Explosion arrestment flap valve

A flap valve and explosion-proof technology, which is applied to valve details, safety valves, balance valves, etc., can solve the problems of being easily deformed by impact, increasing equipment maintenance costs, and poor sealing effects, so as to prolong the service life and benefit Action and sealing, close contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail in conjunction with specific inventions below.

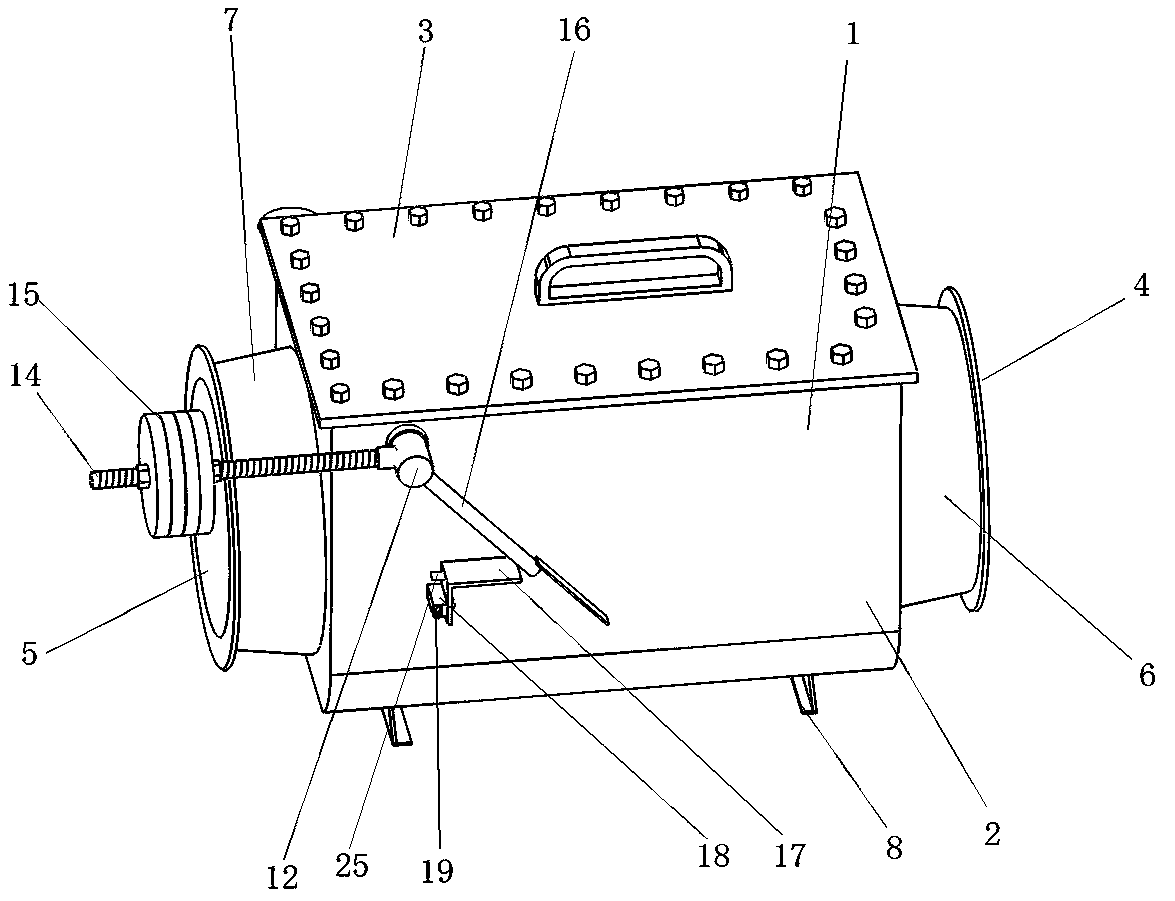

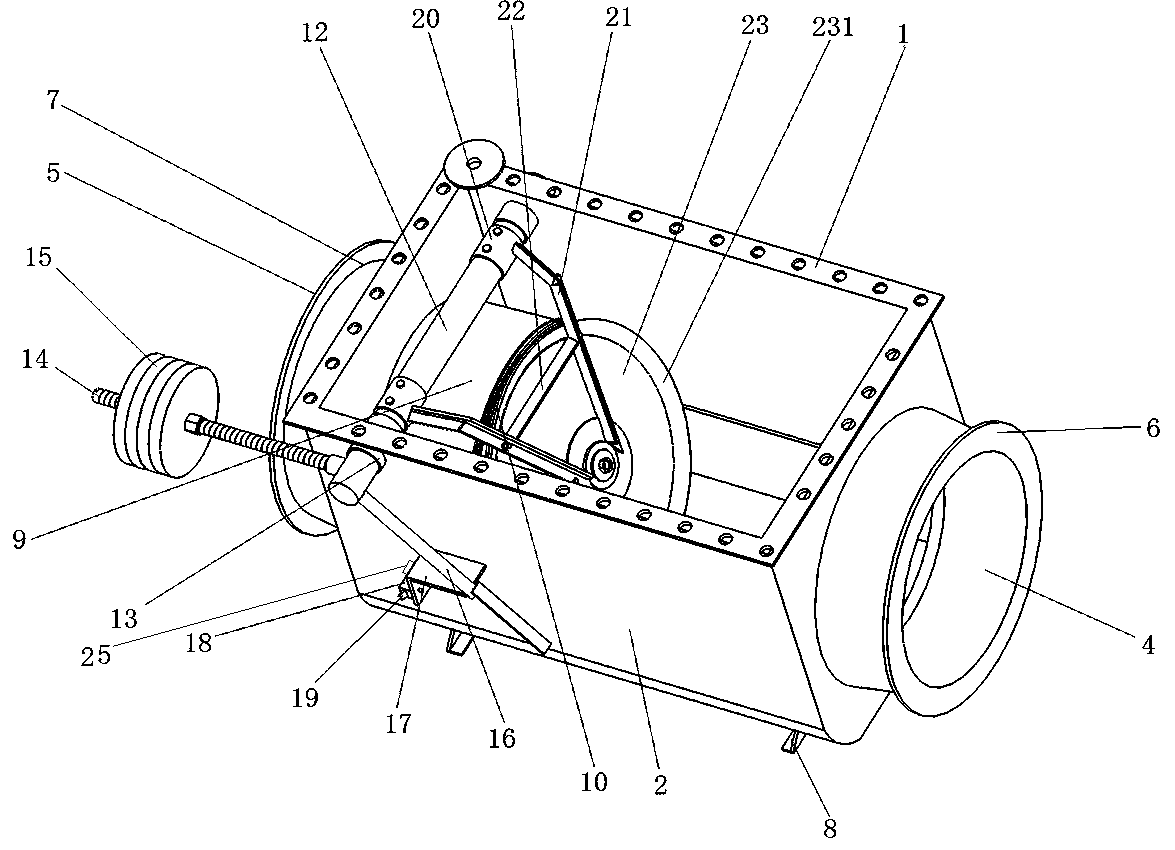

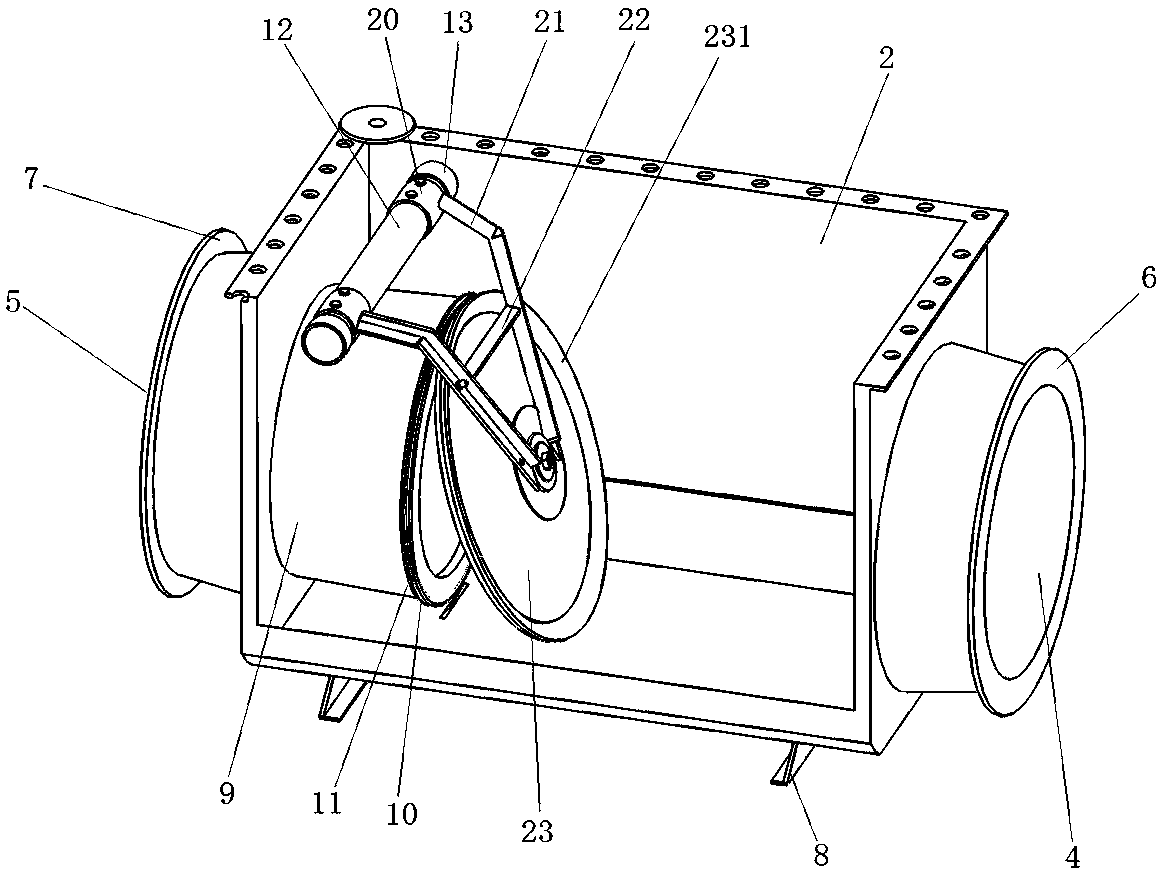

[0028] A flameproof flap valve, combined with Figure 1 to Figure 8 As shown, it includes a valve body 1, an air inlet 5, an air outlet 4, and an explosion-proof mechanism.

[0029] The valve body 1 includes a valve housing 2 and a valve cover 3 . The valve housing 2 is a rectangular upper part and a semi-cylindrical lower part. The top of the valve housing 2 is provided with a rectangular opening, and is fixedly provided with an outer edge. The top array of the outer edge is provided with a plurality of threaded holes. The bonnet 3 is arranged above the valve casing 2 for sealing the valve body 1. The bonnet 3 is provided with a threaded hole corresponding to the threaded hole on the top of the valve casing 2. The bonnet 3 and the valve casing 2 are fixedly connected by bolts. The bottom end of the valve casing 2 is fixedly provided with two supports 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com