Chipless wood polishing device

A wood and cylinder technology, applied in the field of chip-free wood grinding devices, can solve problems such as low efficiency, and achieve the effects of reducing production costs, high grinding quality and high grinding efficiency

Pending Publication Date: 2018-09-18

重庆草衣木食文化传播有限公司

View PDF5 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

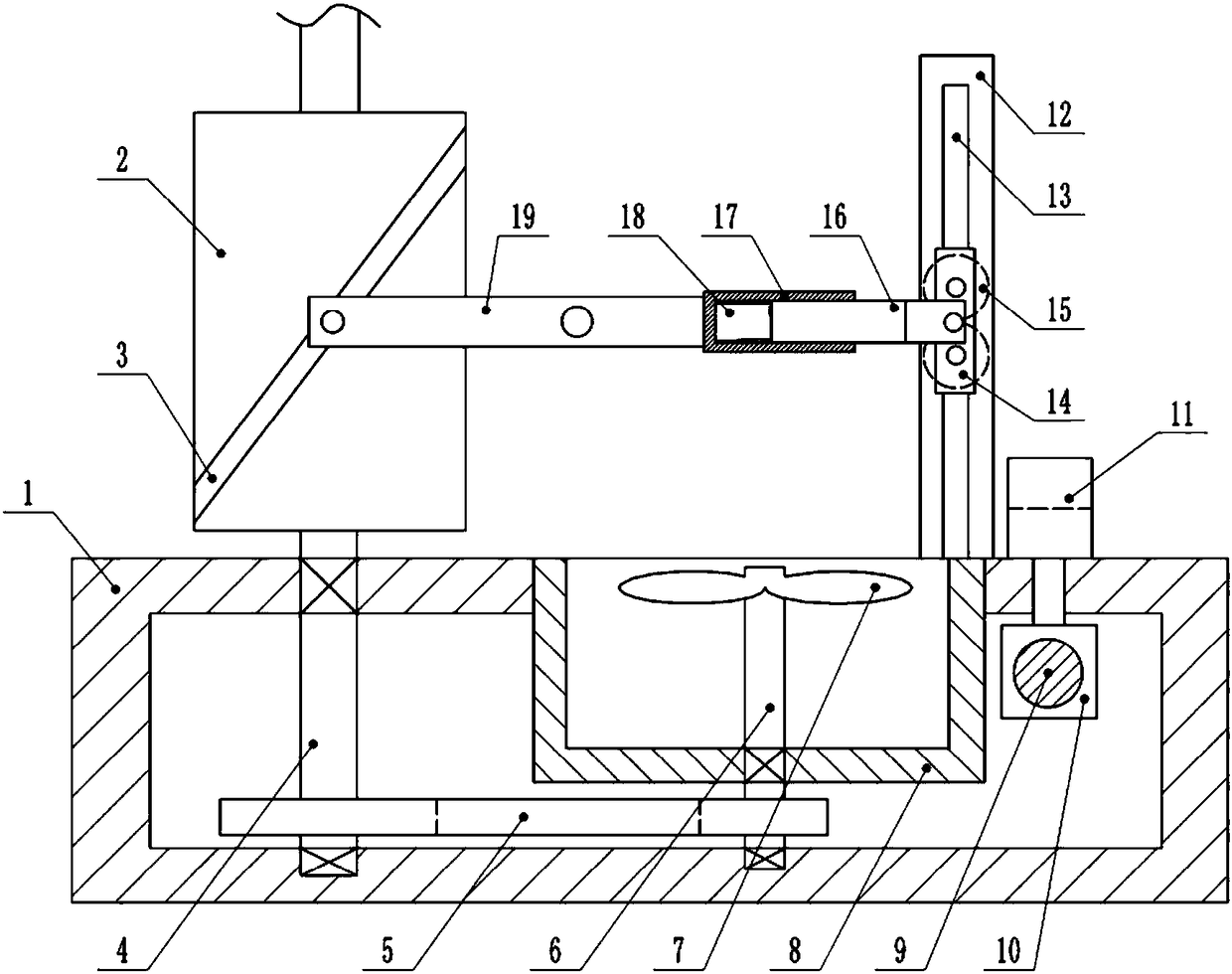

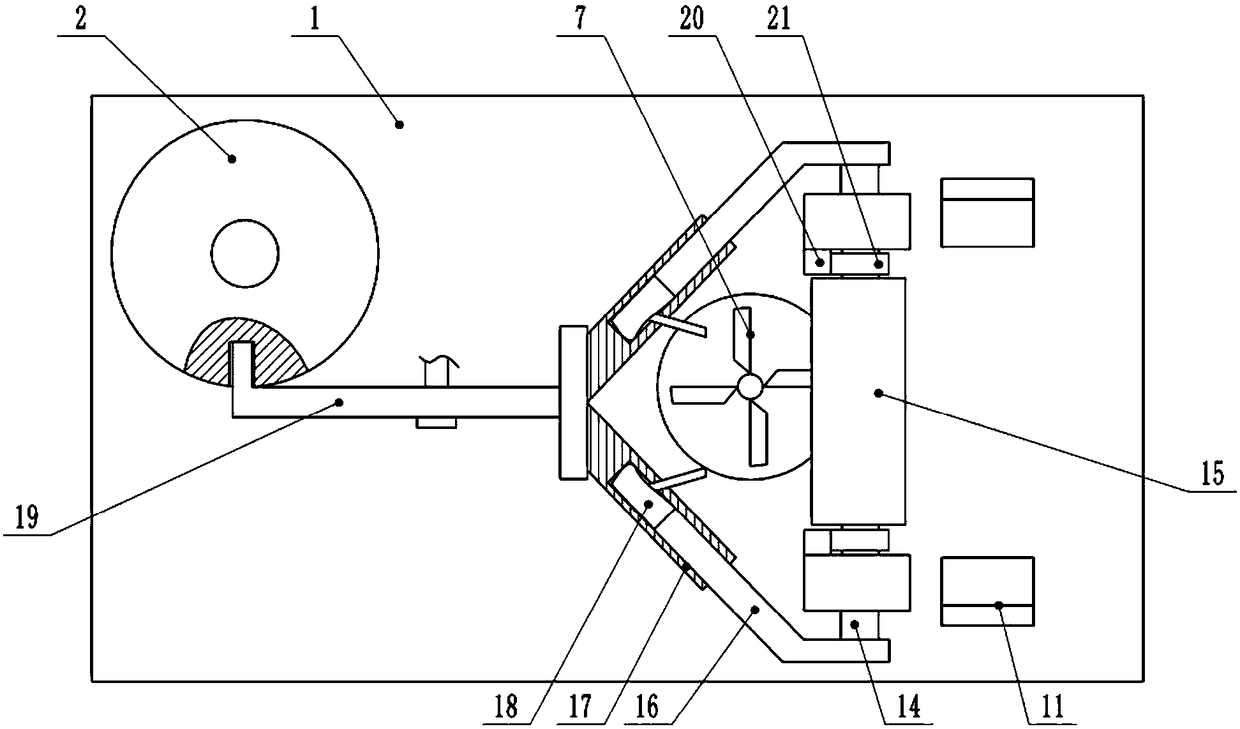

The invention belongs to the technical field of wood processing equipment, and particularly discloses a chipless wood polishing device. The chipless wood polishing device comprises a workbench. A cylinder is rotationally arranged on the workbench. A collection box is arranged on the right side of the cylinder. An impeller is arranged in the collection box and connected with the cylinder through atransmission mechanism. A clamping mechanism for clamping wood is arranged on the workbench. Two supporting plates are arranged on the right side of the collection box. Sliding cavities are formed inthe middles of the two supporting plates correspondingly. Sliding blocks slide in the two sliding cavities correspondingly. A rough polishing roller and a fine polishing roller are rotationally connected between the two sliding blocks. Racks are fixedly connected with the supporting plates. Gears are fixedly connected with the ends of the rough polishing roller and the ends of the fine polishing roller correspondingly. A curved sliding groove is formed in the round face of the cylinder. An oscillating bar is hinged between the cylinder and the supporting plates. The cylinder