Insertion and connection terminal box and high-precision manufacturing method thereof

A manufacturing method and plug-in terminal technology, applied in the field of plug-in terminal box and its high-precision manufacturing, can solve problems such as affecting product accuracy, difficulty in control, limitation, etc., to improve the accuracy level, avoid cracks or even breakage, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

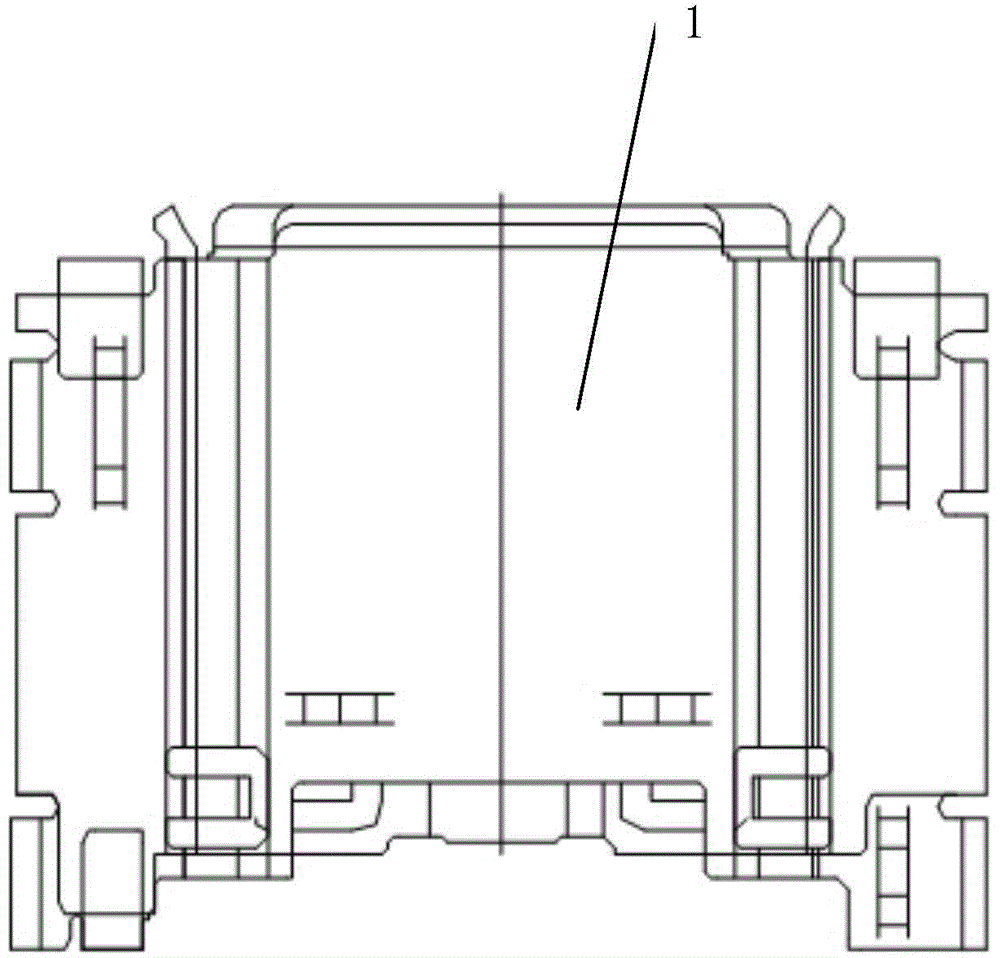

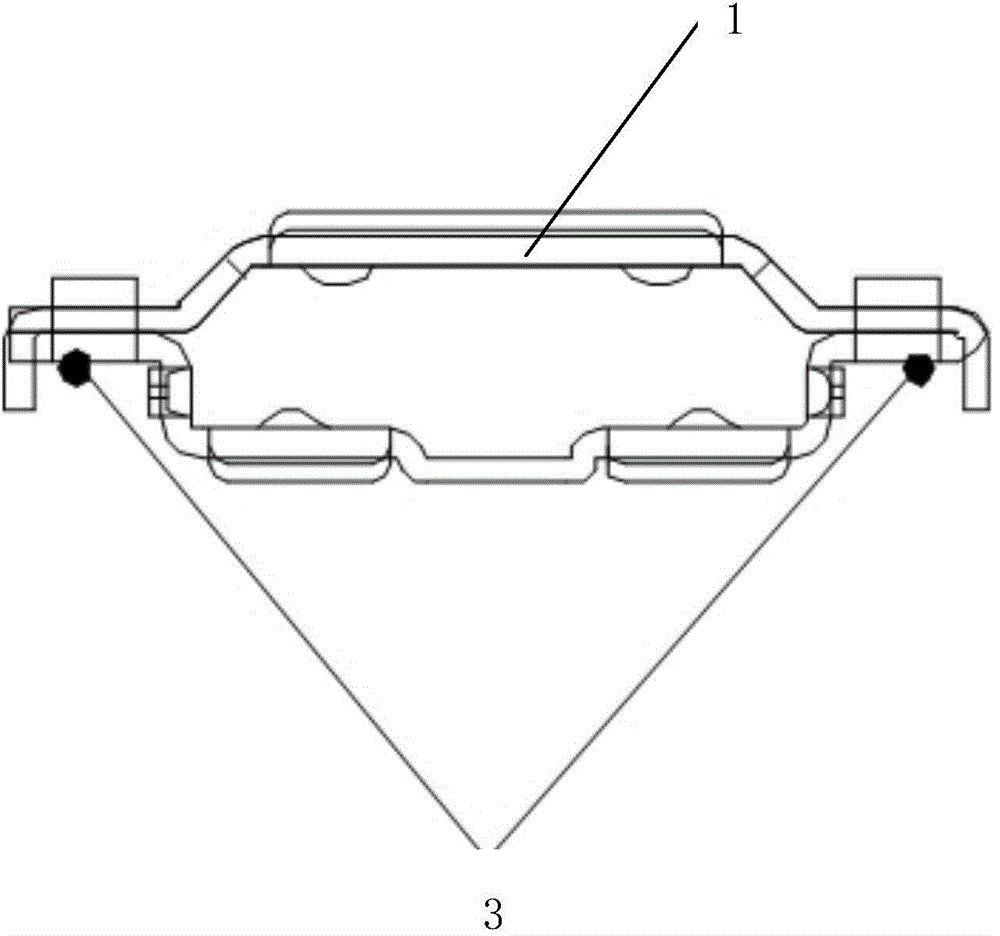

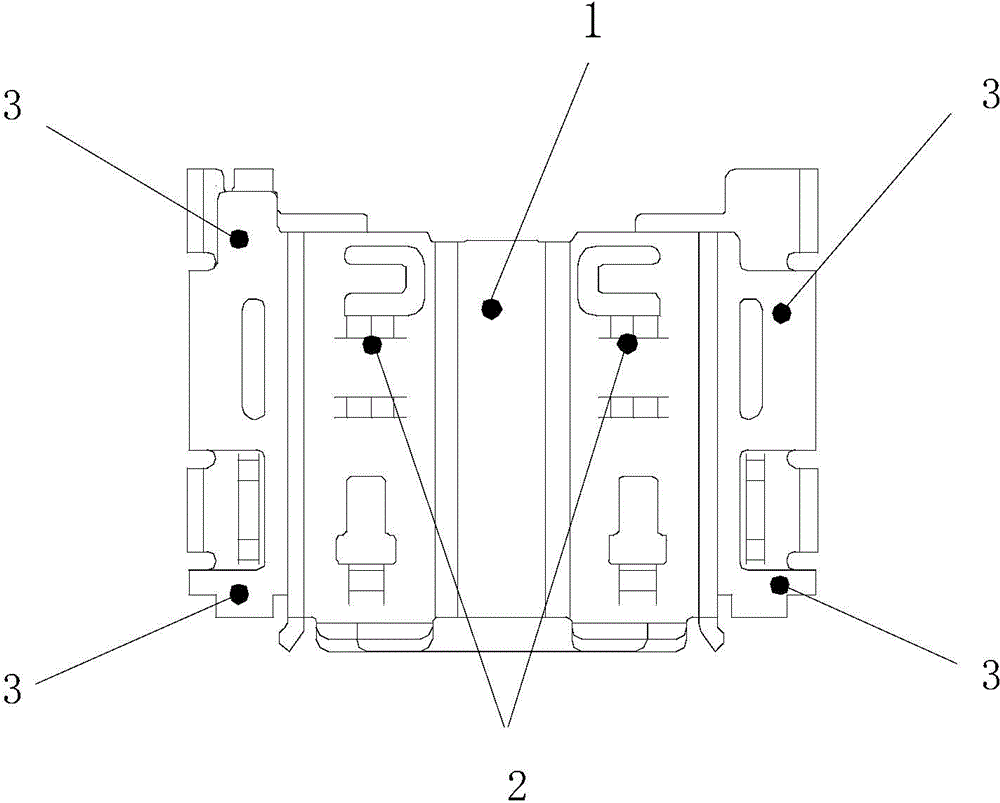

[0031] Such as figure 1 , 2 As shown in and 3, the plug-in terminal box includes a box body 1 stacked up and down, and the box body 1 is a stainless steel shell.

[0032] One side of the box body 1 is a bent edge, and the other side is a coincident edge. The box body 1 has two left-right symmetrical convex rib structures 2 . A total of 4 coplanarity measurement points 3 are set on the left and right sides of the box body 1, and the drop between the highest point and the lowest point of the 4 coplanarity measurement points 3 is controlled within 0.035mm (ie, coplanarity).

[0033] High-precision manufacturing method for a plug-in terminal box, comprising the following production steps:

[0034] (1) After the material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com