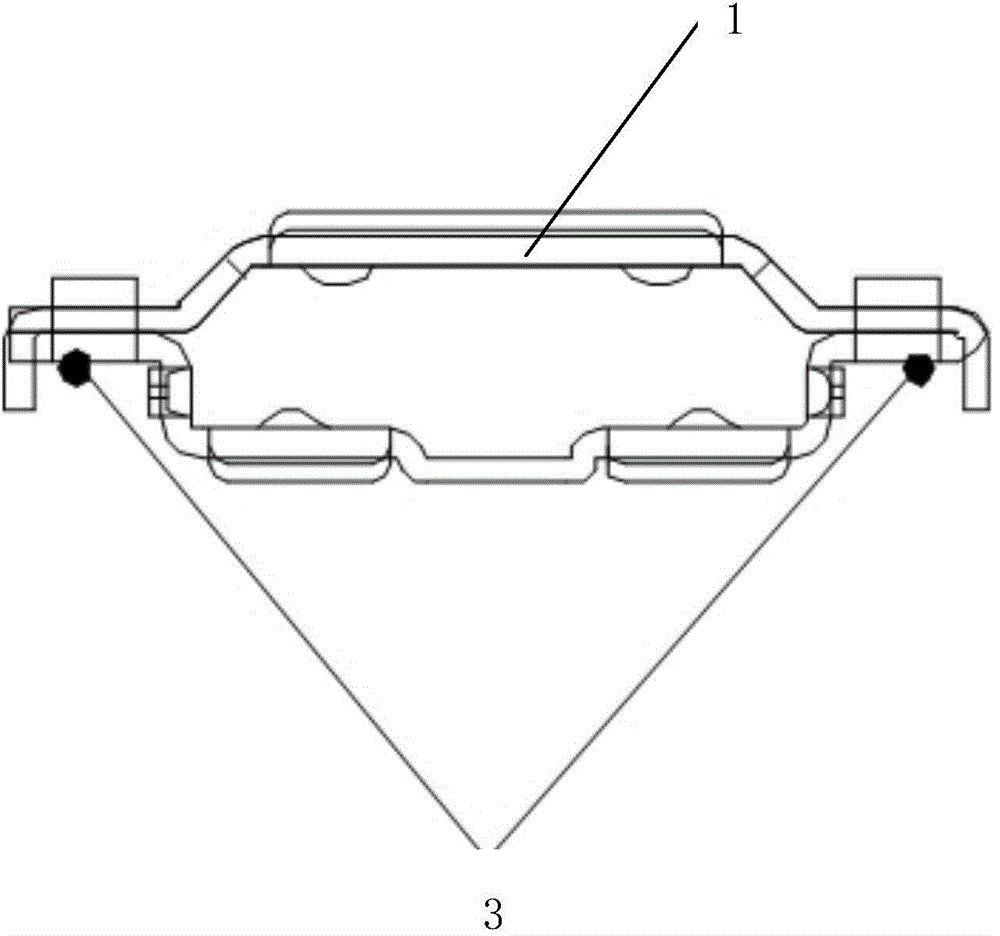

Assembly type bridge shock absorption device

PendingCN111764258AReduce shockAvoid cracks or even breakageBridge structural detailsShock avoidanceArchitectural engineering

The invention discloses an assembly type bridge shock absorption device, which comprises a bridge assembly and supporting assemblies, wherein the bridge assemblies are installed on the outer side of the upper portion of the supporting assembly, an assembly plate is installed at the joint of the bridge assembly and the supporting assembly, and two sealing plates are installed on the outer side of each supporting assembly. In the invention, the bridge assembly and the supporting assemblies work in a matched mode. When accidental impact force and geological disasters happen, a first buffer plate,a second buffer plate and a third buffer plate buffer a bridge body and a mounting column, impact of the accidental impact force and the geological disasters on the bridge body and the mounting column is reduced, and the phenomenon that the fabricated bridge cracks and even fractures is avoided. Through cooperative work of the supporting assemblies, first springs play a role in buffering the sidesurface of the mounting column, the impact force borne by the side surface of the mounting column is reduced, second springs are matched with buffer columns to play a role in further buffering the mounting column, and the shock absorption performance of the fabricated bridge is improved.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Radiant air conditioner indoor unit

