Damping follow rest for turning slender axle

A slender shaft and tool holder technology, applied in turning equipment, tool holder accessories, large fixed members, etc., can solve the problems of tool chipping, affecting production efficiency and efficiency, tool wear, etc., to ensure the processing size and The effect of shape tolerance, improving product qualification rate and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

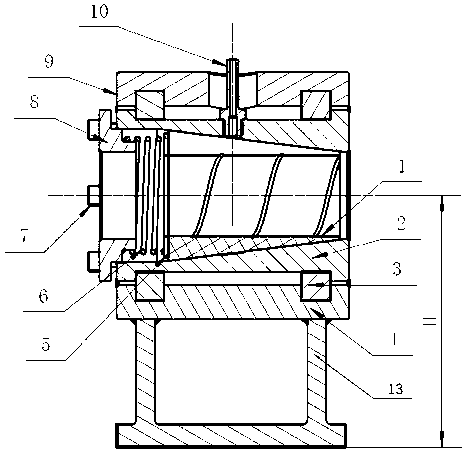

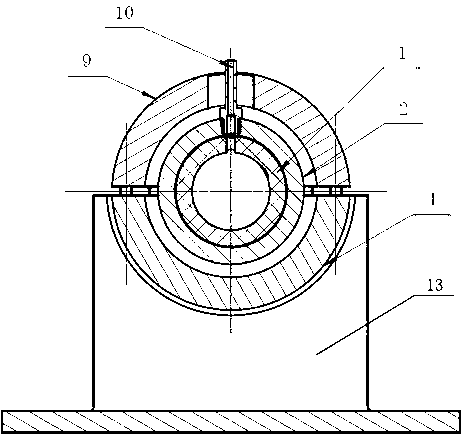

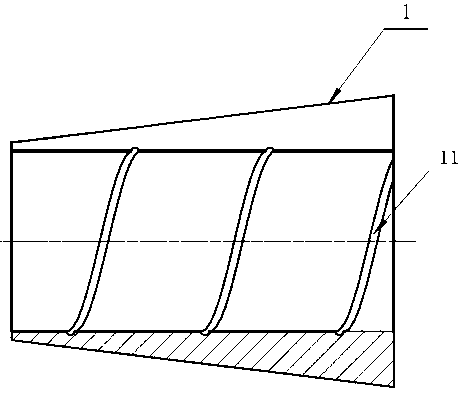

[0030] Such as Figures 1 to 4As shown, the present invention is a kind of vibration-damping tool rest for turning slender shafts. A support 13 is installed on the slide plate of the lathe, and a semi-cylindrical lower support 4 is installed on the support 13. The lower support 4 passes through the Bolts and connection methods are fixedly connected with an upper support 9, and the upper support 9 cooperates with the lower support 4 to form a cylindrical structure. Its interior is hollow, and a The fixed sleeve 2, the overall exterior of the fixed sleeve 2 is cylindrical, and two ring-shaped grooves parallel to each other are arranged on the inner side walls of the upper support 9 and the lower support 4, and an adjusting ring is installed in the groove 3. The adjustment ring 3 is two semi-annular structures, which match the groove and fit on the outer surface of the fixed sleeve 2. After the upper support 9 and the lower support 4 are connected by screws, the adjustment ring 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com