Magnetorheological-elastomer-based parallel power control device

A magnetorheological elastomer and control device technology, applied in the field of vector force control, can solve problems such as limiting the application range of machine tools and inability to form, and achieve the effects of improving surface quality and increasing overall stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

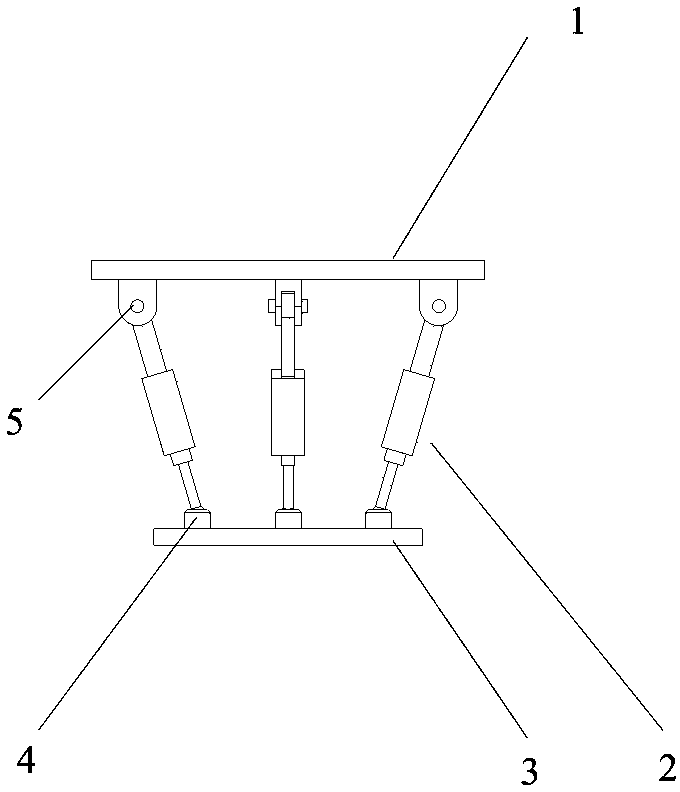

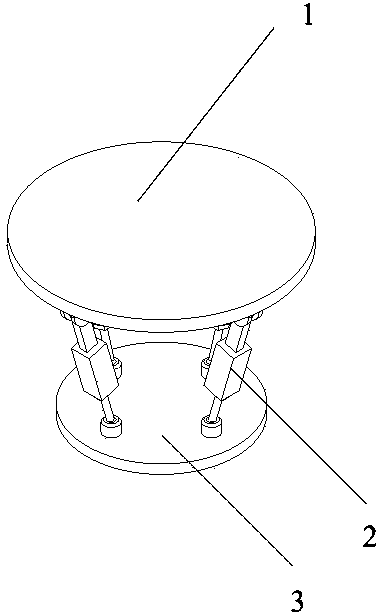

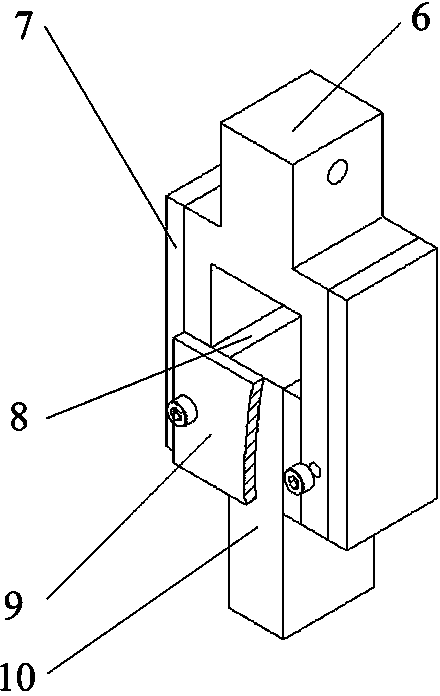

[0017] Parallel force control device based on magnetorheological elastomers, see Figure 1 to Figure 4 , which includes an upper connecting plate 1 and a lower connecting plate 3, four shearing pressure control mechanisms 2 are arranged in the middle cavity of the upper connecting plate 1 and the lower connecting plate 3, and the four shearing pressure control mechanisms 2 are evenly distributed In the middle cavity, each shear-type pressure control mechanism 2 corresponds to the outer part of the corresponding circular surface connected to the upper connecting plate 1 and the lower connecting plate 3 respectively, and the shearing-type pressure control mechanism 2 specifically includes an upper bracket 6, a shearing Block 8, lower bracket 10, electromagnet 7, upper bracket 6 and upper connecting plate 1 are connected by rotating hinge 5, lower bracket 10 and lower connecting plate 3 are connected by ball hinge 4, and the upper part of lower bracket 10 is inserted into the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com