Ultrasonic liquid knife impacting metal material surface nanocrystallization method and special device thereof

A metal material, liquid knife technology, applied in the field of nanometerization of the surface of metal materials, can solve the problems of high requirements on the outer size of the workpiece, inability to form a sub-micron structure, poor surface finish, etc., achieving low cost, low energy consumption, The effect of easy temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

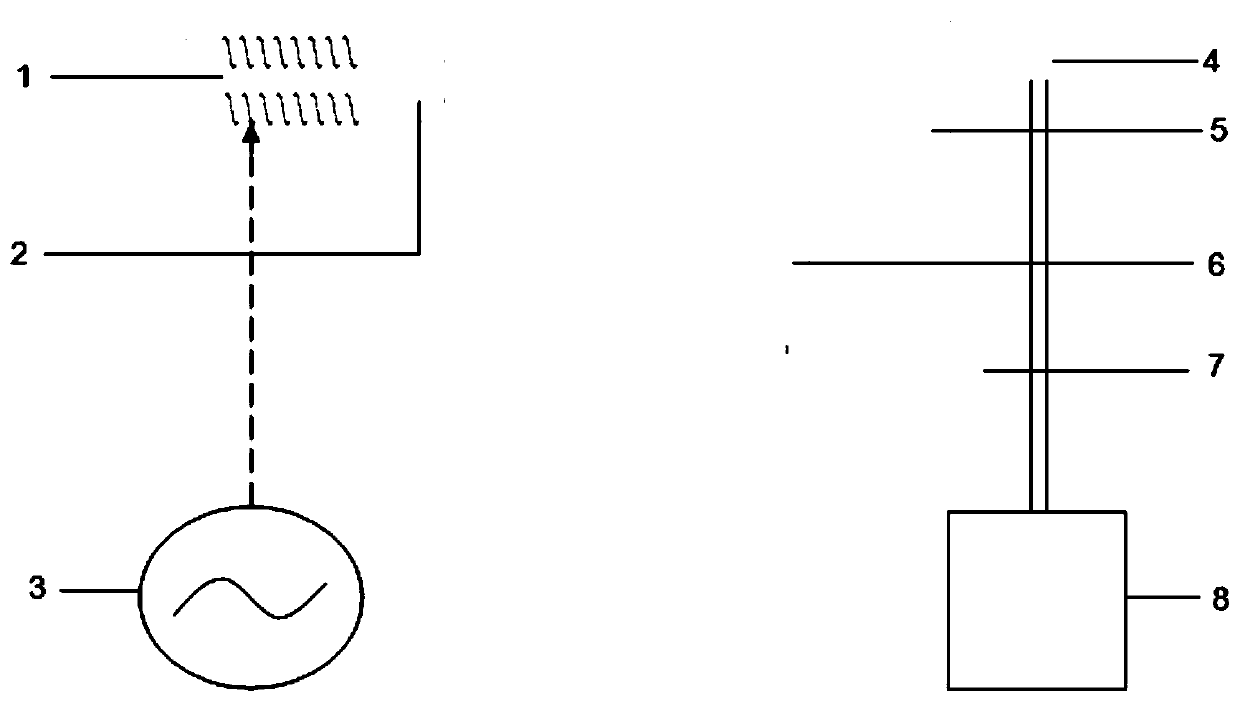

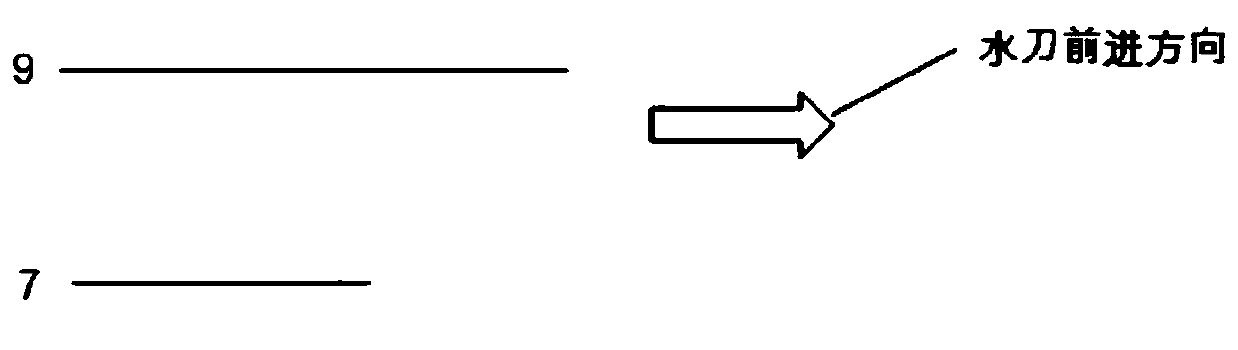

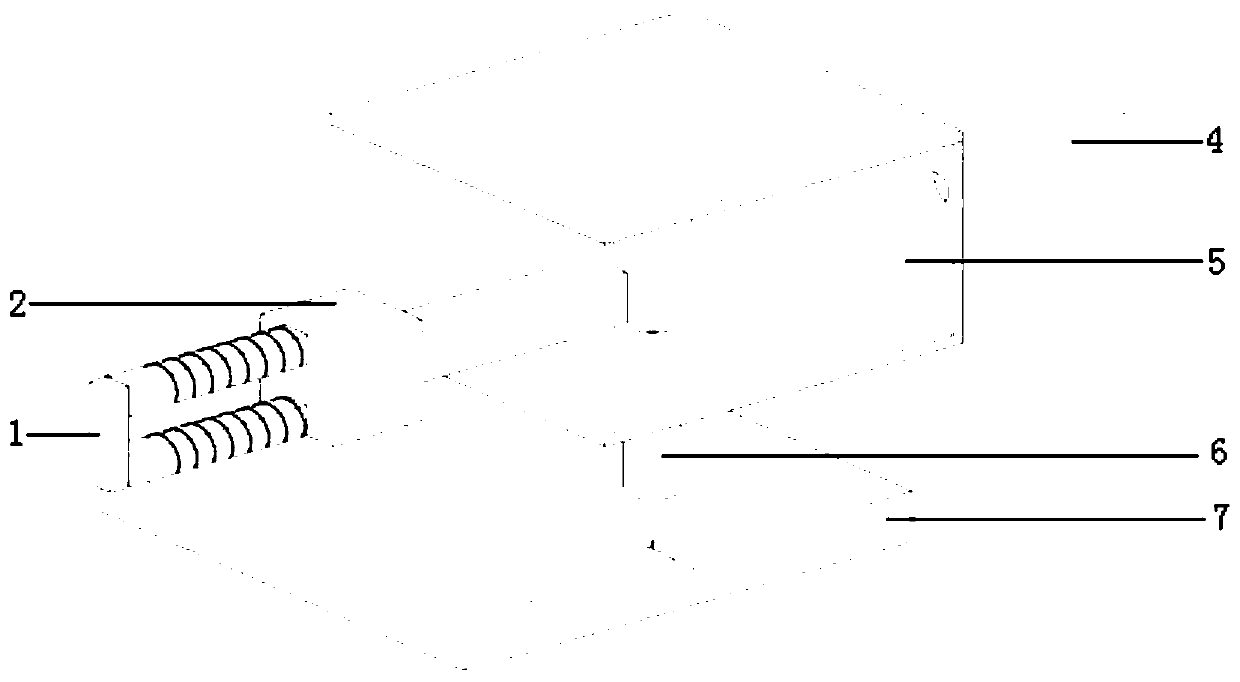

[0042] Below, the structure of the present invention will be described in detail with reference to the drawings and embodiments.

[0043] Such as Figure 1-Figure 3 As shown, the special device for ultrasonic liquid knife impacting metal material surface nanometerization of the present invention includes a liquid knife device and an ultrasonic generating device, and is mainly provided with an ultrasonic transducer 1, an ultrasonic horn 2, an ultrasonic generator 3, A liquid knife inlet pipe 4, an impact liquid tank 5, a liquid knife nozzle 6, a liquid knife booster box 8, the specific structure is as follows:

[0044] The ultrasonic generating device includes an ultrasonic generator 3, an ultrasonic horn 2, and an ultrasonic transducer 1. The liquid knife device includes a liquid knife inlet pipe 4, an impact liquid tank 5, a liquid knife nozzle 6, a liquid knife booster box 8, and an ultrasonic The input end of the transducer 1 is connected to the ultrasonic generator 3, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com