Notch-key type prefabricated member connection node and connection method

A technology of prefabricated components and connecting nodes, applied in the direction of building structure, construction, etc., can solve the problems of easy cracking, affect the performance of use, affect the mechanical performance, etc., and achieve the effect of continuous force, reliable connection and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

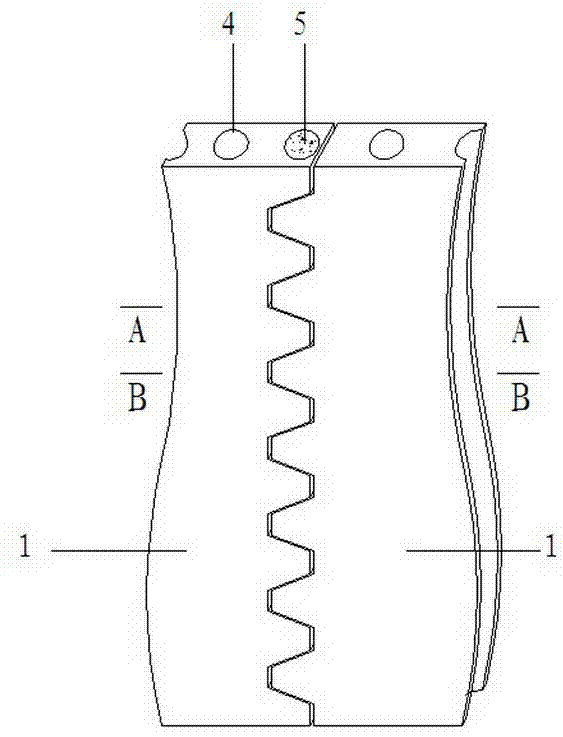

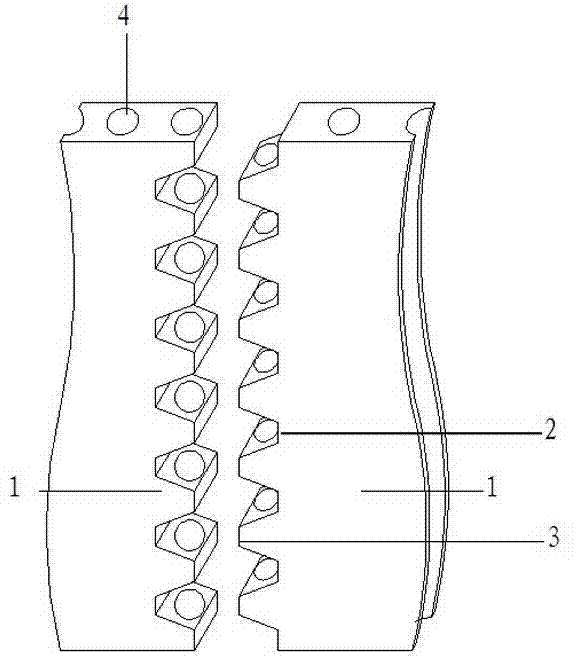

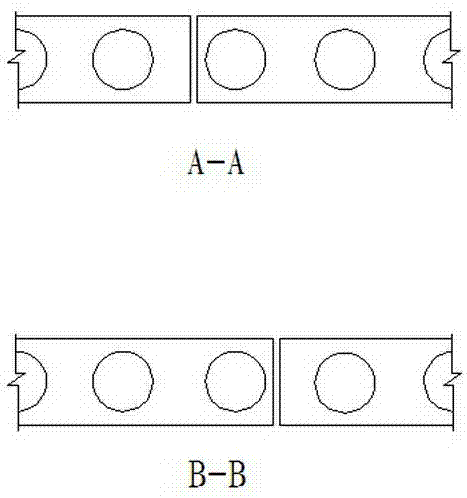

[0031] figure 1 , figure 2 and image 3 It is a schematic diagram of an embodiment of the connection node of the slot-and-key type prefabricated component of the present invention. The longitudinal edge of the prefabricated concrete component 1 is provided with transverse grooves 2, which are arranged alternately with the protrusions 3; The transverse grooves 2 intersect; the protrusions of the prefabricated components on one side of the node extend into the grooves of the prefabricated components on the other side, and there is at least one longitudinal hole at the near edge of the prefabricated components on both sides that is partially or completely overlapped together to form a superimposed longitudinal Concrete is poured in the superimposed longitudinal hole 5 and the node gap to form a slot-and-key node.

[0032] The connection method of the slot-and-key type prefabricated component connection node is characterized in that it includes the following steps: (1) transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com