High-precision excircle grinding tool for shaft parts

A technology for cylindrical grinding and shaft parts, which is applied in the field of high-precision cylindrical grinding tools for shaft parts, can solve the problems of unreasonable guidance, insufficient rigidity, uneven deformation of grinding tools, etc. Leading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

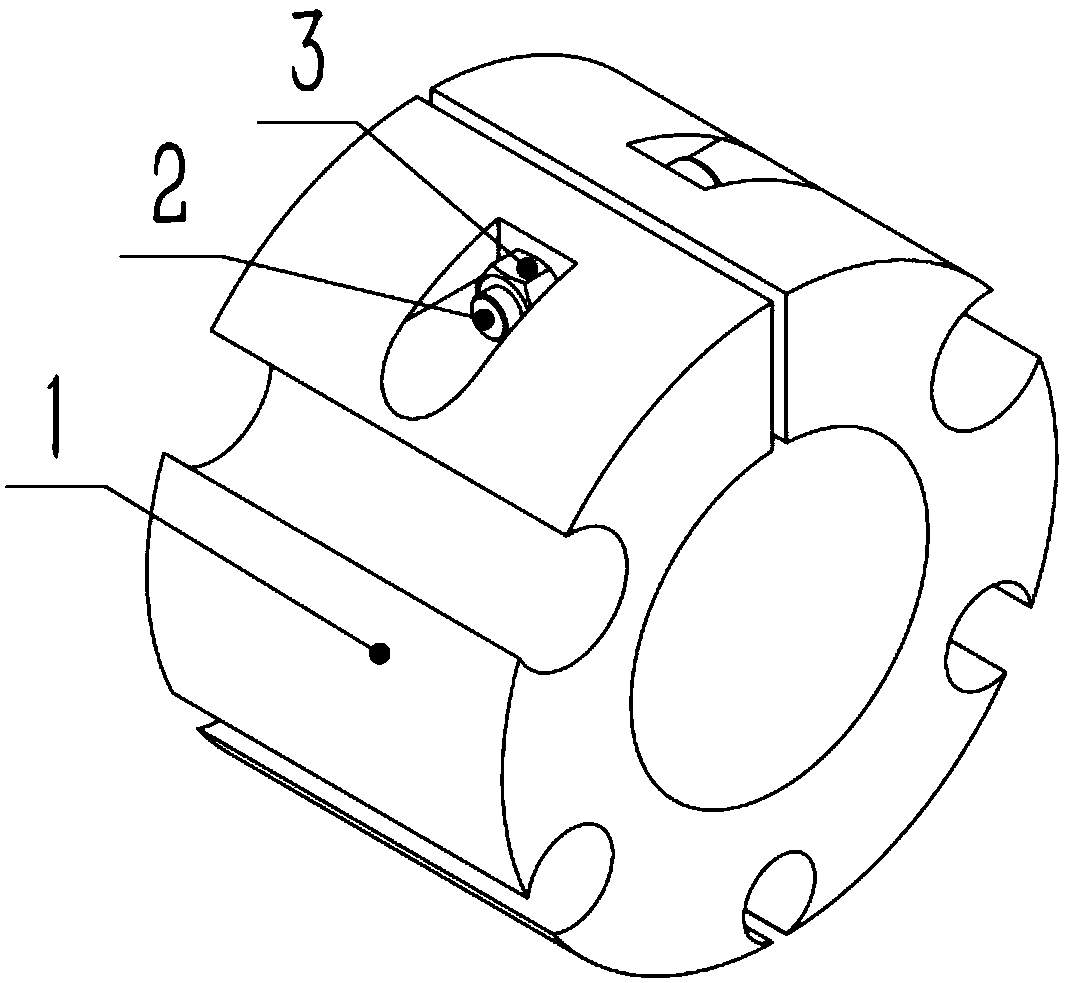

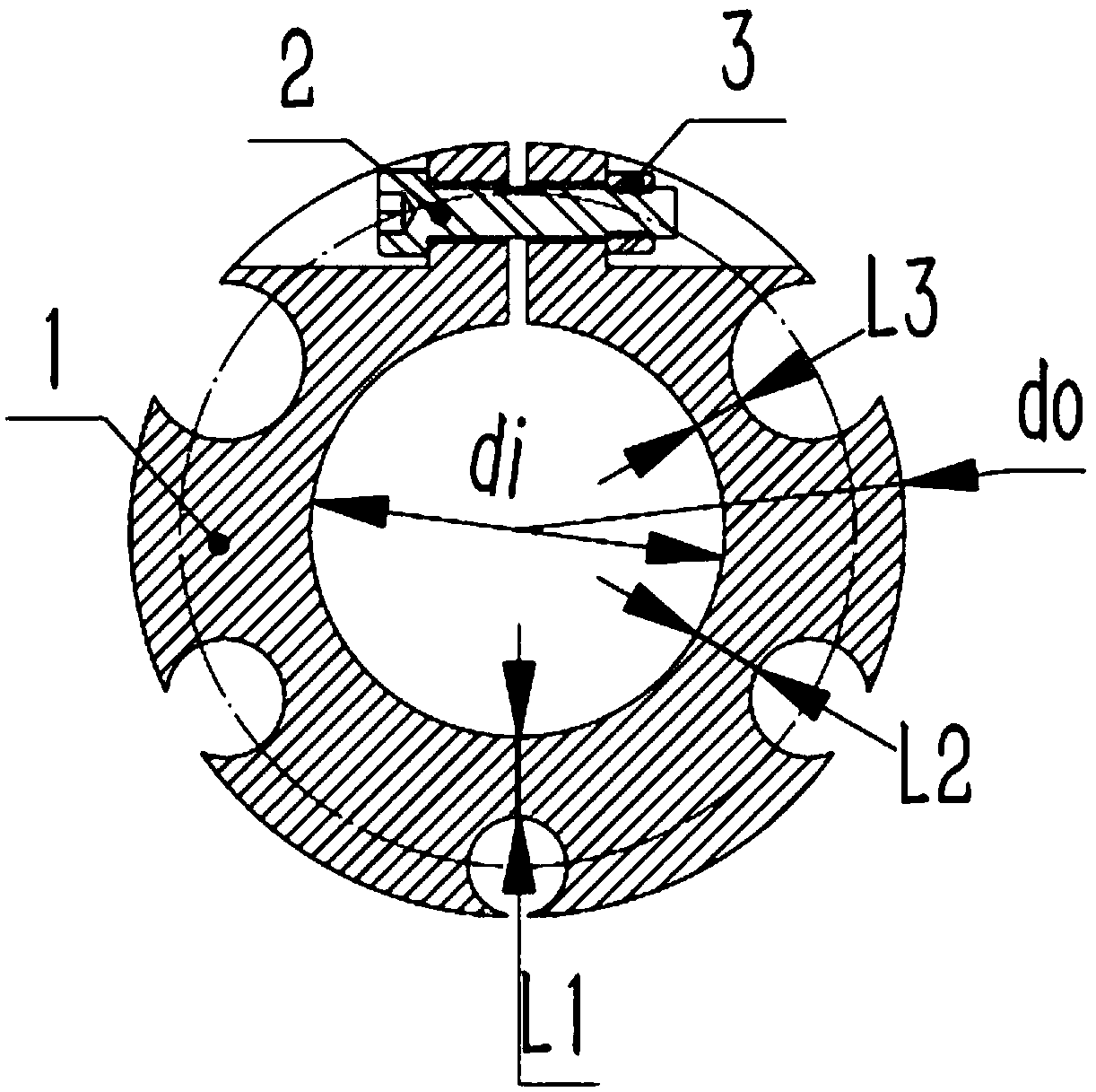

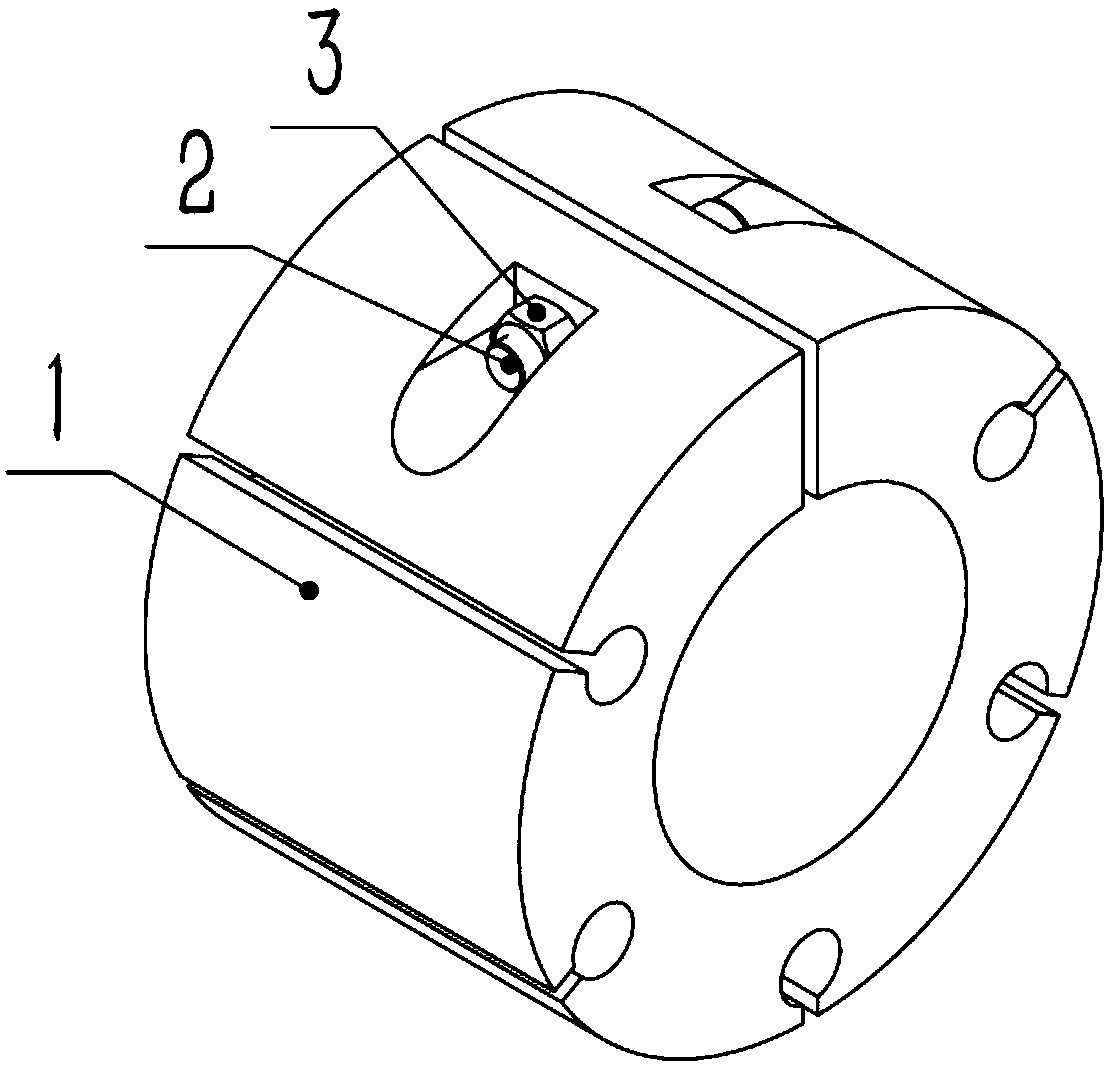

Image

Examples

Embodiment 1

[0043] Embodiment 1: The grinding tool body adopts gray cast iron, and the outer circle size is Grinding the quenched bearing steel, the steps are as follows:

[0044] Step 1: Use the grinding mandrel to trim the inner hole of the grinding tool to ensure that all the inner holes are ground;

[0045] Step 2: Clean and wipe the grinding tool, and adjust the inner hole of the grinding tool to the size of the outer circle to be ground;

[0046] Step 3: Choose a suitable abrasive and apply it evenly on the outer circle of the part;

[0047]Step 4: During work, by adjusting the pressing force of the adjusting bolt 2, the grinding and cutting force and the dimensional tolerance of the ground workpiece are controlled to achieve high-precision grinding of the ground part.

[0048] During the grinding process, the grinding liquid must be added at any time, and it should be added frequently and less, and the pressing force of the adjusting screw should be adjusted at any time accordin...

Embodiment 2

[0050] Embodiment 2: The grinding tool body is made of nodular cast iron. The outer circle size is The quenched bearing steel is ground, and its grinding step is identical with embodiment 1, detects the outer circle degree of parts after grinding, as Figure 8 As shown, the outer roundness is less than 0.2um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com