High-temperature and high-pressure metal sealing ball valve

A metal sealing, high temperature and high pressure technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as jamming, high temperature expansion of ball and valve seat, and floating valve seat loss of floating function. Flexible floating, anti-sedimentation, good running performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

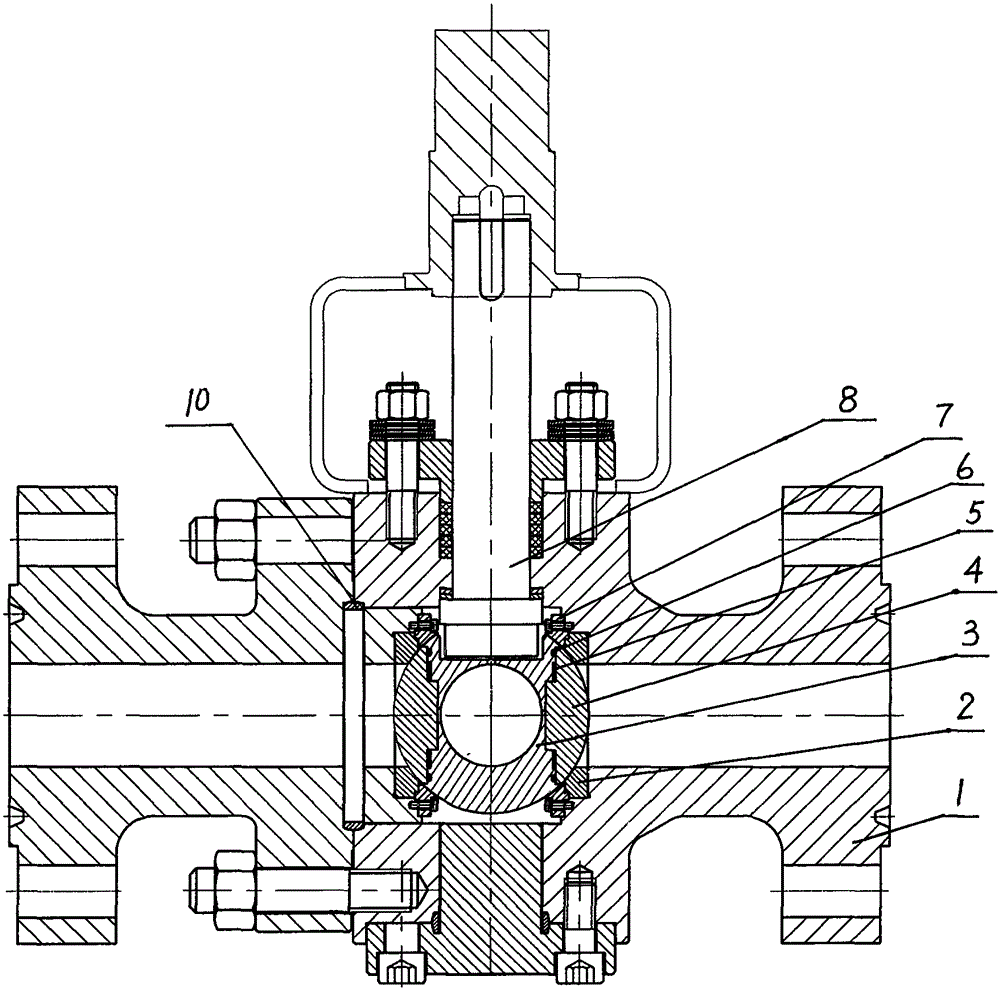

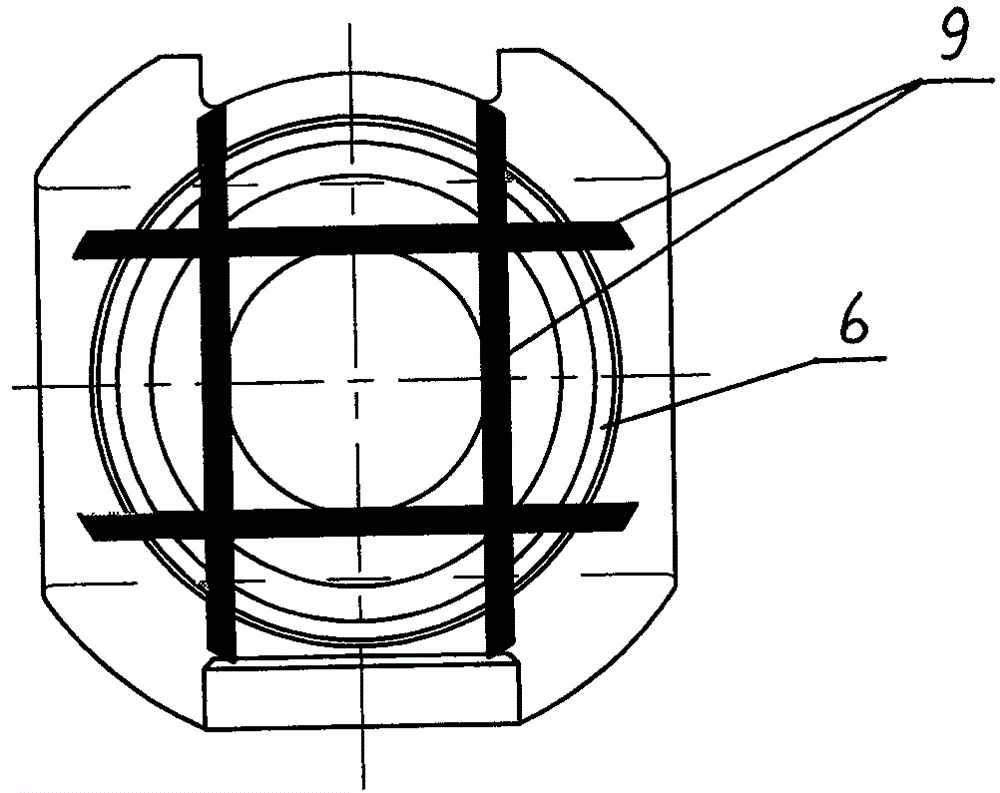

[0010] Such as figure 1 The high-temperature and high-pressure metal-sealed ball valve shown includes a valve body 1, a valve seat 2, a ball 3, and a valve stem 8. The valve seat 2 is respectively provided in the inlet and outlet channels of the valve body 1, and the diameter of the valve body 1 channel is made in the ball 3. Equal through holes, the sealing surface of the valve seat 2 and the surface of the sphere 3 are spray-welded with wear-resistant materials, and the inner surface of the through-hole of the sphere 3 is sprayed with wear-resistant materials; a plane is respectively made on the sphere 3 on both sides of the centerline of the through-hole of the sphere 3. The two planes are symmetrically arranged on the sphere 3 on both sides of the plane where the centerline of the valve stem 8 and the centerline of the through hole of the sphere 3 are located, and the three planes are parallel to each other, that is, the plane passing through the centerline of the valve ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com