Movable steel arch bracing trolley

A steel arch, mobile technology, applied in the direction of wheels, vehicle parts, shaft lining, etc., can solve the problems of increasing the installation process of steel arch support equipment, increasing labor intensity, high risk, etc., and achieves a simple drive control system High efficiency, improved reliability and stability, and good ground adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

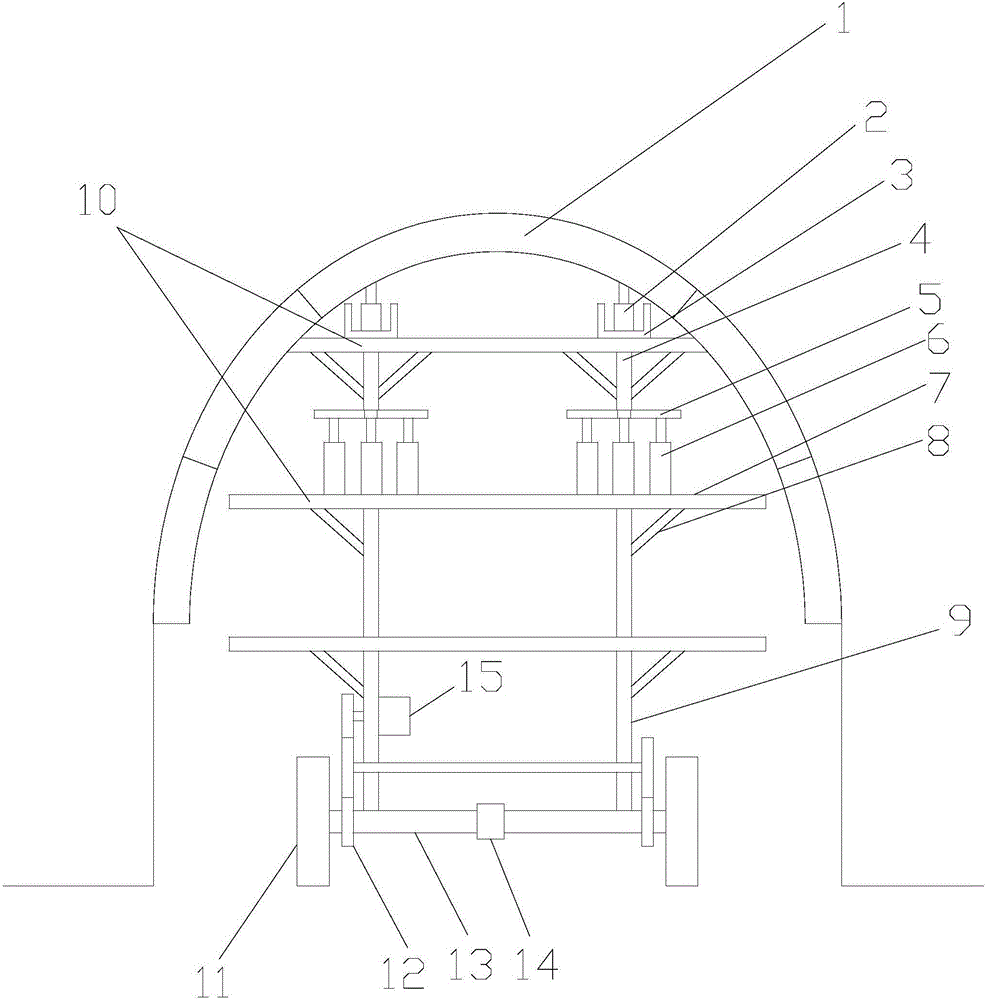

[0017] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, the movable steel arch 1 of the present embodiment supports the trolley, including the lower bracket 9, the upper bracket 4, and the deformation for supporting the lower bracket 9 and driving the lower bracket 9 to move. Wheel 11 and steel arch 1 jacking system; said steel arch 1 jacking system includes a jack group I6 arranged between the lower bracket 9 and the upper bracket 4 for jacking up the upper bracket 4 and a jack set on the top of the upper bracket 4 The jack group II2 for lifting the steel arch 1; the jack group I6 and the jack group II2 both include one or more jacks; in this embodiment, the upper bracket 4 and the lower bracket 9 include cross bars 10, columns and A chute 3 arranged longitudinally is fixed on the cross bar 10 of the inclined strut 8 and the upper bracket 4, and the jack group II 2 can be arranged in the chute 3 to facilitate the movement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com