Vertical rotary workbench of numerical control machine tool

A vertical rotary and CNC machine tool technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems that the processing accuracy of the workpiece cannot be guaranteed, the positioning of the rotary table is affected, and the positioning of the workpiece is not accurate enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

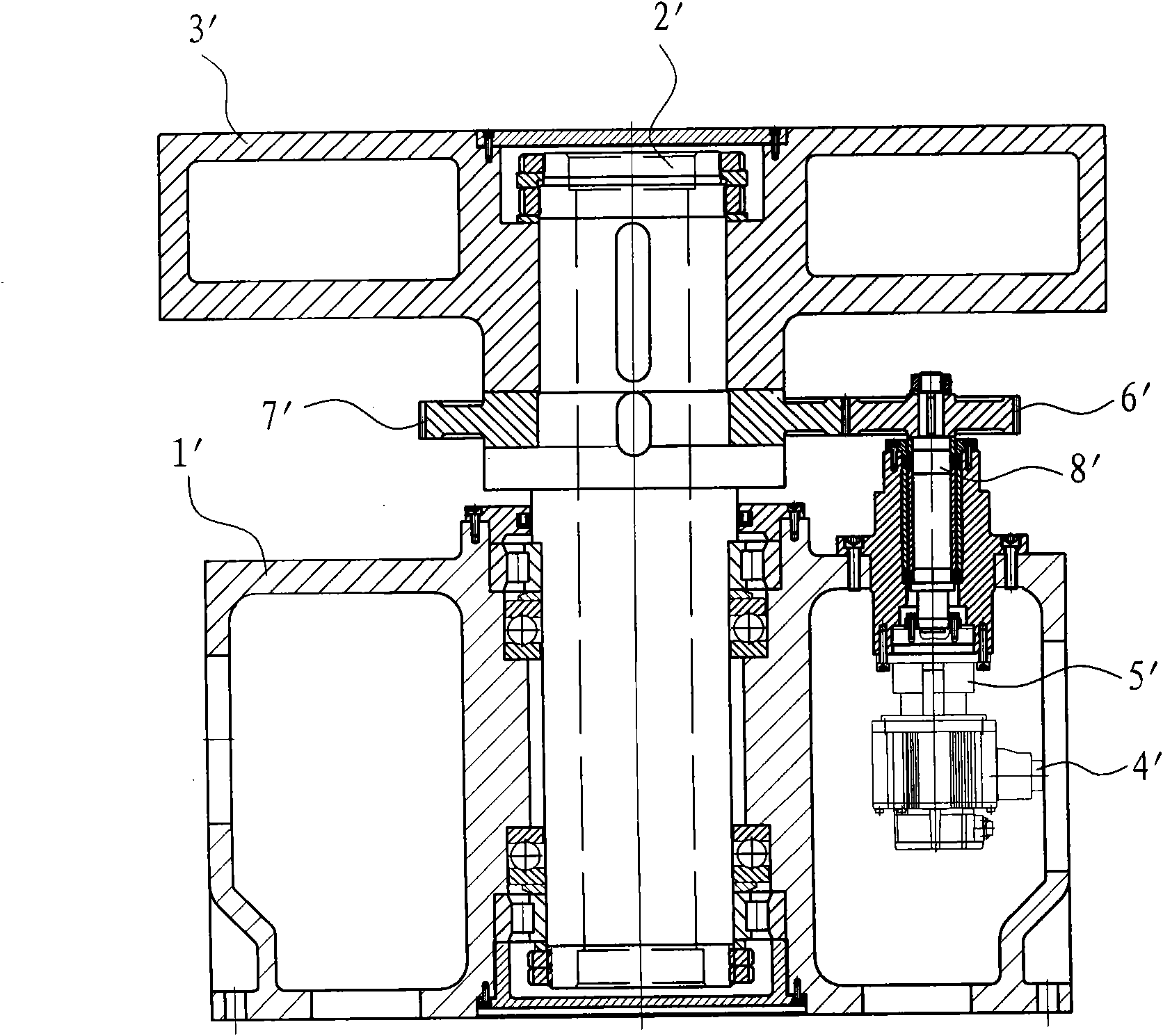

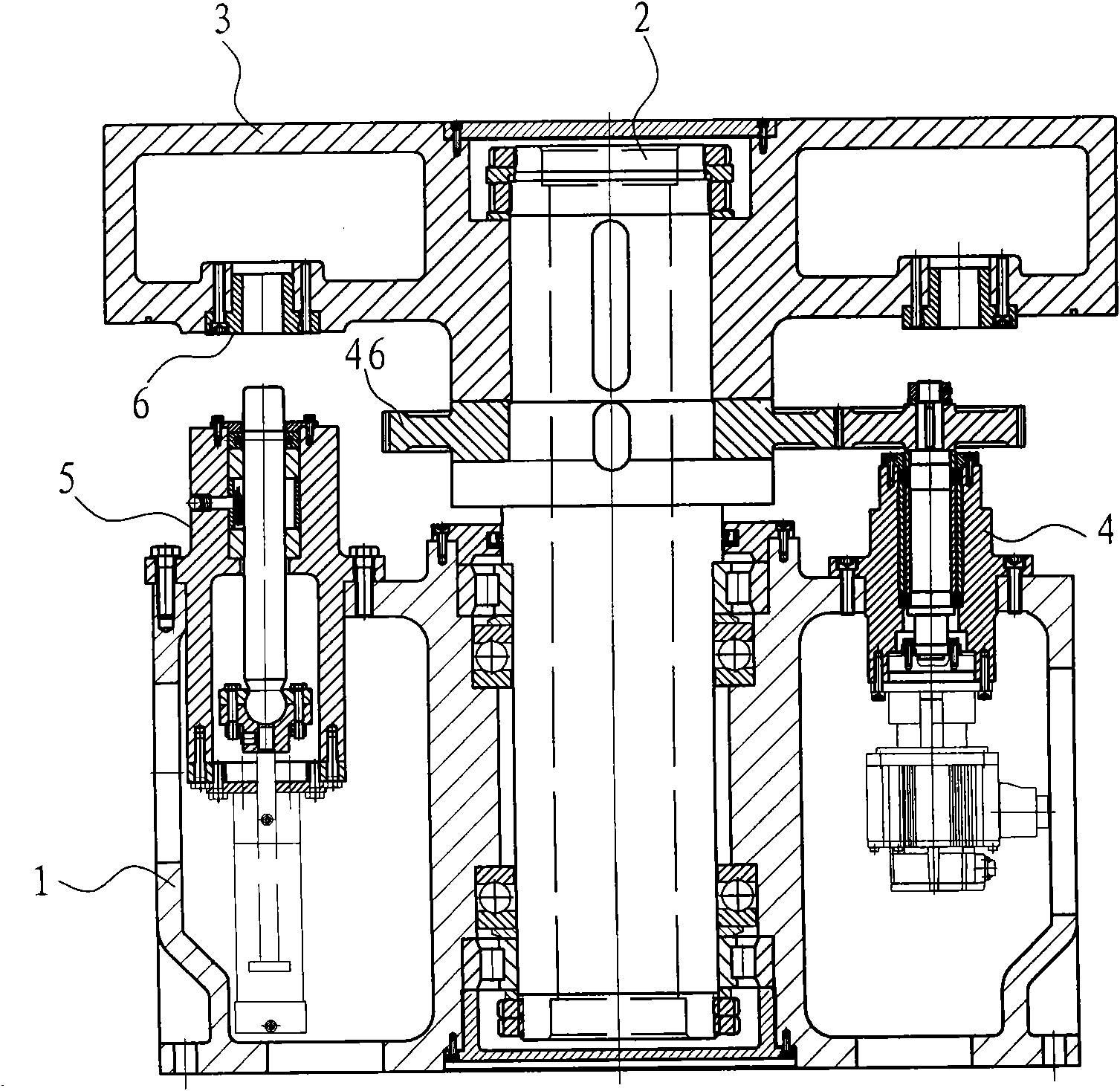

[0014] refer to Figure 2 to Figure 4 , the embodiment discloses a vertical rotary table for a CNC machine tool, which includes a base 1, a rotating shaft 2, a workbench 3, a rotary drive device 4, two indexing positioning devices 5 and four taper pin sleeves 6, wherein:

[0015] The base 1 is used to fix and support other components, the rotating shaft 2 is rotatably arranged vertically on the base 1 through two ball bearings and two roller bearings, and the workbench 3 is fixed on the top of the rotating shaft 2 , Four taper pin sleeves 6 are uniformly arranged on the lower surface of the workbench 3 along the circumferential direction.

