Molding wheel for drip irrigation belt

A technology of drip irrigation belt and forming wheel, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of incompatibility of forming discs, complicated processing procedures, and high cost, and achieves reduction of processing costs, reduction of processing volume, and improvement of The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

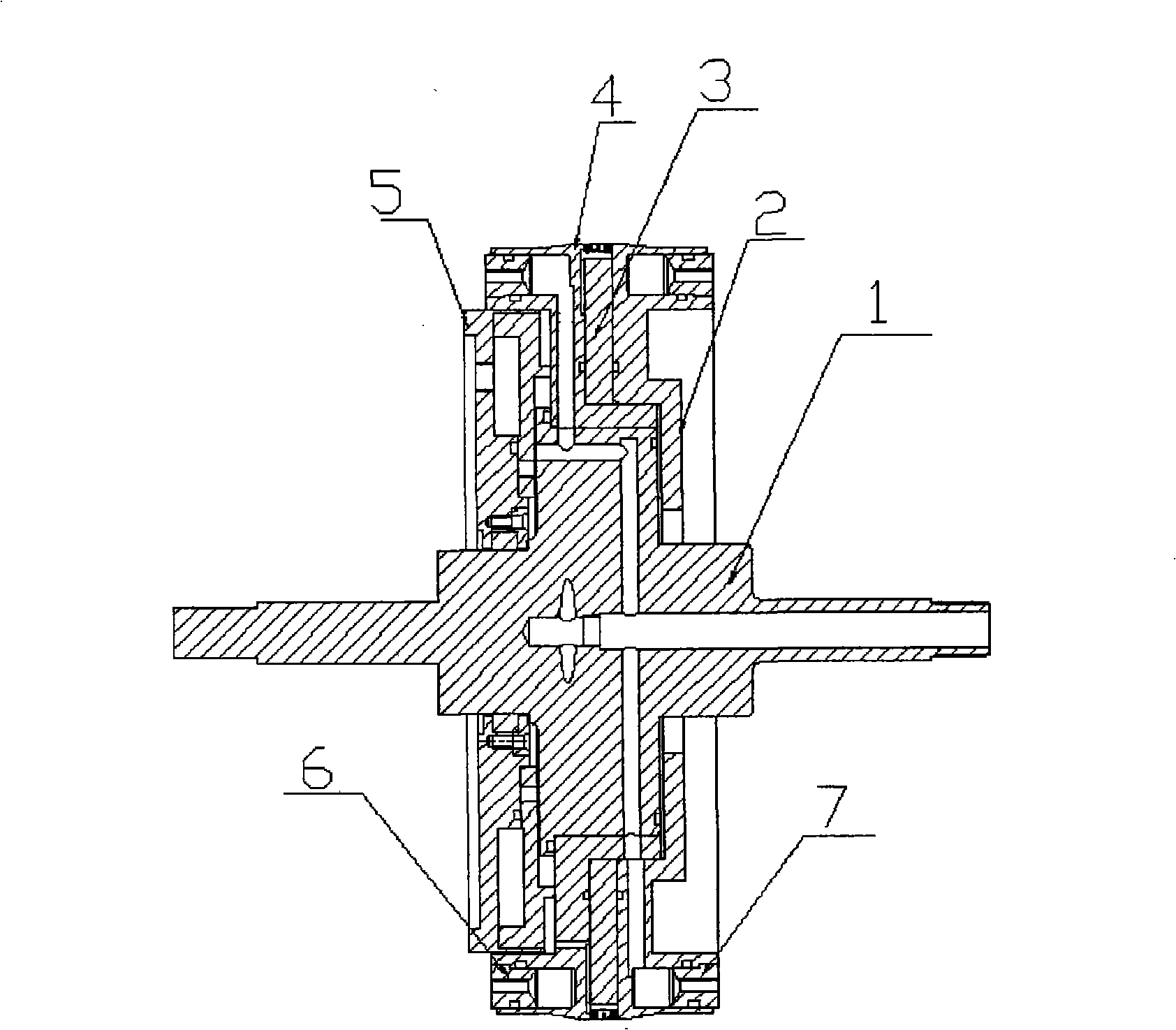

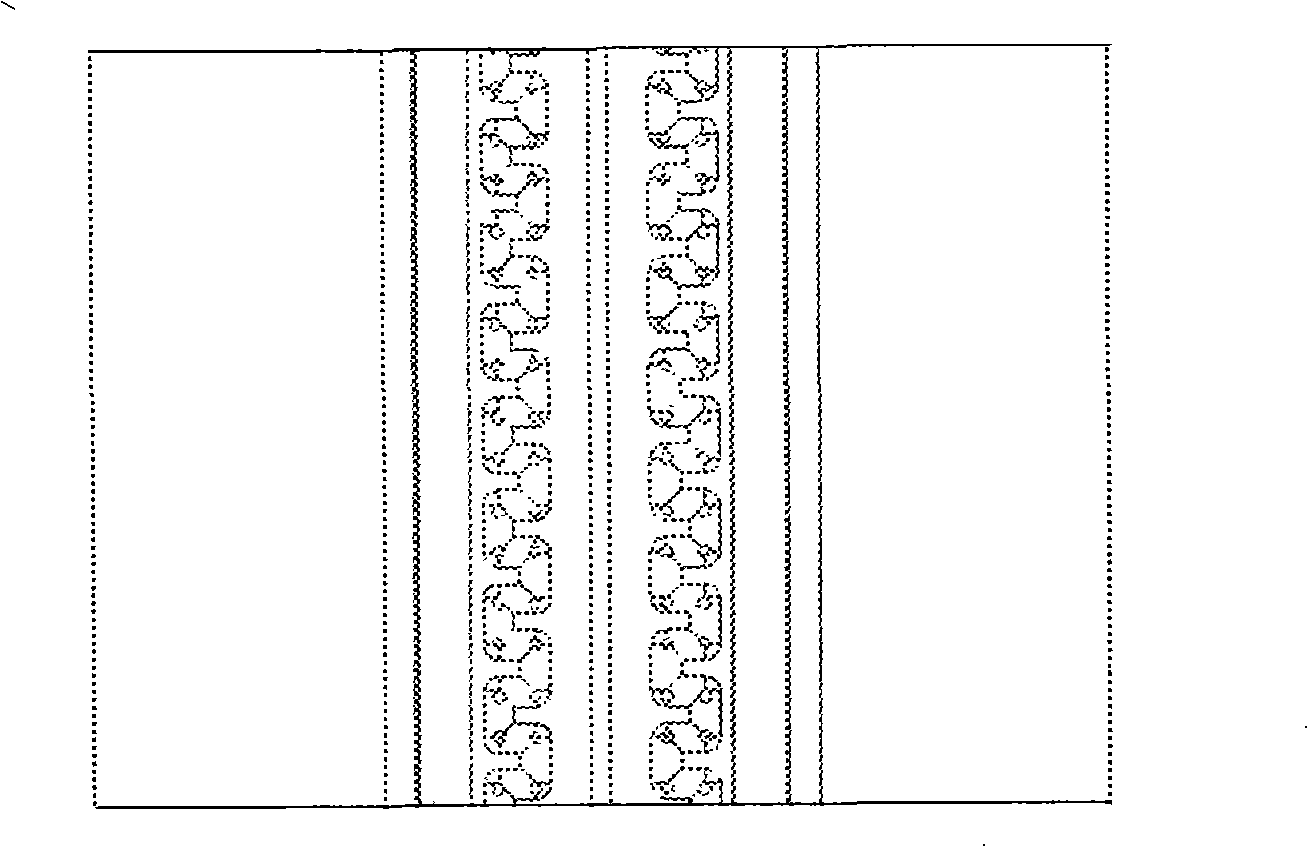

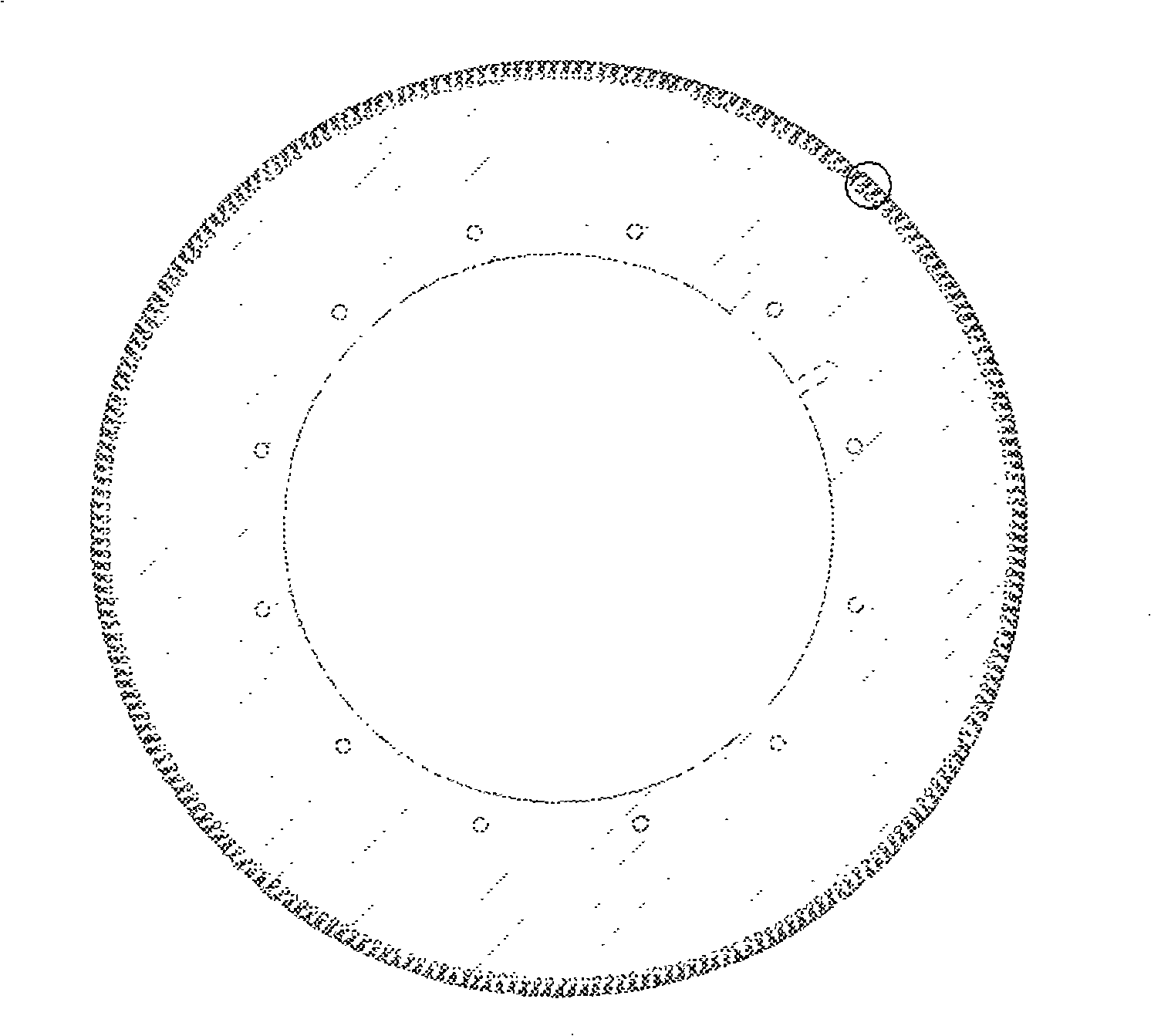

[0012] refer to Figures 1 to 4 , The forming wheel described in this embodiment is mainly composed of shaft 1, right cooling plate 2, forming plate 3, left cooling plate 4, vacuum cover 5, sealing water ring (left) 6, and sealing water ring (right) 7. Install the forming plate 3 on the left cooling plate 4 first, and then assemble it with the right cooling plate 2. The forming plate 3 is located in the middle of the left cooling plate 4 and the right cooling plate 2, at the position corresponding to the water channels of the left cooling plate 4 and the right cooling plate 2 Assemble the sealing water ring (left) 6 and the sealing water ring (right) 7. Then the shaft 1 is installed in the center of the left and right cooling discs, and the vacuum cover 5 is installed on the left end of the shaft. The end surface of the forming plate 3 is evenly distributed with small holes directly connected with the air groove of the left cooling plate 4, and a ring groove is arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com