Electrical terminal ground structure and installation method

An electrical terminal and grounding structure technology, applied in the field of electrical terminal grounding structure, can solve the problems of unstable conductivity, inconvenient disassembly and maintenance, and difficult connection between electrical terminals and composite materials, and achieves grounding performance against pull-off force and meets performance requirements. effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The electrical terminal grounding structure of this embodiment is composed as follows:

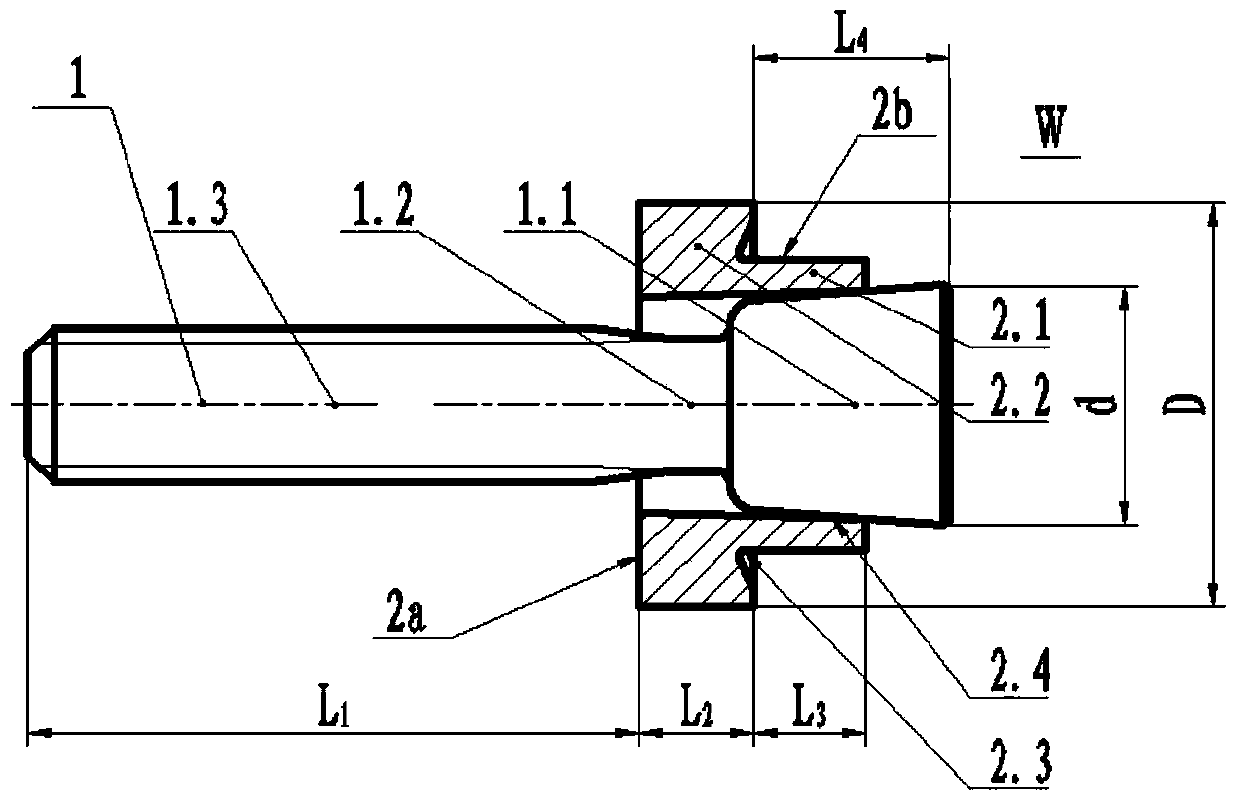

[0034] 1) see figure 1 , set the bolt 1 composed of a wedge-shaped head 1.1 at the front end, a transition polished rod section 1.2 in the middle and a threaded section 1.3 at the rear end, and the material is stainless steel. It is assumed that the collar 2 has a sleeve 2.1 at the front end, a flange 2.2 at the rear end and a groove 2.3 on the front face of the flange, and the material is aluminum alloy or copper alloy. The sleeve is sheathed outside the wedge-shaped head, and the inner hole of the sleeve is a wedge-shaped surface 2.4 with the same inclination as the wedge-shaped head.

