Heat-resistant and wear-resistant metal seal ball valve

A wear-resistant metal, sealing ball valve technology, used in valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of high temperature expansion of the ball and valve seat, stuck, floating valve seat loss of floating function, etc. Ensure a flexible floating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

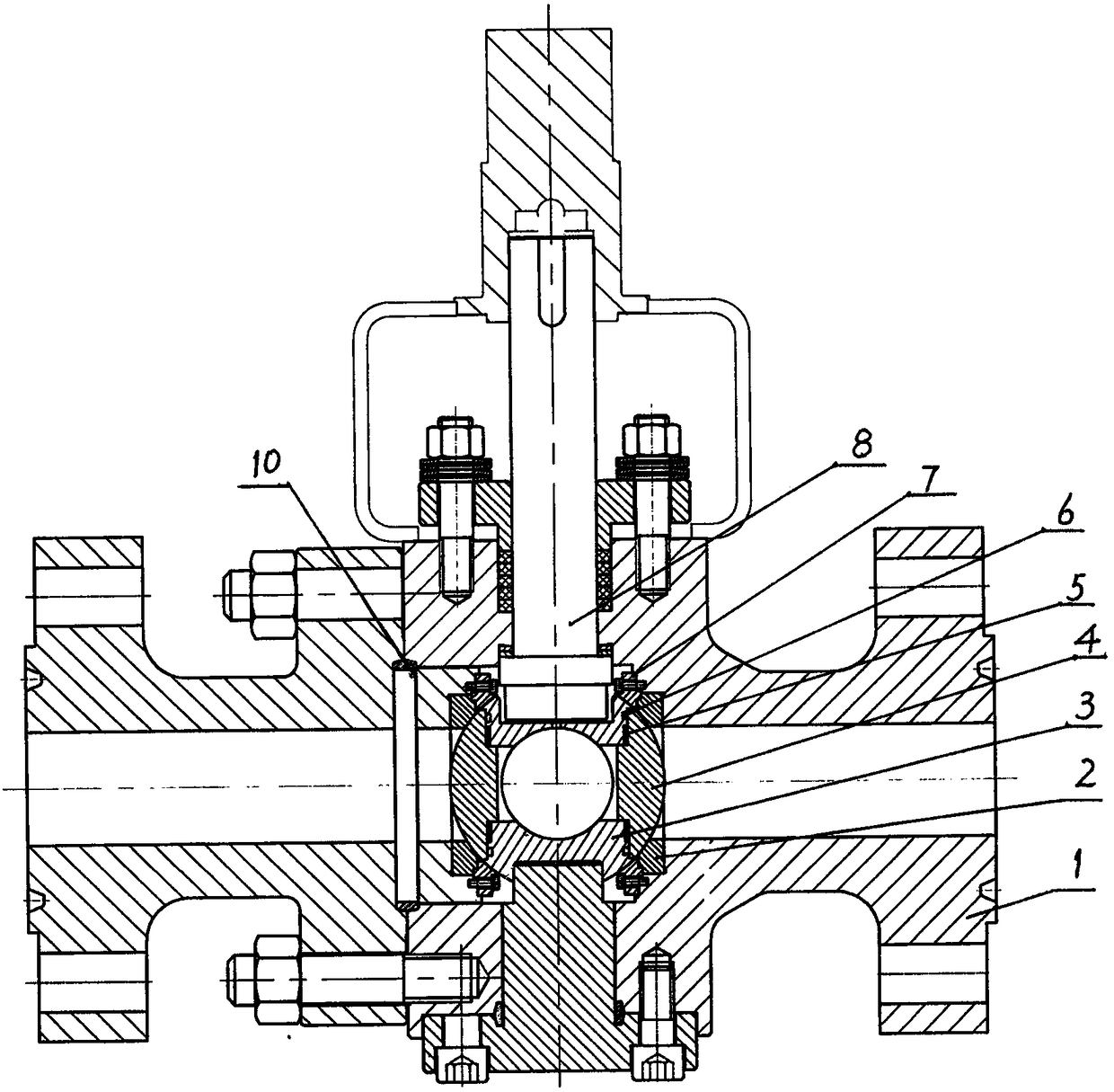

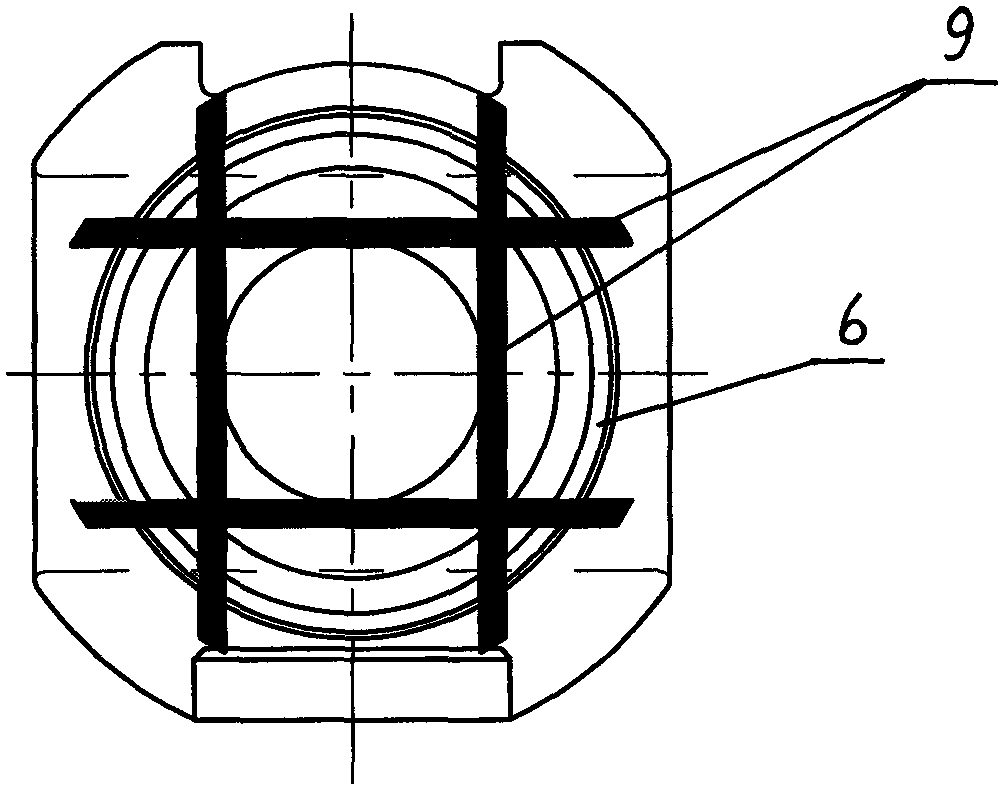

[0010] Such as figure 1 The temperature-resistant and wear-resistant metal-sealed ball valve shown includes a valve body 1, a valve seat 2, a ball 3, and a valve stem 8. The valve body 1 is provided with a valve seat 2 in the inlet and outlet passages, and the ball 3 is made with valve body 1. A through hole with the same channel diameter, the sealing surface of the valve seat 2 is spray-welded with wear-resistant materials, the outer surface of the ball 3 and the inner surface of the through hole are sprayed with wear-resistant materials; a plane is respectively made on the ball 3 on both sides of the center line of the through hole of the ball 3, The two planes are symmetrically arranged on the sphere 3 on both sides of the plane where the centerline of the valve stem 8 and the centerline of the through hole of the sphere 3 are located, and the three planes are parallel to each other, that is, through the centerline of the valve stem 8 and the centerline of the through hole o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com