Large-radial-force supporting shaft flow distribution cycloid hydraulic motor

A technology of cycloidal hydraulic motor and supporting shaft, which is applied in the direction of rotary or swing piston engine, rotary piston engine, machine/engine, etc., to achieve simple structure, solve rigidity and reliability, radial and axial force bearing capacity strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

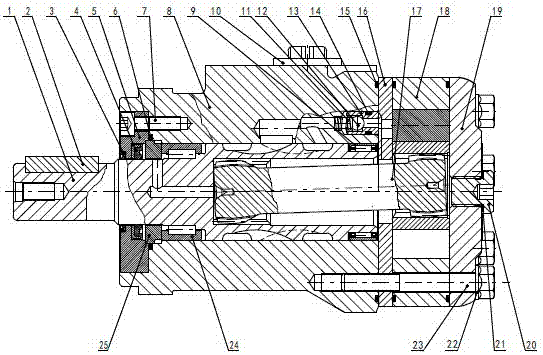

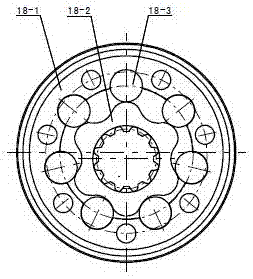

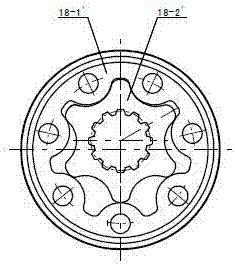

[0022] The basic composition of a large radial force supporting shaft distribution cycloidal hydraulic motor in this embodiment can be found in figure 1 As shown, combined with the above figure 1 Examples, the present invention is described in detail as follows. A large radial force supporting shaft distribution cycloidal hydraulic motor in this embodiment has an SAE A-type standard Φ82.55 installation notch or a close-to-size installation notch, and a body shell 8 with a mounting flange surface, which is placed on the body shell The output shaft 1 structure of the torque output in 8, and the rotor stator pair fixedly connected with the body shell 8 by connecting bolts 23, the flow distribution system and the flow channel for the oil to enter and exit the motor cavity and the rear cover 19, through the high and low pressure oil The liquid enters and exits the flow path of the inner cavity of the motor to the stator pair 18 to generate torque, which is transmitted to the outpu...

Embodiment 2

[0030] This embodiment uses Figure 5 In the first embodiment of structure replacement figure 1 The structure of the front cover 5, Figure 5 It is an installation surface intention of front cover 5' in embodiment two, and Image 6 for Figure 5From the schematic diagram of the front cover 5', it can be seen that the front cover 5' is nested in the circular surface of the positioning spigot of the body shell 9. A front cover 5' is provided, said front cover 5' being provided with a rotary shaft seal 4. The cylindrical head installation hole of the screw 7 of the front cover 5' is a milled semicircular opening structure, the cylindrical head of the screw 7 is completely installed on the front cover 5', and the ingenious design of the front cover 5' ensures the reliable installation of the motor positioning notch .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com