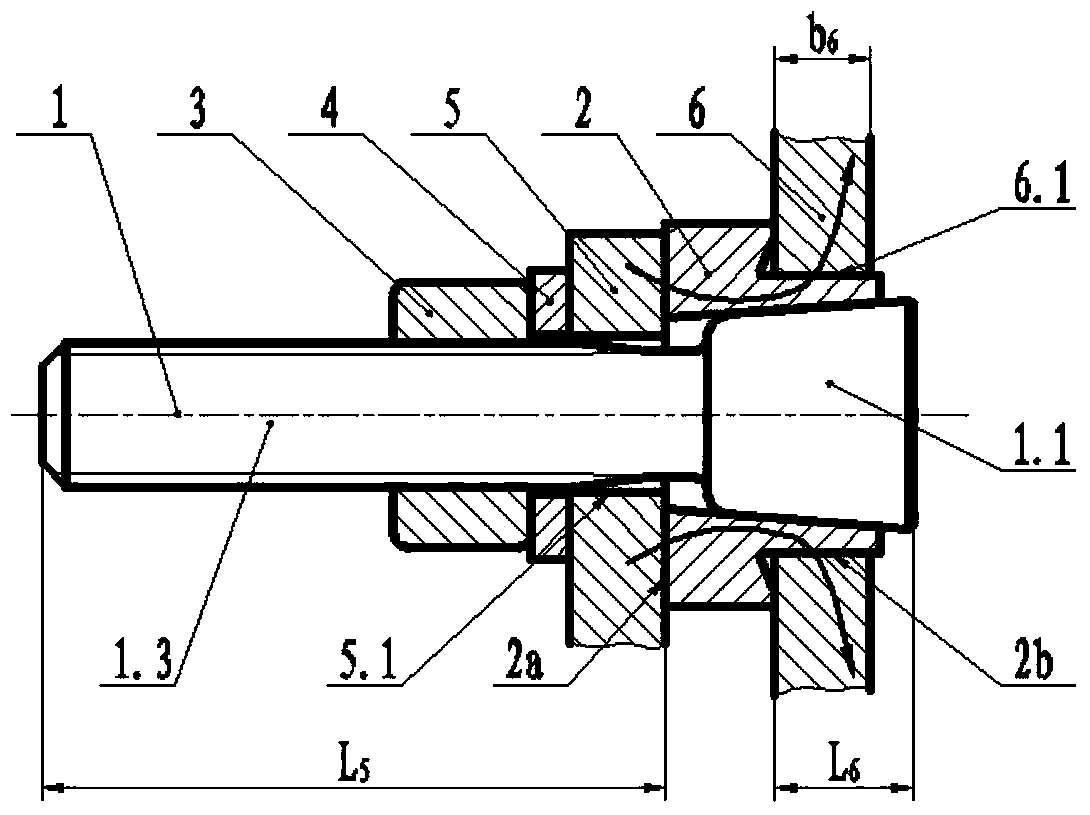

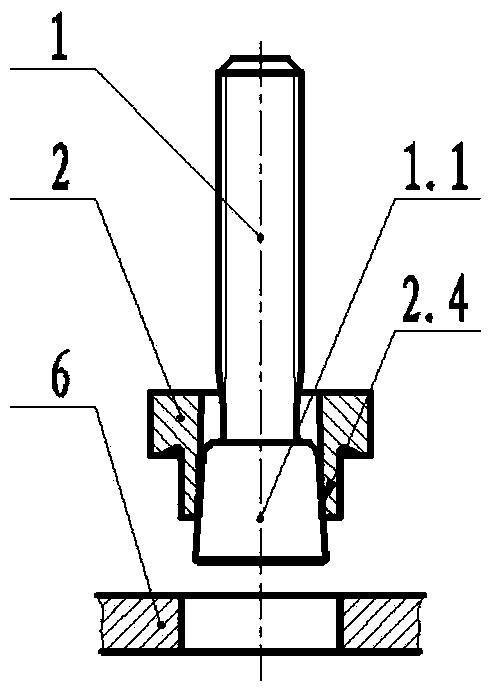

[0035] 2) see figure 2 , The outer circular surface 2b of the sleeve is placed in the mounting hole 6.1 of the grounding plate 6; the wedge-shaped head 1.1, the sleeve 2.1 and the mounting hole 6.1 are radially tightly fitted.

[0036] 3) see figure 2 , the electrical terminal 5 is set outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com