Low-noise gear

A low-noise, gear technology, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of low strength, low noise, and large noise, and achieve high strength, low noise, and low noise small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

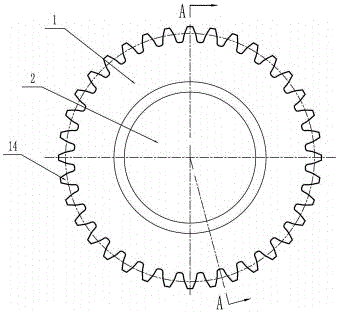

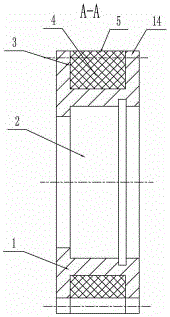

[0014] Such as figure 1 and figure 2 As shown, the gear of the present invention includes a base body 1 made of iron and steel. The base body 1 is provided with a mounting hole 2. The outer peripheral wall of the base body 1 is provided with a circle of first annular grooves 3, and the first annular groove 3 is poured with nylon material. The first annular insert 4 has a plurality of first teeth 14 processed on the outer circumference of the base body 1, and a plurality of second teeth 5 are simultaneously processed on the outer circumference of the first annular insert 4. The tooth 14 and the plurality of second teeth 5 correspond one by one to form a complete tooth.

Embodiment 2

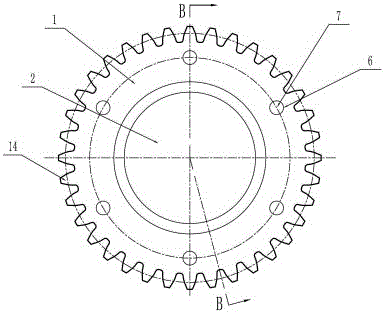

[0016] Such as image 3 and Figure 4 As shown, the gear of the present invention includes a base body 1 made of iron and steel. The base body 1 is provided with a mounting hole 2. The outer peripheral wall of the base body 1 is provided with a circle of first annular grooves 3, and the first annular groove 3 is poured with nylon material. The first annular insert 4, six first through holes 6 communicating with the first annular groove 3 are evenly distributed on the two side walls of the base body 1, and the first through holes 6 are poured with a first insert 7 made of nylon material , the first insert 7 and the first annular insert 4 are an integral structure, a plurality of first teeth 14 are processed on the outer circumference of the base body 1, and multiple teeth 14 are processed on the outer circumference of the first annular insert 4 simultaneously. A second tooth 5, a plurality of first teeth 14 and a plurality of second teeth 5 form a complete tooth in one-to-one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com