Three-face over-constrained scissor-type lifting mechanism

A lifting mechanism and over-constraint technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of increasing structural instability, poor structural rigidity, and large force changes of the mechanism, so as to increase the maximum operating height, increase rigidity and The effect of stability and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention provides a three-sided over-constrained scissor lift mechanism. The structure, principle and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

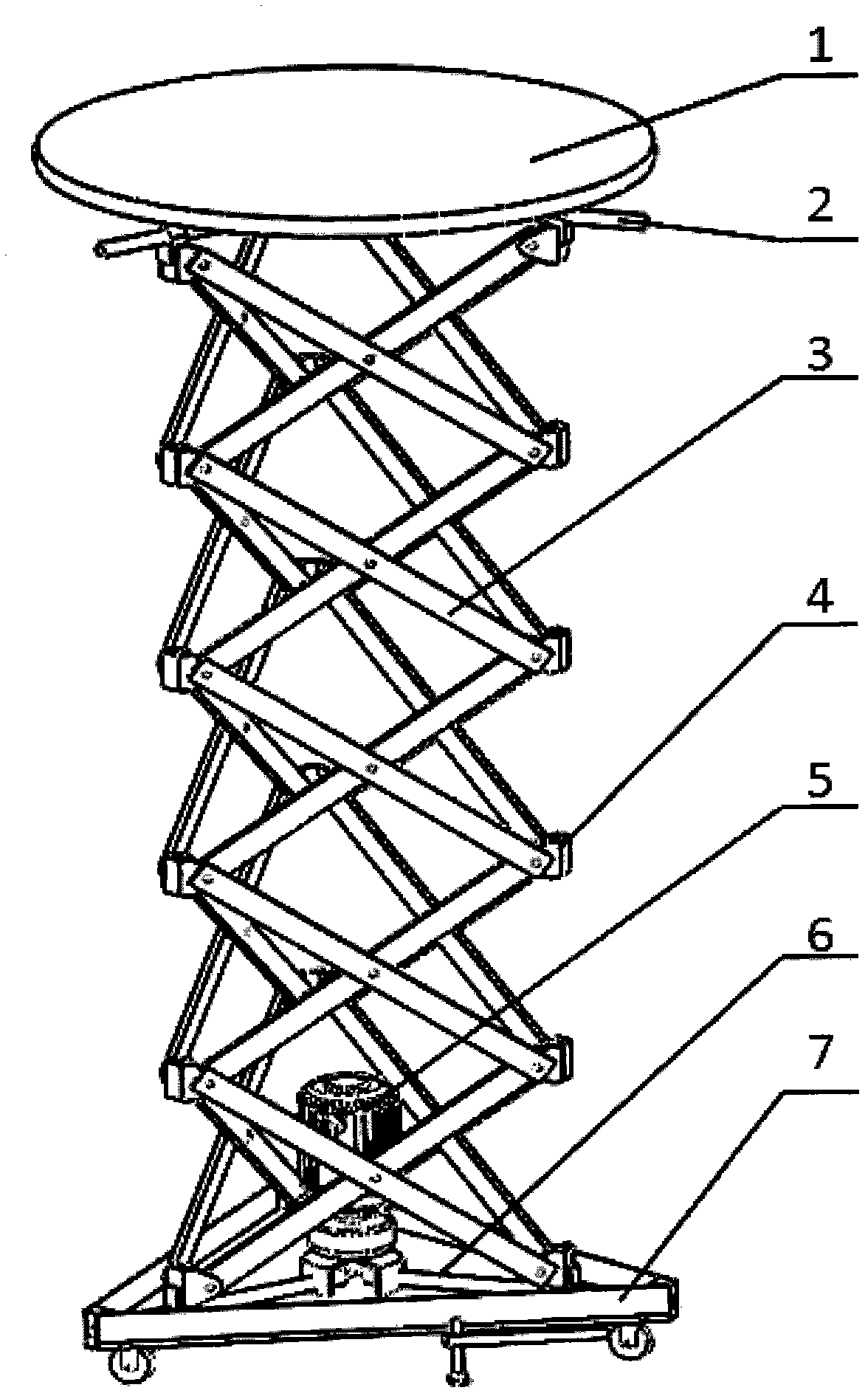

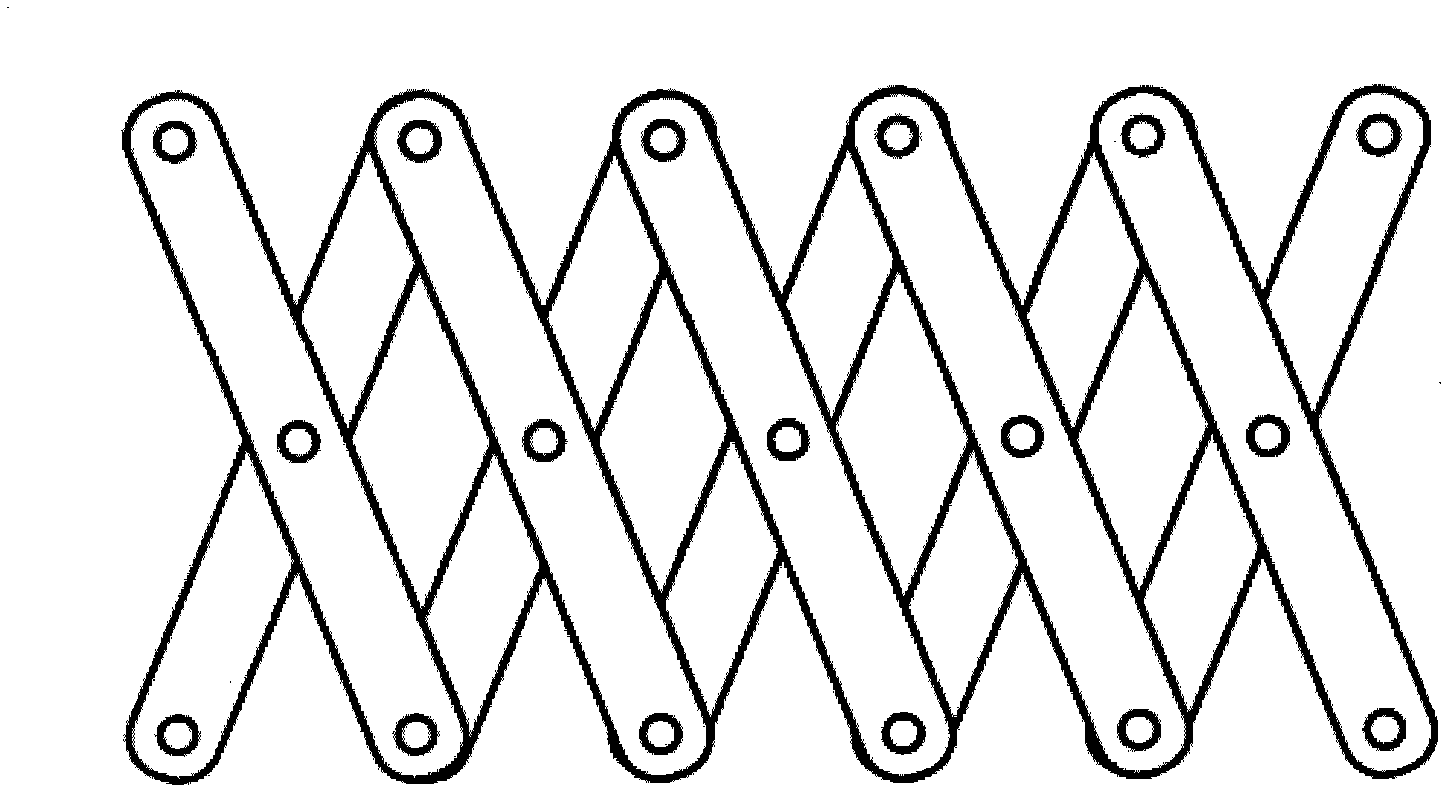

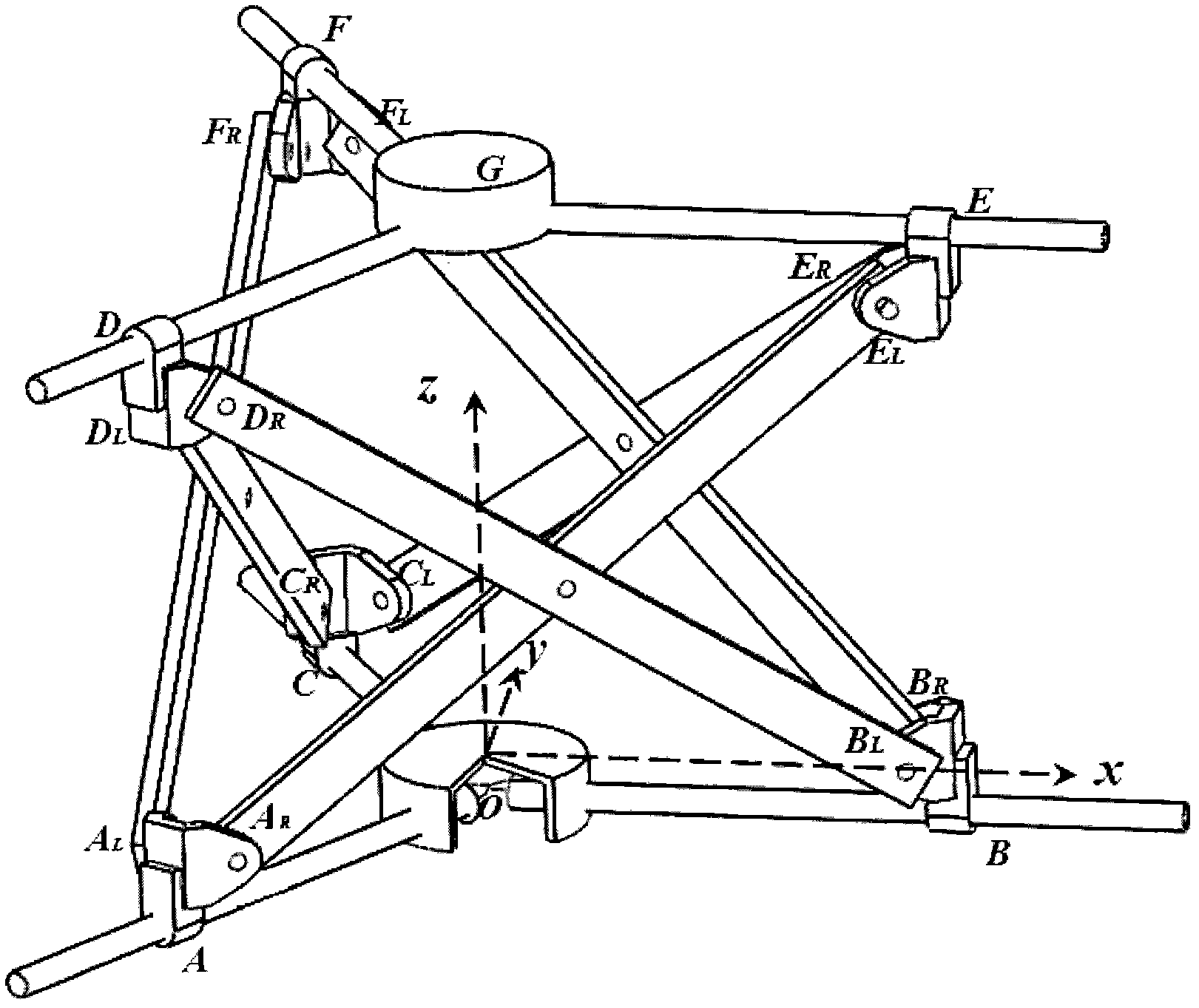

[0020] Such as figure 1 and figure 2 As shown, the structure of the lifting mechanism includes a supporting platform 1 , an upper guide rail 2 , a scissor truss 3 , a connecting piece 4 , a lower guide rail 6 , and a base 7 . The scissor truss 3 is an expandable mechanism composed of a plurality of scissor units, a pair of connecting rods of each scissor unit is connected by a rotating pair, and each pair of connecting rods can only rotate around the The axis of the plane where the connecting rod is located is relatively rotated, and at the same time, both ends of the connecting rod are connected to other scissor-type units through a rotating pair parallel to the axis of the middle rotating pair; the three-sided over-constraine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com