Apparatus for pressure based blocking process for lens manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

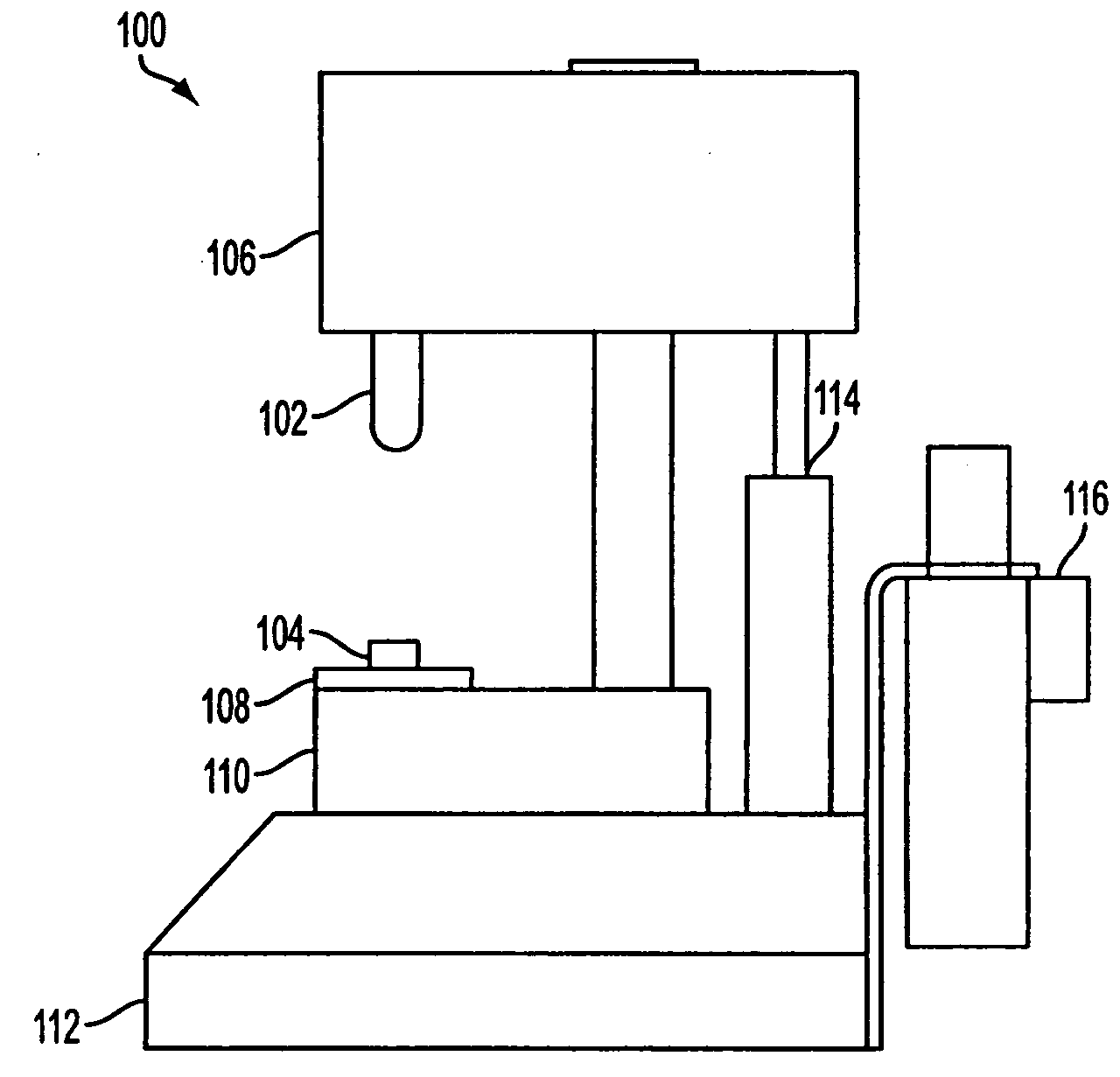

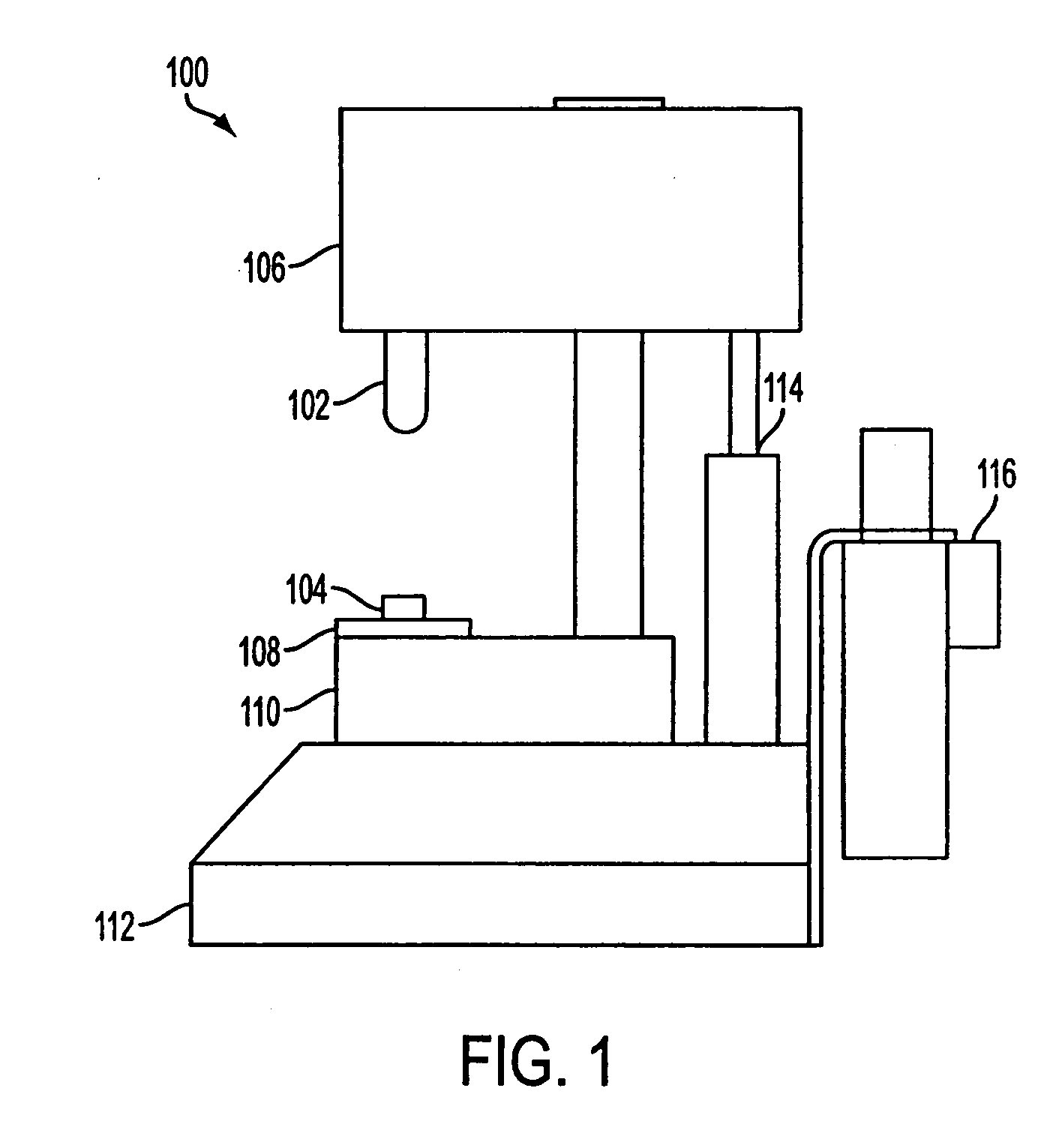

[0039] According to an embodiment of the invention illustrated in FIG. 1, a blocking apparatus 100 of the invention may include, for example, a block 102 (e.g., a fixture, an arbor, etc.), a block head 106, a button 104 (e.g., unprocessed contact lens), a seat 108, a seat stage 110, a base 112, a force control mechanism 114, and a force adjustment mechanism 116. Block 102 may be coupled to block head 106. Block 102 and block head 106 may be