rotates to drive the oscillating bar to reciprocally swing through the curved sliding groove. Two telescopic rods are fixedly connected with the right end of the oscillating bar. The right ends of the two telescopic rods are hinged to the two sliding blocks correspondingly. According to the scheme, the polishing efficiency is high, and collection treatment on chips is achieved.

Description

technical field [0001] The invention belongs to the technical field of wood processing equipment, and in particular relates to a chipless wood grinding device. Background technique [0002] Furniture refers to a class of utensils that are indispensable for human beings to maintain normal life, engage in production practices and carry out social activities. Furniture also follows the footsteps of the times and continues to develop and innovate. Up to now, there are many categories, different materials, complete varieties, and different uses. Since furniture is designed and produced to meet people's certain material needs and use purposes, furniture also has factors in terms of materials and appearance. Furniture is made of various materials through a series of technological processes, and materials are the material basis of furniture. At present, the main materials of furniture include wood, metal, plastic, rattan, bamboo, glass, etc., and in existing furniture, wood is gen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B24B19/24B24B27/00B24B41/06B24B47/12B24B55/12B24B41/02B08B5/02

CPCB08B5/02B24B19/24B24B27/0076B24B41/02B24B41/06B24B47/12B24B55/12

Inventor 朱培钢

Owner 重庆草衣木食文化传播有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com