An experimental device for simulating the excavation of tunnels crossing faults

A technology of tunnel excavation and experimental device, applied in the field of tunnel testing, can solve the problems of large deviation of test results, blockage of jack volume, limited number of steel plates, etc., and achieve the effect of avoiding shear damage, improving flexibility and continuous force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

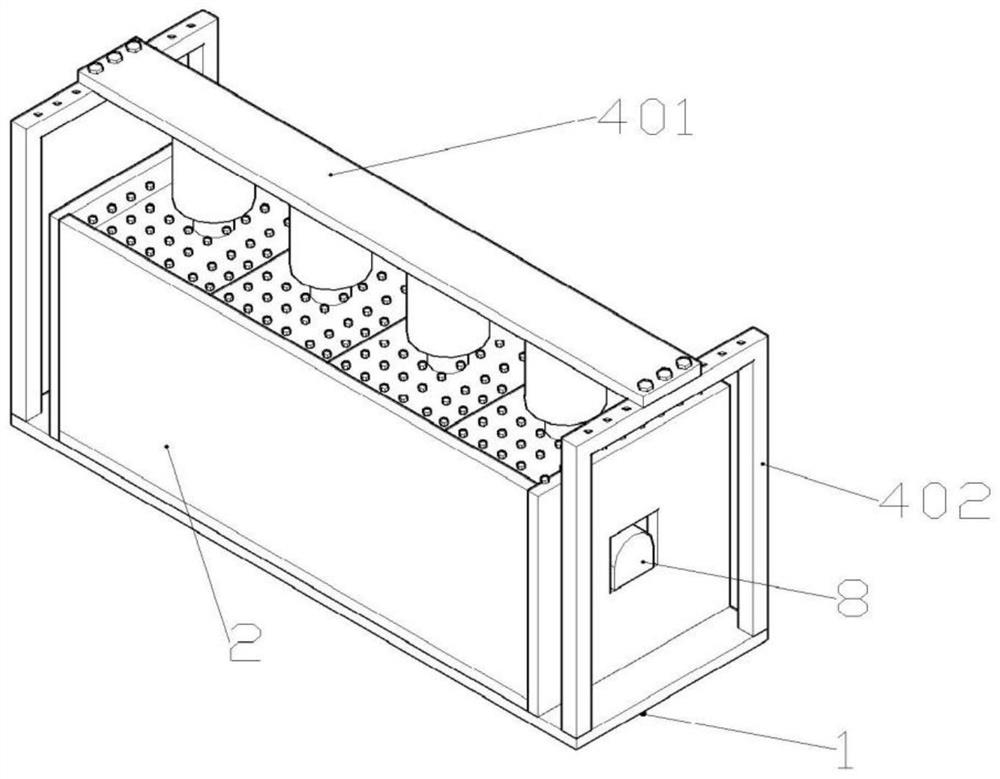

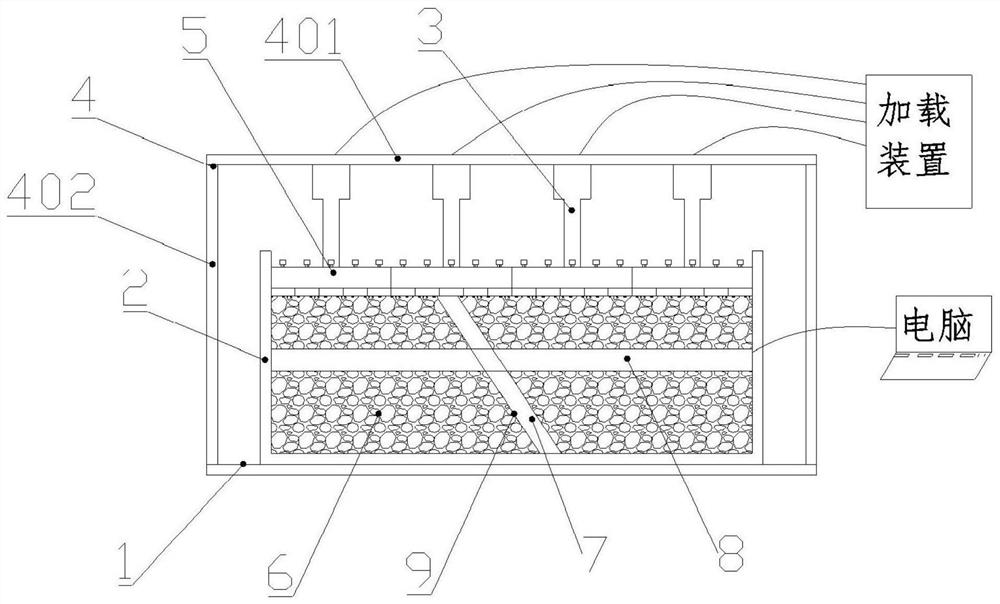

[0035] Such as figure 1 , figure 2 As shown, the present invention is an experimental device for simulating the excavation of tunnels crossing faults, including a substrate 1, a test box 2, a loading structure 3, a support structure 4, a force-transmitting steel plate 5, surrounding rock simulation materials 6, fault simulation materials 7 and Tunnel lining model 8, wherein, the test box 2 and its internal settings belong to the prior art, and will only be briefly described here; the test box 2 is a box-like structure without a cover, and the test box 2 is filled with surrounding rock simulation materials 6 and fault simulation material 7; surrounding rock simulation material 6 and fault simulation material 7 are separated by a gauze 9, that is, the gauze 9 can be used to control the thickness and inclination of the fault; the tunnel lining model 8 passes through the surrounding rock along the length direction of the experimental box 2 The simulation material 6 and the fault...