movable in an axis vertical to blocking apparatus 100. While block 102 and block head 106 are described herein as operating in a vertical axis, the invention may also be constructed to operate block 102 and block head 106 in a horizontal or any other axis as would be apparent.

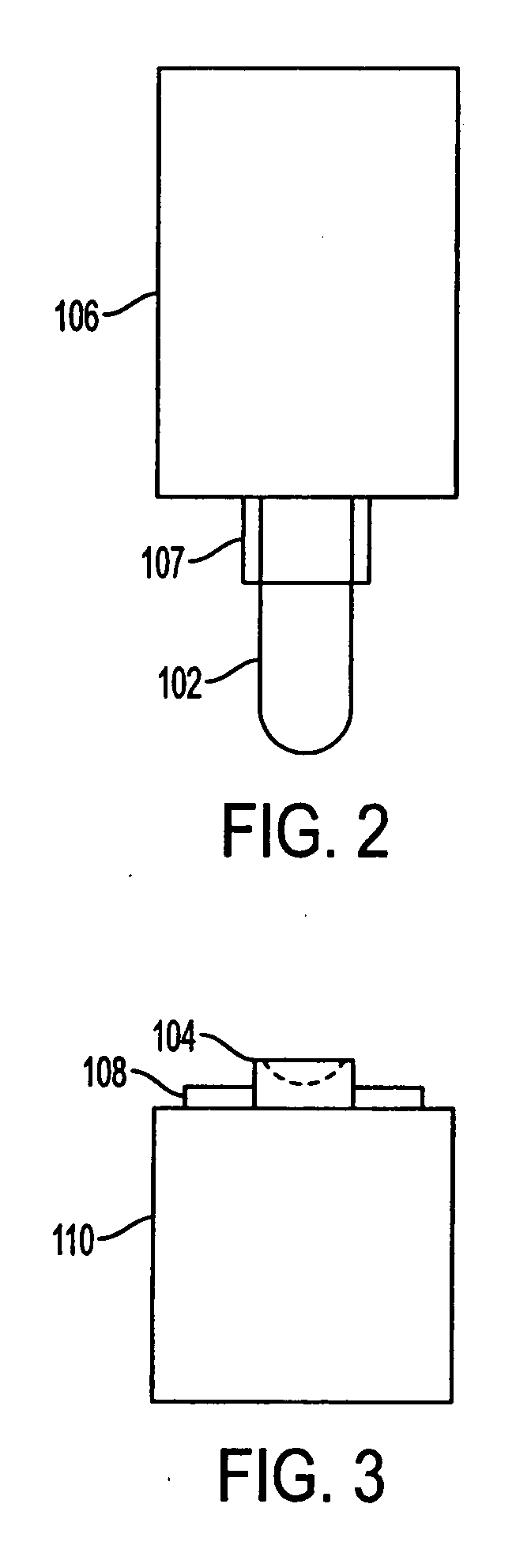

[0040] According to an aspect of the invention, button 104 is placed on seat 108. Seat 108 may be positioned on and attached to seat stage 110. In some embodiments, seat 108 may be movable in one or more axes relative to seat stage 110.

[0041] According to an aspect of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com