Floating mechanism for main shaft of double countershaft transmission

A technology of double intermediate shafts and floating mechanism, which is used in mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problems of difficult assembly, easy jamming of hinged ball joints, scattered structure of floating mechanism, etc. Pre-adjustment, easy assembly, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner.

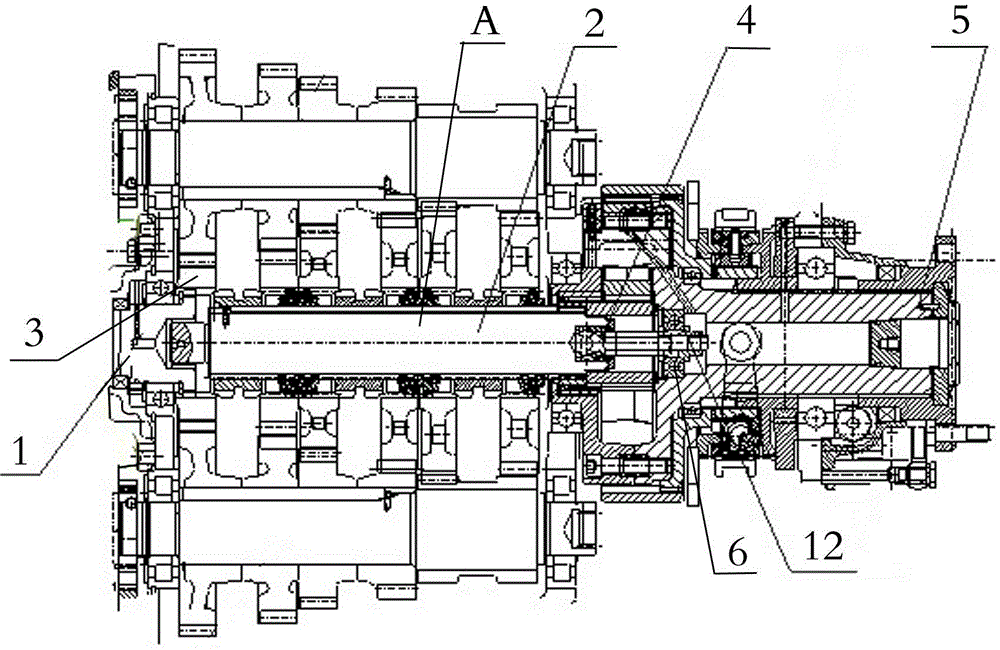

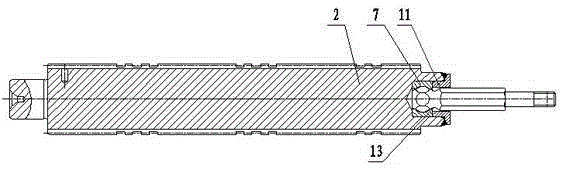

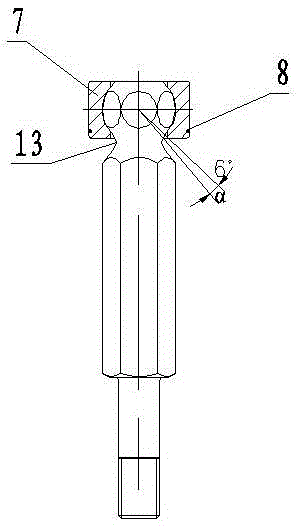

[0018] As shown in the accompanying drawings, a floating mechanism for the main shaft of a double countershaft transmission includes a main shaft 2 connected to the input shaft 1, a floating gap is provided between the front end of the main shaft 2 and the bushing 3 of the input shaft 1, and the main shaft 2 The end is fixedly installed on the bearing 6 on the output shaft 5 through an integral joint bearing unit 4. The integral key bearing unit 4 includes a bearing outer ring 7, a self-locking spring 8, and a ball stud. The bearing outer ring 7 is located at In the inner hole of the main shaft, the bearing outer ring 7 includes two hemispheres split along the axis, and the two hemispheres are fixedly connected as a whole by a self-locking spring 8. The ball cavity of the bearing outer ring 7 is installed with The ball h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com