Vegetable planting machine

A technology for planters and vegetables, applied in planting methods, planter parts, agricultural machinery and implements, etc., can solve the problems of infrequent maintenance of knives, high cost, easy damage, etc., to achieve less labor intensity, safe use, structure Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

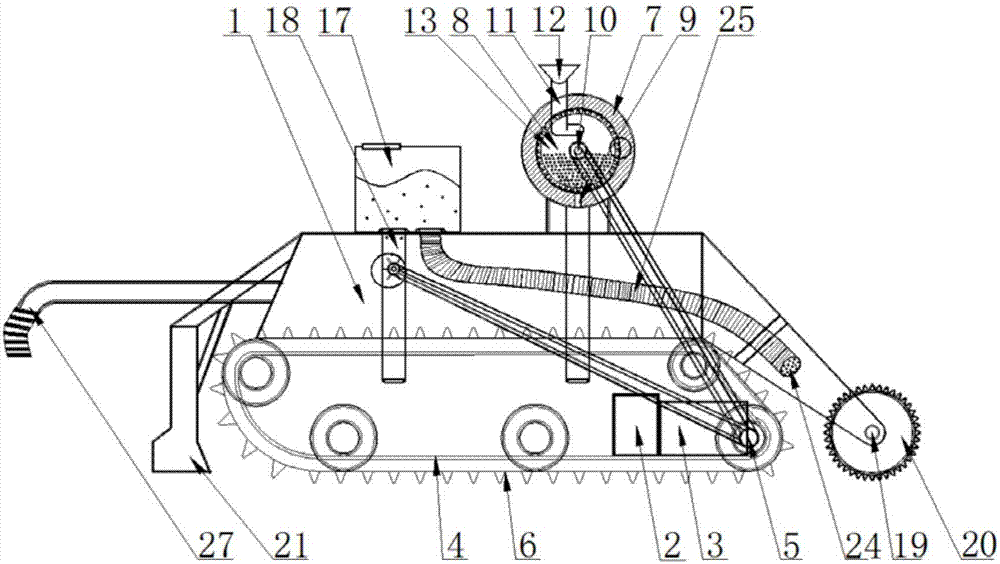

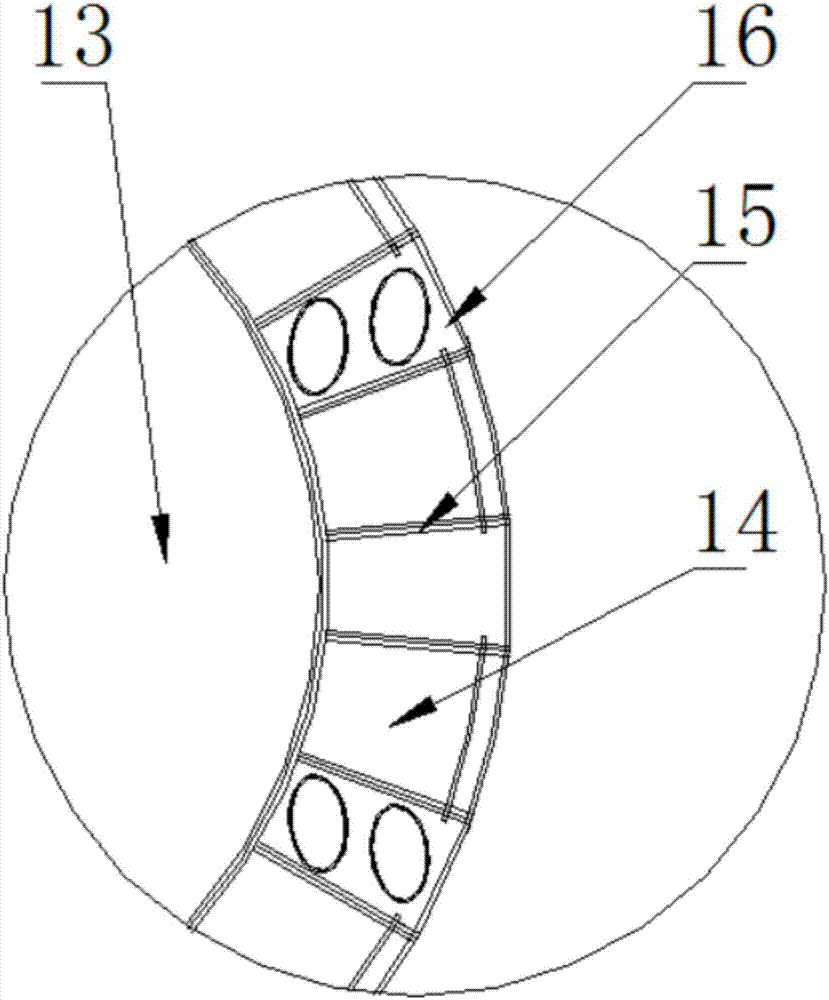

[0019] Example 1, refer to Figure 1-4 , a vegetable planting machine, including a frame 1, the frame is provided with a power mechanism, a walking mechanism, a seed release mechanism, a water supply mechanism and a ditching mechanism, the power mechanism includes a motor 2 and a gearbox 3, the rack The lower part is provided with a traveling mechanism, the traveling mechanism includes a crawler chassis 4, the crawler chassis 4 includes a drive shaft 5 and a crawler 6, the front part of the frame is a gearbox 3 for driving the crawler 6 to travel, and the crawler chassis 4 4. The upper part is provided with a seed release mechanism, which includes a first hollow cylinder 7 and a second hollow cylinder 8, the