Saddle-shaped spatial pre-stressed ring beam

A prestressed, saddle-shaped technology, applied in the direction of joists, girders, trusses, etc., can solve the problems of large tension and bending moment, insufficient stiffness of saddle-shaped space ring beams, etc., to improve stiffness, avoid premature buckling damage, Guarantee the effect of tensioning quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

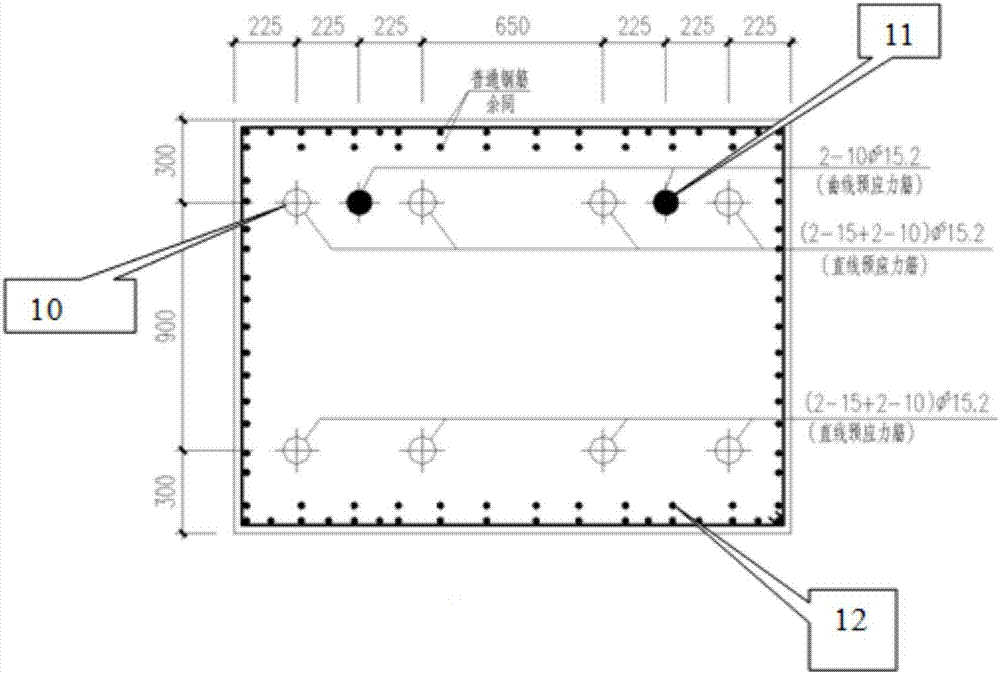

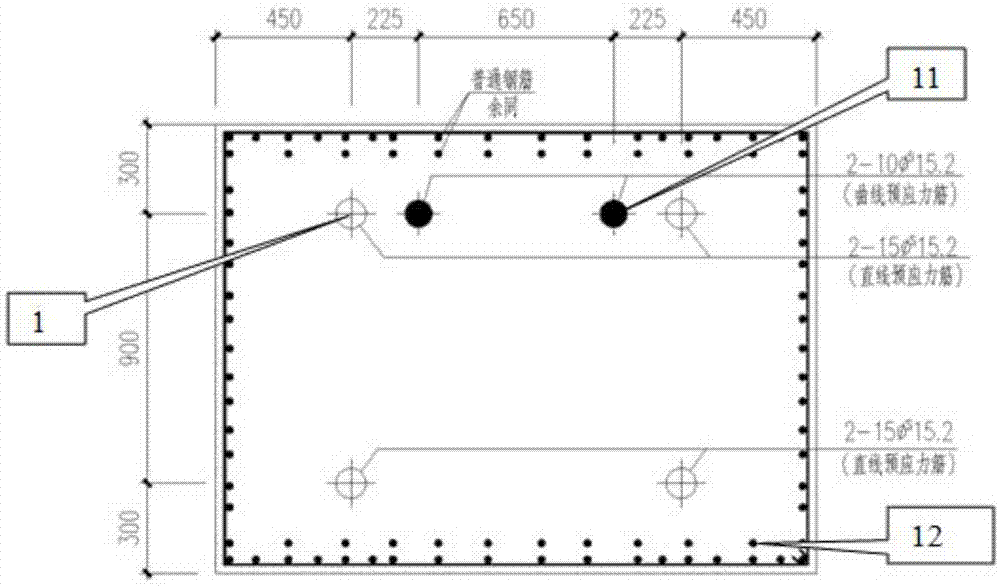

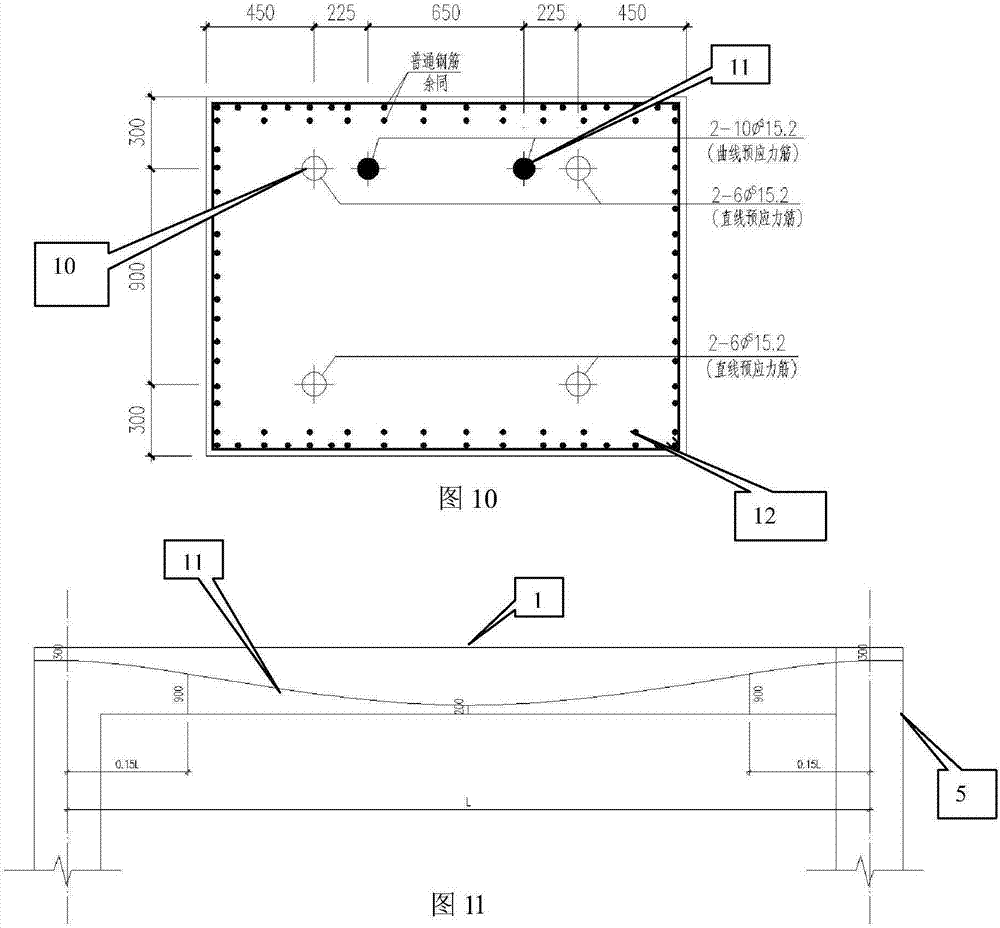

[0029] Take a stadium project as an example to illustrate the saddle-shaped space prestressed ring beam involved in the present invention.

[0030] ①First, arrange a number of inner ring straight columns 5 and outer ring oblique columns 6 equally, high from east to west and low from north to south, such as figure 1 , figure 2 , Image 6 Shown. The maximum height of the inner ring column 5 and the outer ring column 6 is 38.5 meters, the minimum is 22.7 meters, the inner ring column 5 has a maximum height difference of 15.8 meters, and the outer ring column 6 has a maximum height difference of 15.8 meters. The spacing is 20 meters, the spacing of each outer ring diagonal column 6 is 22 meters, the minimum distance between the top of the inner ring straight column 5 and the top of the outer ring diagonal column 6 is 10 meters, the bottom of the inner ring straight column 5 and the outer ring diagonal column The minimum distance of bottom 6 is 16 meters.

[0031] ② Then set the saddl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com