ActiveCN106500174BImprove heat transfer efficiencyGuaranteed comfortLighting and heating apparatusSpace heating and ventilation detailsPlate heat exchangerEngineering

The invention relates to a radial type air conditioner indoor unit. The radial type air conditioner indoor unit comprises a shell, a micro-channel heat exchanger and a hoisting device. A containing space is formed in the shell in a limited manner. The micro-channel heat exchanger is arranged in the containing space and provided with an upper flow collecting pipe, a lower flow collecting pipe and multiple heat exchange pipes located between the upper flow collecting pipe and the lower flow collecting pipe. The hoisting device is configured in a manner that the micro-channel heat exchanger is hoisted onto the shell through the hoisting device, the upper portion of the micro-channel heat exchanger is fixed relative to the shell, and the lower portion of the micro-channel heat exchanger is movable relative to the position, in the vertical direction, of the shell. In this way, the lower portion of the micro-channel heat exchanger can be moved downwards or upwards in the vertical direction relative to the shell, so that the micro-channel heat exchanger is matched with the heat exchange pipes of the micro-channel heat exchanger in expansion and extension or contraction and shortening; the situation that the heat exchange pipes are compressed to be deformed or cracked and even ruptured at the welding positions is avoided, and thus use safety of the radial type air conditioner indoor unit is guaranteed; and appearance of the radial type air conditioner indoor unit can be more attractive.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Automatic high quality rotary cutting device

ActiveCN108687911AAvoid uneven forcePrevent deviationVeneer manufactureElectric machineryKnife blades

The invention relates to an automatic high quality rotary cutting device. In a rotary cutting process, a first lifting driving device drives a first lifting rack to lift along a first guiding frame till the center of a first positioning cutter knife and the center of a log are substantially located at a same height. A user operates a first operating handle to push a first sleeve main body to movetoward the direction of the log along a thread; the first sleeve main body applies an inward pressure to a first positioning arm through a first leaning sleeve; the first positioning arm clamps the log through a pair of first leaning tongs; and finally, the log is clamped all around by means of the leaning tongs of three positioning arms. A first advancing and retreating motor drives a first advancing and retreating worm wheel to rotate through a first advancing and retreating worm; the first advancing and retreating worm wheel drives a first shaft main body to slide toward the direction of the log through a first advancing and retreating screw; a first blade is in leaning contact with the log and cuts the log rotatably to form a groove corresponding to a first cone-shaped head to be in leaning contact with a groove formed by rotatably cutting a first end cover automatically, so that an effect of automatic centering is achieved.

Owner:漳州市炯辉机械有限公司

Drilling equipment with positioning function and used for new material plate production

InactiveCN112453480AAchieve positioningAccurate and convenient positioningDrilling/boring measurement devicesPositioning apparatusGear driveGear wheel

The invention discloses drilling equipment with a positioning function and used for new material plate production, and relates to the technical field of new material plate production devices. The drilling equipment comprises an operating floor, a vertically-arranged side plate is arranged on one side of the operating floor, a cross beam is arranged at the top of the side plate, a driving motor isarranged on the end part of the cross beam, and a drill bit is installed on the driving motor; a telescopic motor A is arranged on the inner side of the side plate, and a baffle is arranged on the endpart of the telescopic motor A; and a kidney-shaped groove is formed in one side face of the baffle, a transmission gear and a driven gear are correspondingly arranged at the two ends of the kidney-shaped groove, a chain is in transmission connection between the transmission gear and the driven gear, a stop rod is arranged on the chain, and the transmission gear is connected with a transmission motor. By arranging the baffle and the stop rod, a drilled plate is positioned, and positioning and drilling are conveniently and accurately carried out; and meanwhile, through the mobility of the baffle and the stop rod, the drilling position of the plate is adjusted according to actual requirements.

Owner:广州雏鸟信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com