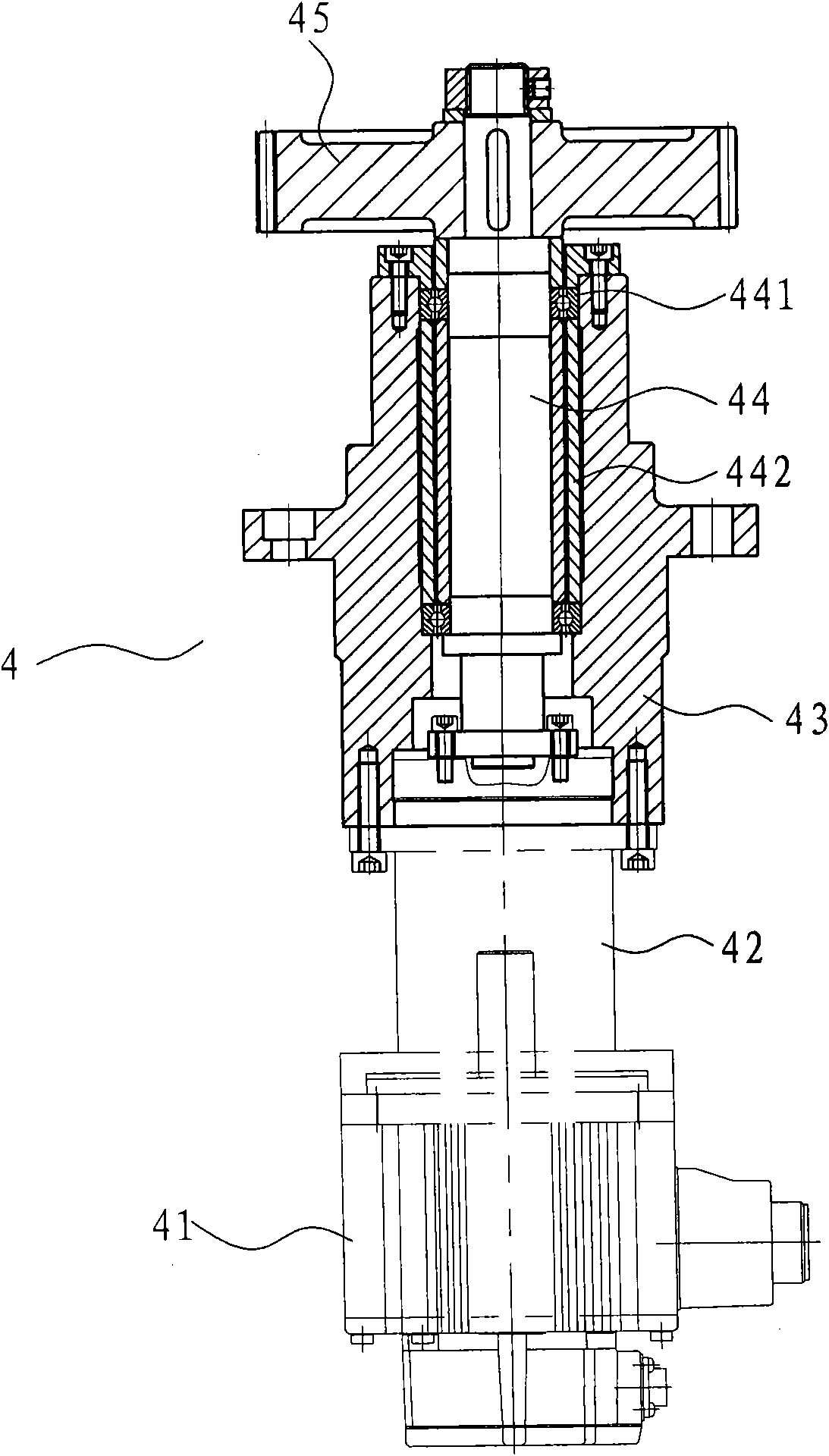

[0016] The rotary driving device 4 is arranged between the base 1 and the rotating shaft 2 to drive the workbench 3 to rotate. The rotary driving device 4 includes a servo motor 41, a reducer 42, a drive shaft fixing seat 43, a drive shaft 44, and a drive shaft. Wheel 45 and driven wheel 46, described driving shaft fixing seat 43 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com