L-section steel and concrete combined structural member

A technology of combined structures and structural components, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of large amount of concrete pouring and insufficient mechanical performance, and achieve the effect of improving the level of industrialization, increasing the rate of prefabrication, and ensuring the continuity of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The L-shaped steel-concrete composite structural member of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

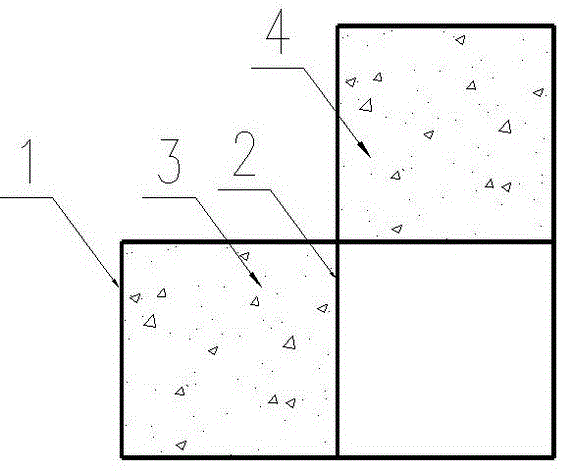

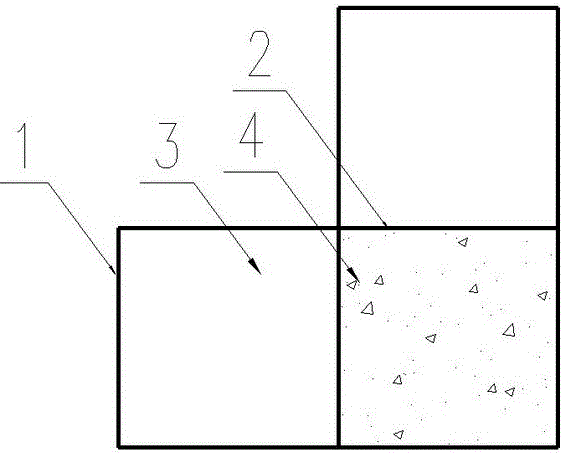

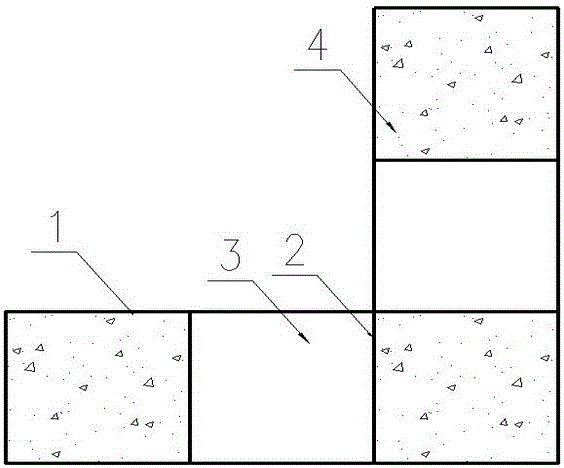

[0035] An embodiment of the L-shaped steel-concrete composite structural member proposed by the present invention, such as figure 1 , the structural member includes an L-shaped steel member 1 with an outer profile formed by connecting steel plates or section steel. There is a partition 2 inside the steel member 1, and the steel member is divided into 3 cavities 3. There is no concrete in the cavity at the corner, and the remaining 2 Each cavity contains concrete 4 (ie precast concrete). In another embodiment, such as figure 2 , The L-shaped steel member 1 is divided into three cavities 3 by the partition plate 2, and there is concrete 4 (that is, precast concrete) in the cavity at the corner, and there is no concrete in the remaining cavities. The number of cavities divided by the partition p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com