Embodiment 2

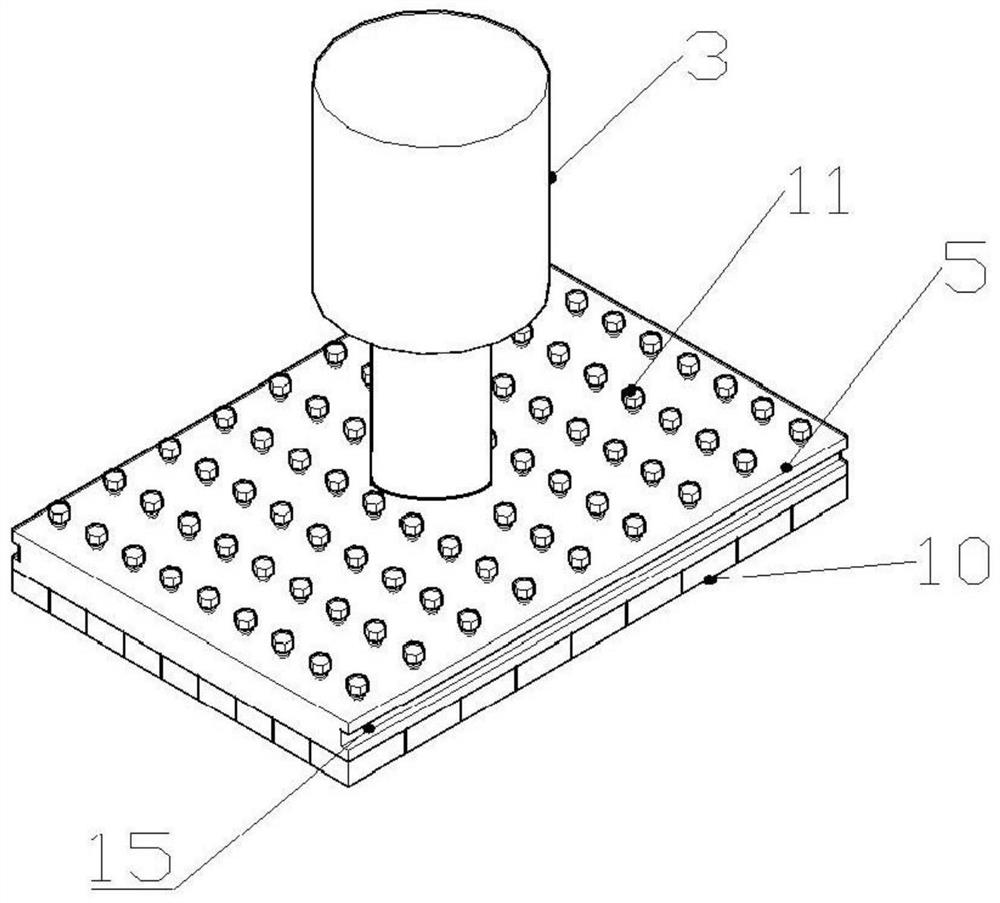

[0038] Such as Figure 3 to Figure 6 As shown, on the basis of Example 1, the force transmission steel plate 5 includes a cover layer 501 and a main body layer 502, the cover layer 501 and the main body layer 502 are connected as one by screws, and the cover layer 501 is A threaded section 503 is provided, and the main body layer 502 is provided with an expanding diameter section 504 and a diameter reducing section 505. The axes of the threaded section 503, the expanding diameter section 504 and the reducing diameter section 505 are all on the same straight line, and the expanding The diameter section 504 is close to the cover plate layer 501, and a connecting rod 12 is arranged in the reducing diameter section 505, and the connecting rod 12 is matched with the inner wall of the reducing diameter section 505, and one end of the connecting rod 12 extends into the expanding diameter section 504, and is connected to The end of the rod 12 located in the enlarged diameter section 5...

Embodiment 3

[0042] On the basis of Embodiment 2, the driving member 11 is a bolt, and the threaded section of the driving member 11 is connected with the threaded section 503 and extends into the enlarged diameter section 504 against the connecting rod 12 for pushing the connecting rod 12 in the axial direction. move.

[0043] The set driver 11 is a bolt, and the bolt includes a head and a screw rod, wherein the screw rod is connected to the threaded section 503 on the cover layer 501 through threads and extends into the enlarged diameter section 504 to contact with the end of the connecting rod 12. The bottom of the screw rod of the part 11 presses against the connecting rod 12 located in the enlarged diameter section 504. When the driving part 11 is rotated, under the cooperation of the screw rod of the driving part 11 and the threaded section 503, the connecting rod 12 can be pushed to drive the force transmission block 10 moves away from the force transmission steel plate 5, which rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com