Cleaver having a crush-forged crank

A technology of protruding parts and machetes, which is applied in the field of machetes to achieve comfortable operation and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

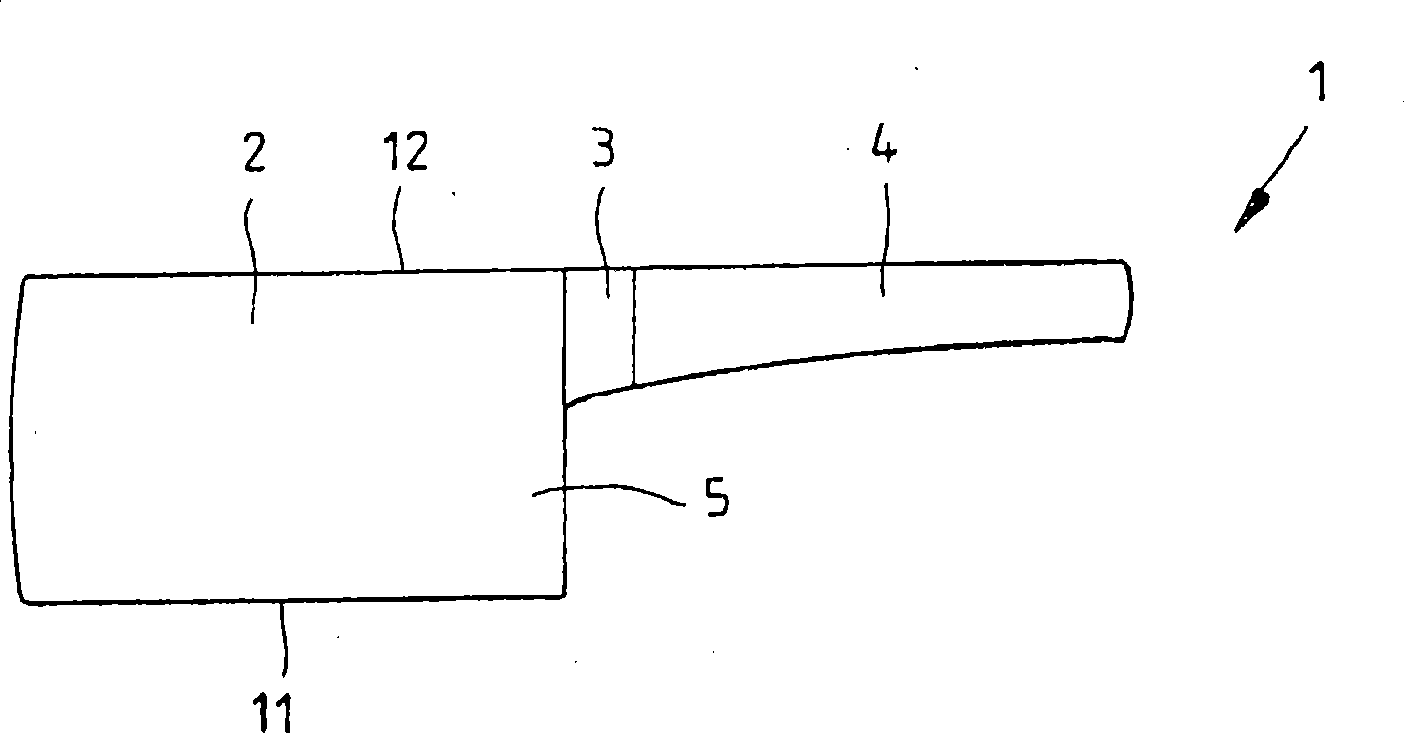

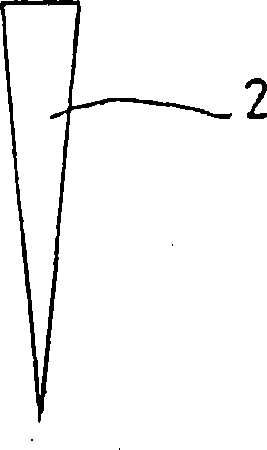

[0026] figure 1 A side view of a conventional machete 1 is shown, which consists of a blade and / or blade 2 , a knob 3 and a handle 4 . Knob 3 is here the connection piece of knife plate and / or blade 2 and handle 4, and has figure 2 The shape shown in the cross-sectional view. When using the machete 1 , it is possible for fingers to come into contact with the blade and / or the shank-side surface 5 of the blade 2 . However, this surface 5 is not adapted to the anatomy of the fingers, so handling the machete 1 is uncomfortable.

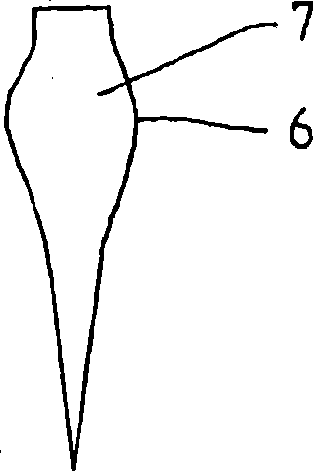

[0027] image 3 A knob 6 according to the invention is shown, which, in contrast to the cross-section of the blade and / or blade 2 , is designed wider than the blade and / or blade 2 at point 7 . This avoids uncomfortable pressure points on the resting finger when using the machete, since the finger rests on the wider point 7 .

[0028] Figure 4 A further advantageous embodiment of a machete 8 according to the invention is shown, which has a knob 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com