Combustion control method for four-corner tangential circle boiler

A technology of boiler combustion and control method, applied in the control of superheat temperature, steam superheat, steam generation, etc., can solve problems such as affecting unit efficiency, metal fatigue, strength and life reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation of the combustion control method for a four-corner tangential circle boiler according to the present invention will be described in detail below in conjunction with the accompanying drawings.

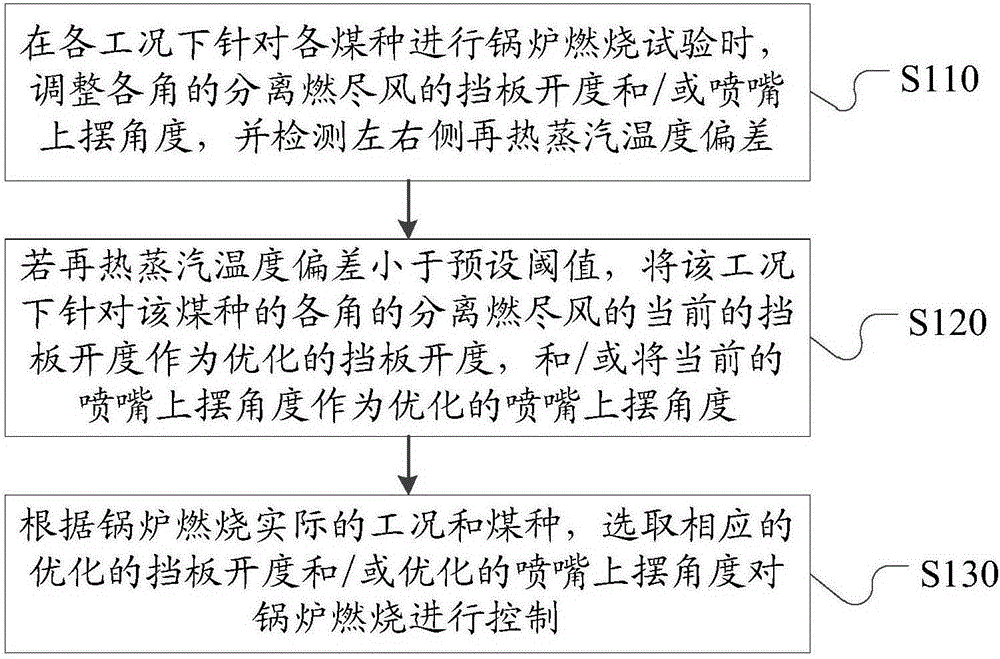

[0015] Such as figure 1 As shown, a combustion control method for a four-corner tangential circle boiler includes steps:

[0016] S110. When conducting boiler combustion tests for various types of coal under various working conditions, adjust the baffle openings and / or nozzle upward swing angles for separating the overburned air at each corner, and detect the temperature deviation of the reheated steam on the left and right sides. At least two of the baffle openings of the separated overburning air are different, and / or at least two of the nozzle upswing angles are different;

[0017] The working condition is the working state of the equipment under the conditions directly related to its action, or the process conditions, etc. Here, each working condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com