Annular diamond double-blade band saw and manufacturing method thereof

A production method and diamond technology, applied in the direction of metal sawing equipment, sawing machine tool manufacturing, tool manufacturing, etc., can solve the problems of increased processing costs and production cycles, poor sheet quality, and low cutting efficiency, and achieve guaranteed cutting Stability and directionality, ensuring product stability, and beneficial to flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

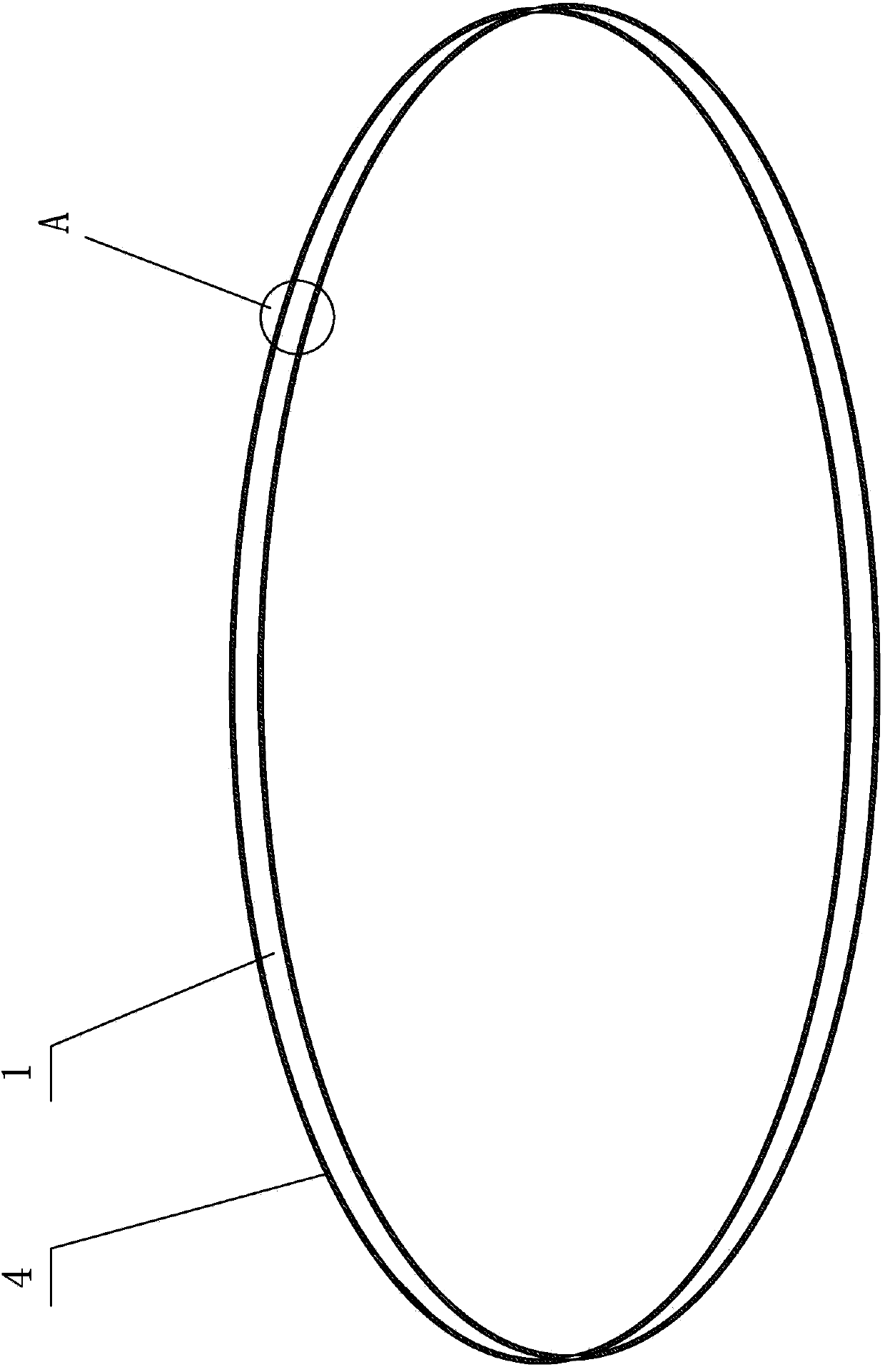

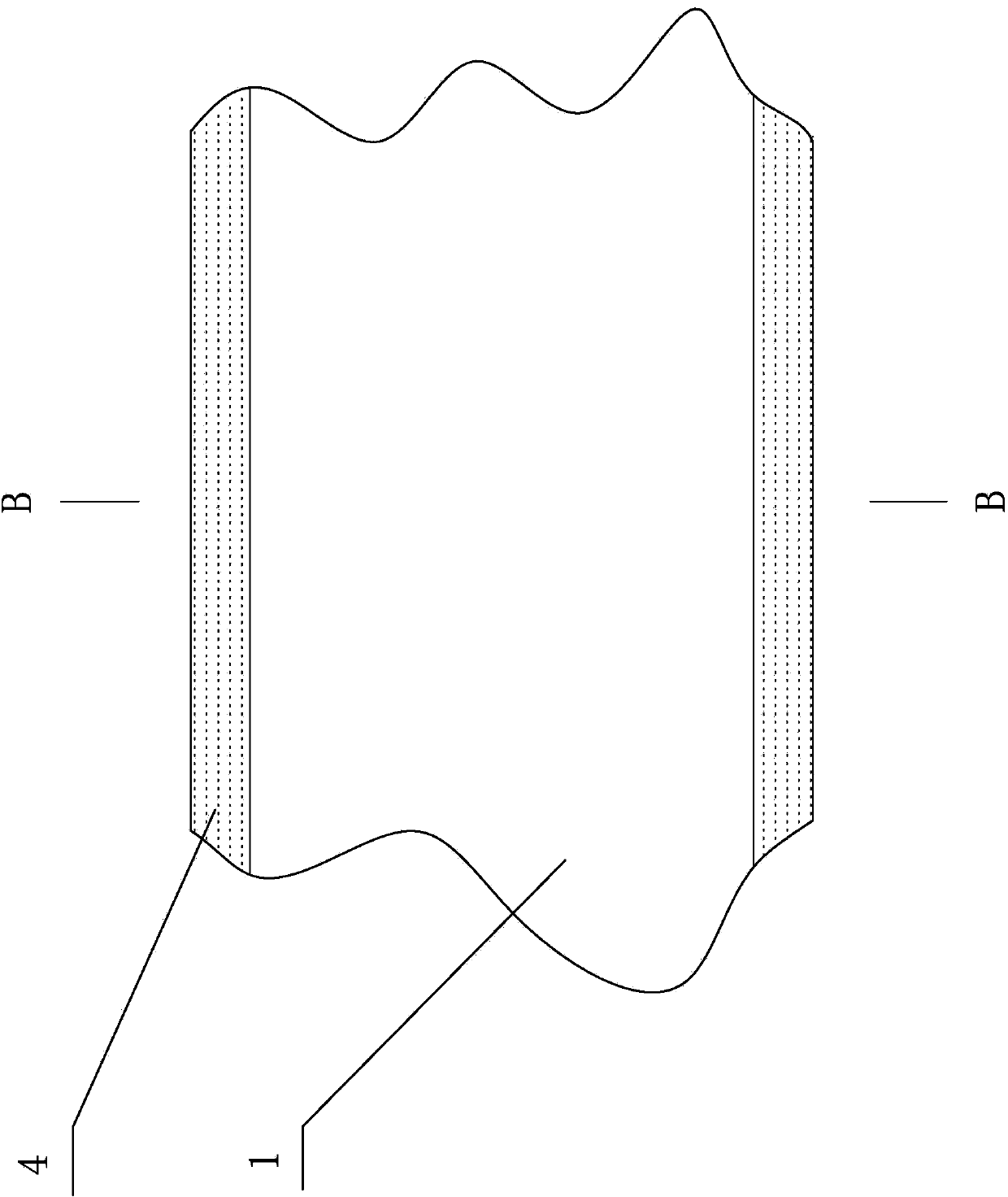

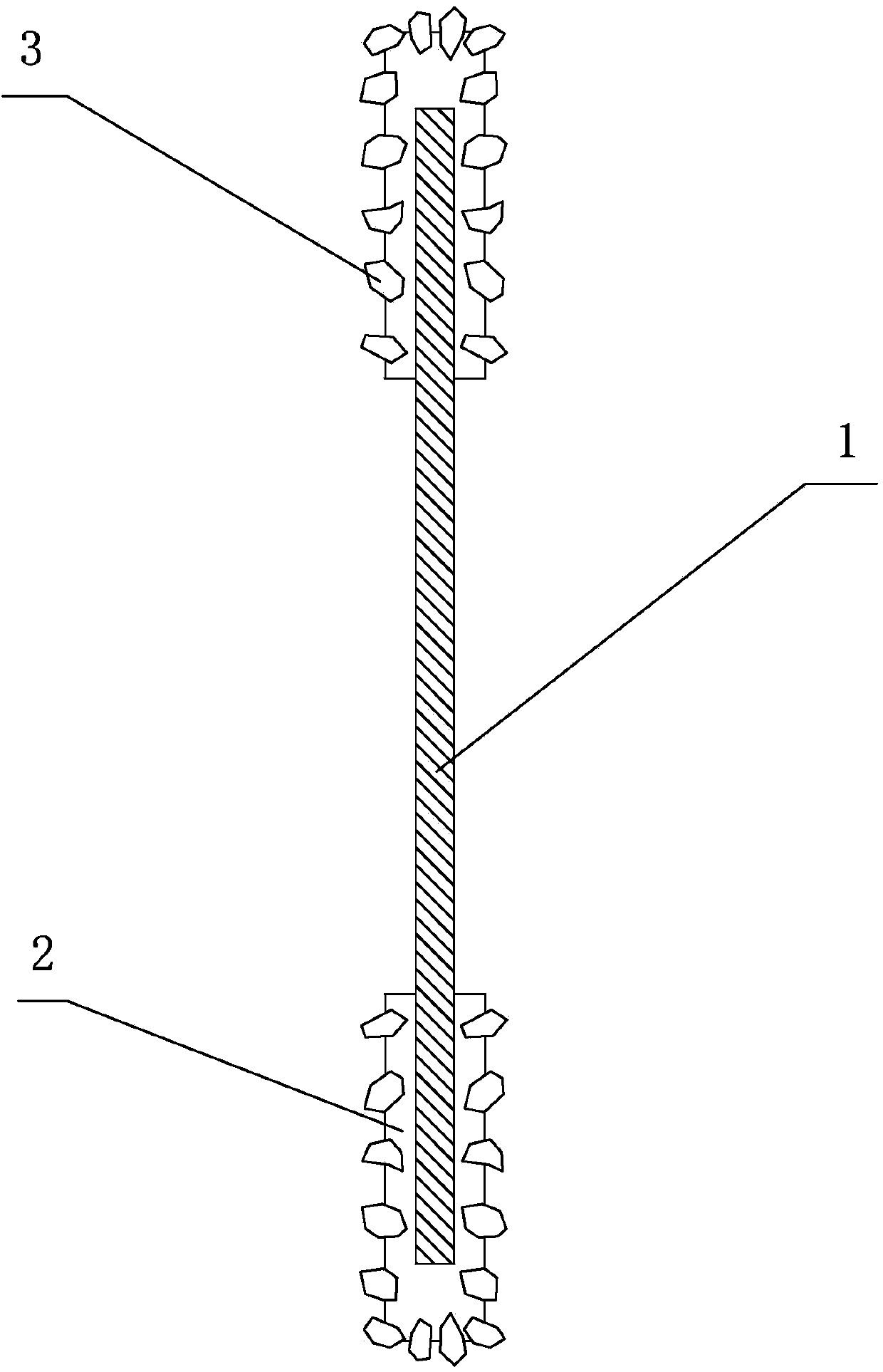

[0034] The main body of the annular diamond double-edged band saw of the present invention is a steel strip 1, the steel strip 1 generally adopts a stainless steel strip with a specification of 3800mm×8mm×0.2mm, and the two ends of the stainless steel strip 1 are welded into a ring; the steel strip 1 Both sides (width direction) and edges of the positive and negative surfaces (inner peripheral surface, outer peripheral surface) are coated with a symmetrical diamond composite coating 4, and the diamond composite coating 4 is along the length direction (circumferential direction) of the steel strip 1. Continuous distribution; the diamond composite coating 4 includes electrodeposited metal layer 2 (nickel or nickel-cobalt alloy) and diamond particles 3, and the diamond particles 3 are uniformly consolidated on the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com