first hollow cylinder 7 is fixed on the frame 1, and the bottom of the first hollow cylinder has a square shape. Slot 9, a second hollow cylinder 8 is arranged inside the first hollow cylinder, a first rotating shaft 10 is arranged in the center of the second hollow cylind...

Embodiment 2

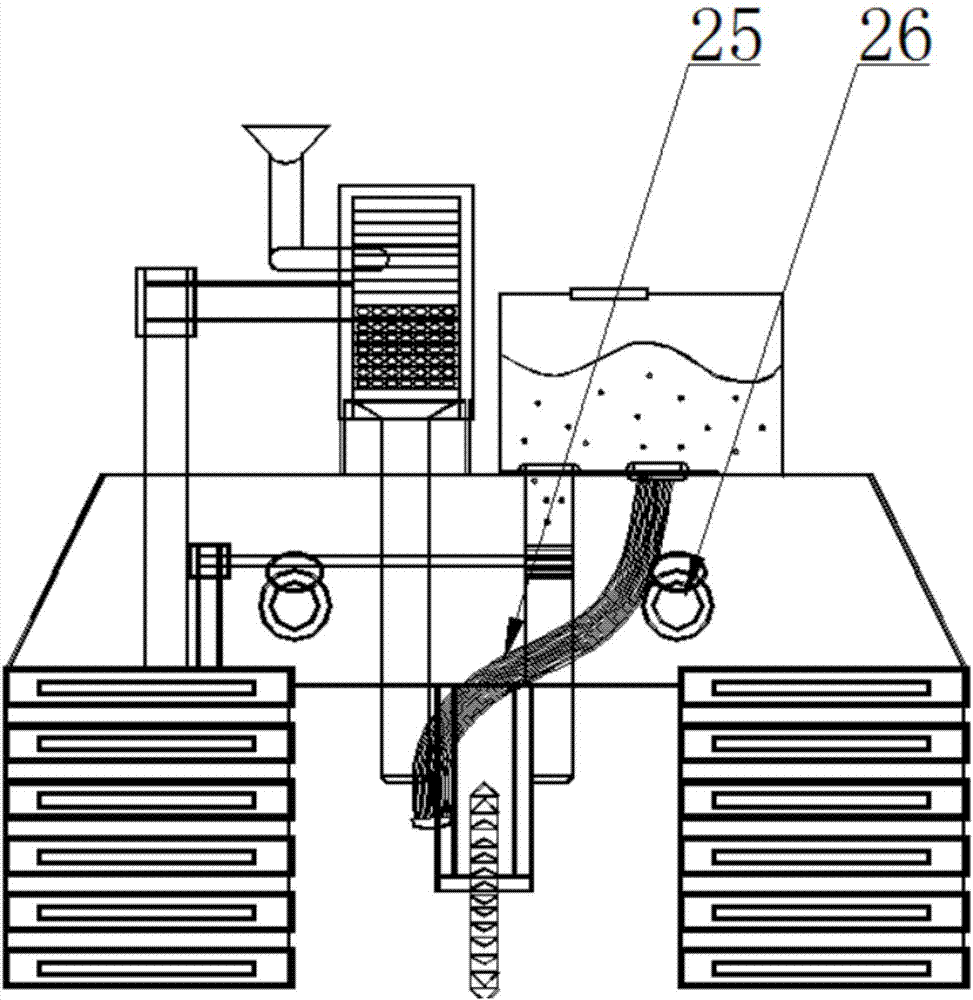

[0020] Embodiment 2, the vegetable planting machine described in Embodiment 1, a water flow restriction mechanism is provided in the middle of the water pipe, and the water flow restriction mechanism includes a second rotating shaft 22, and one end of the second rotating shaft is axially arranged. Separators 23 are evenly arranged, and the transmission mode between the other end of the second rotating shaft and the drive shaft 5 is belt transmission. By restricting the water flow mechanism, the water can be put into the pre-ditched ditch every time, saving a lot of water.

Embodiment 3

[0021] Embodiment 3, the vegetable planting machine described in Embodiment 1, the transmission mode of the first rotating shaft 10 and the driving shaft 5 is a belt drive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com