Large diameter steel-plastic pipe

A steel-plastic pipe, large-diameter technology, applied in the field of pipelines, can solve the problems of shortened service life, heavy weight, difficult transportation, handling and installation, increased pipeline operation costs and maintenance costs, etc., to improve corrosion resistance, manufacturing costs and The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

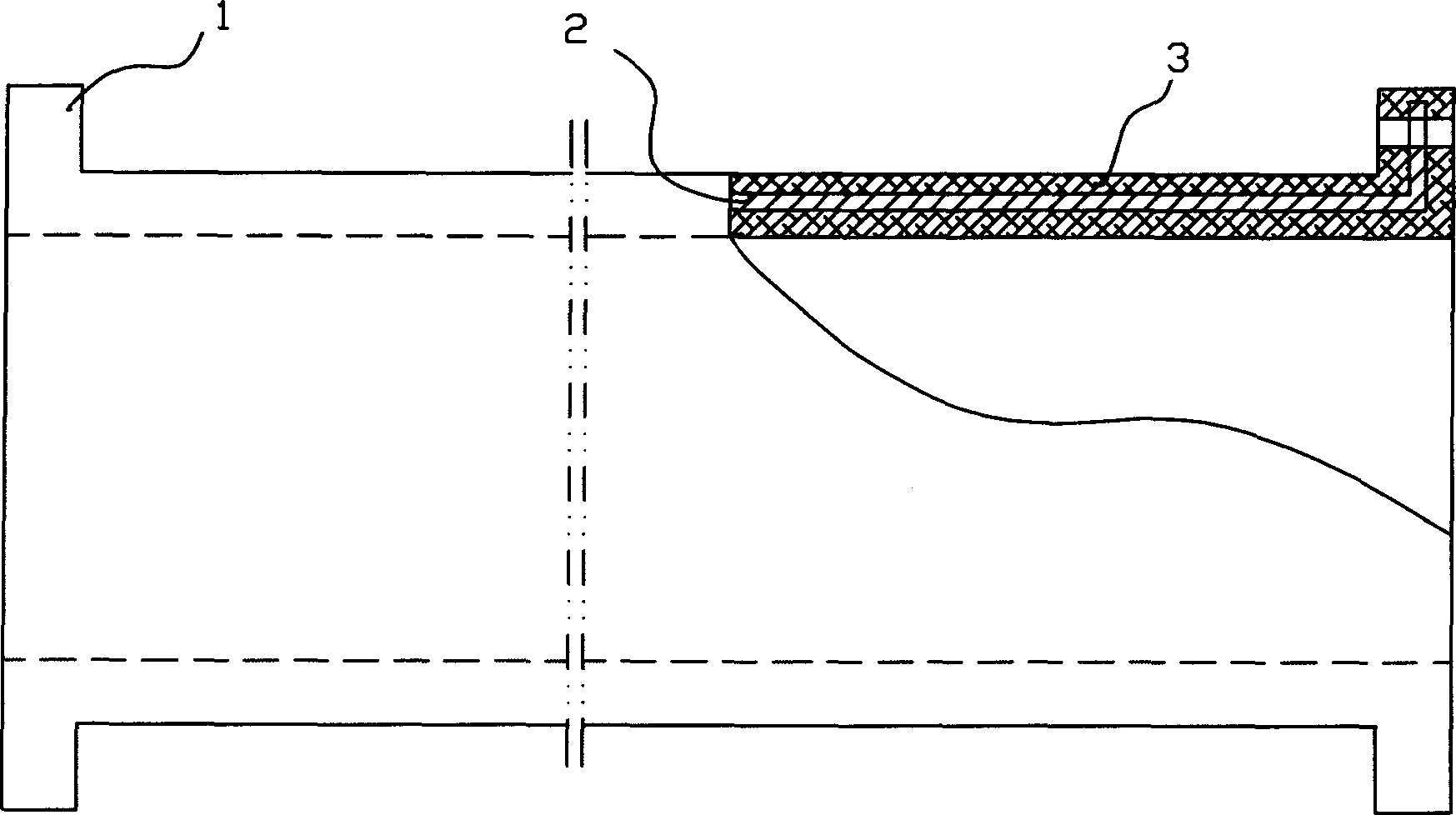

[0019] As shown in the figure, the large-diameter steel-plastic pipe of the present invention includes a pipe body, flanges 1 arranged at the two ports of the pipe body, and the pipe body is made of a steel pipe 2 and coated on the steel pipe 2 The plastic layer 3 on the inner and outer peripheral surfaces is formed; the material of the plastic layer 3 is made by mixing high-density polyethylene, glass fiber, butyl or propyl cellulose acetate according to the following proportions (parts by weight):

[0020] High-density polyethylene: 25 parts; glass fiber: 10 parts; butyl cellulose acetate: 0.5 parts.

[0021] The material ratio of the plastic layer 3 can also be:

[0022] High-density polyethylene: 40 parts; glass fiber: 20 parts; butyl cellulose acetate: 1.5 parts.

[0023] The material ratio of the plastic layer 3 can also be:

[0024] High-density polyethylene: 60 parts; glass fiber: 30 parts; propyl cellulose acetate: 2.5 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com