Modular vibratory pile driver system

a technology of pile driver and module, which is applied in the direction of bulkhead/pile, construction, foundation engineering, etc., can solve the problems of significant increase in cost on the job site, and achieve the effects of reducing costs, saving time, and facilitating the driving of different types of piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

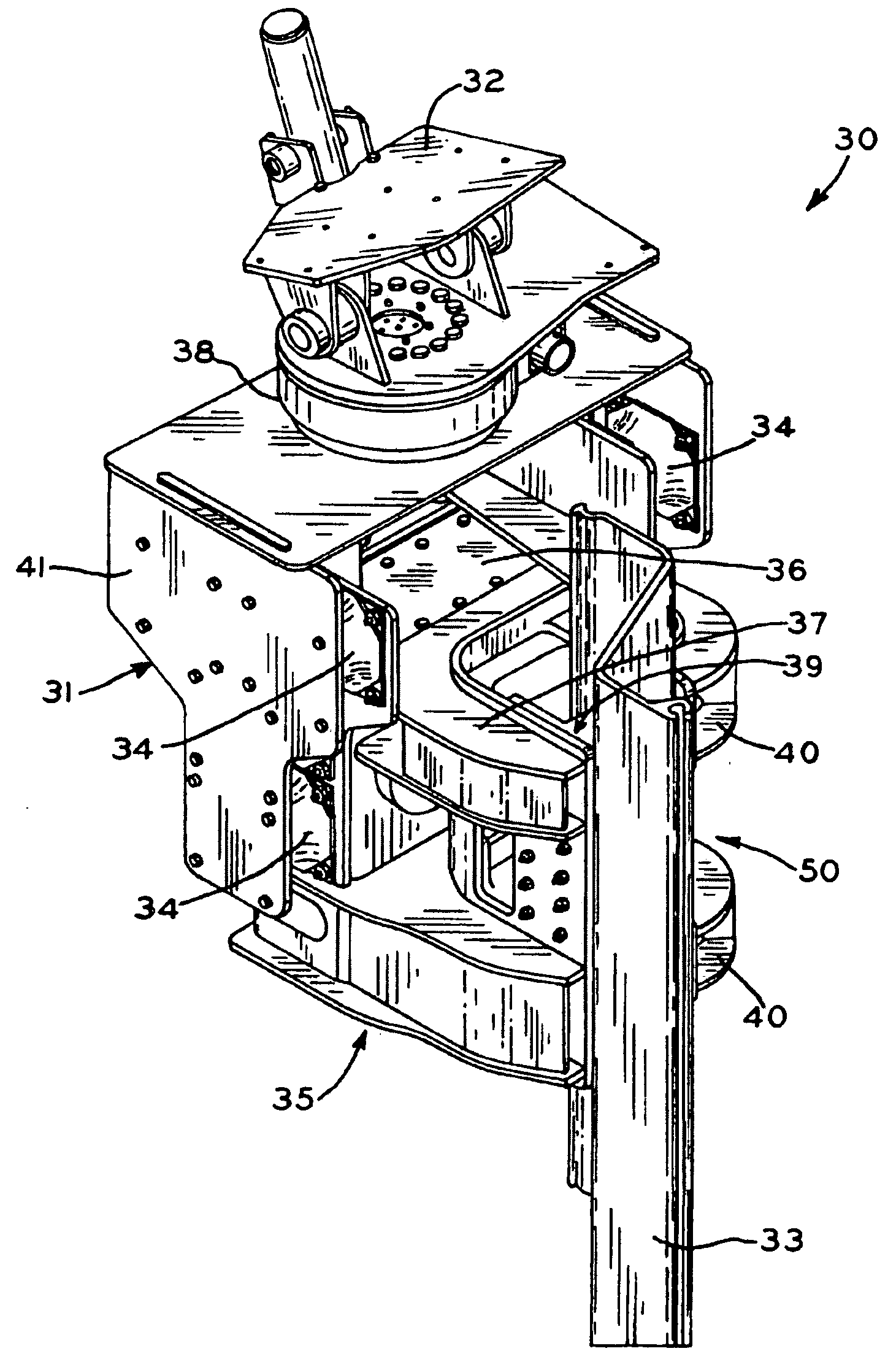

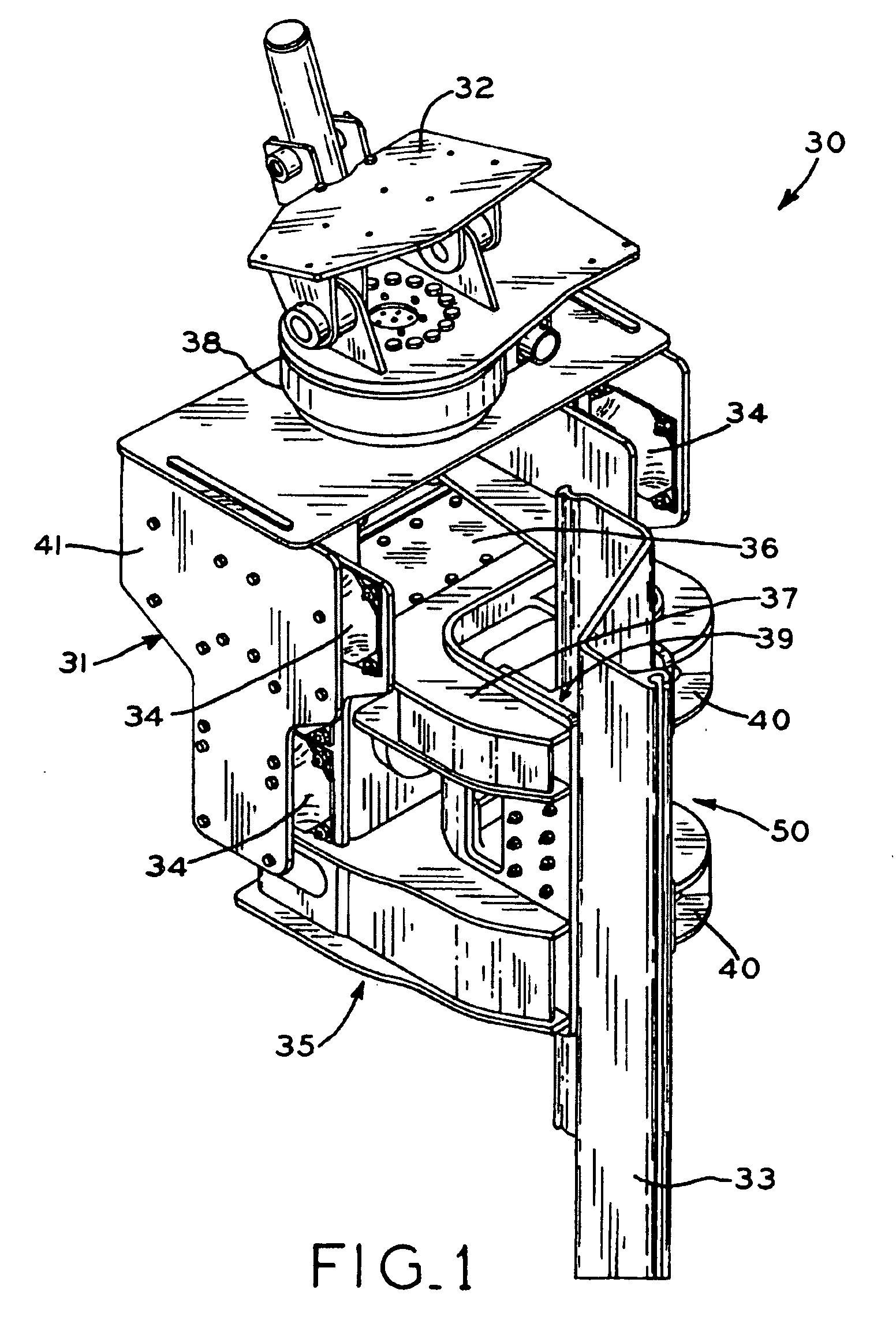

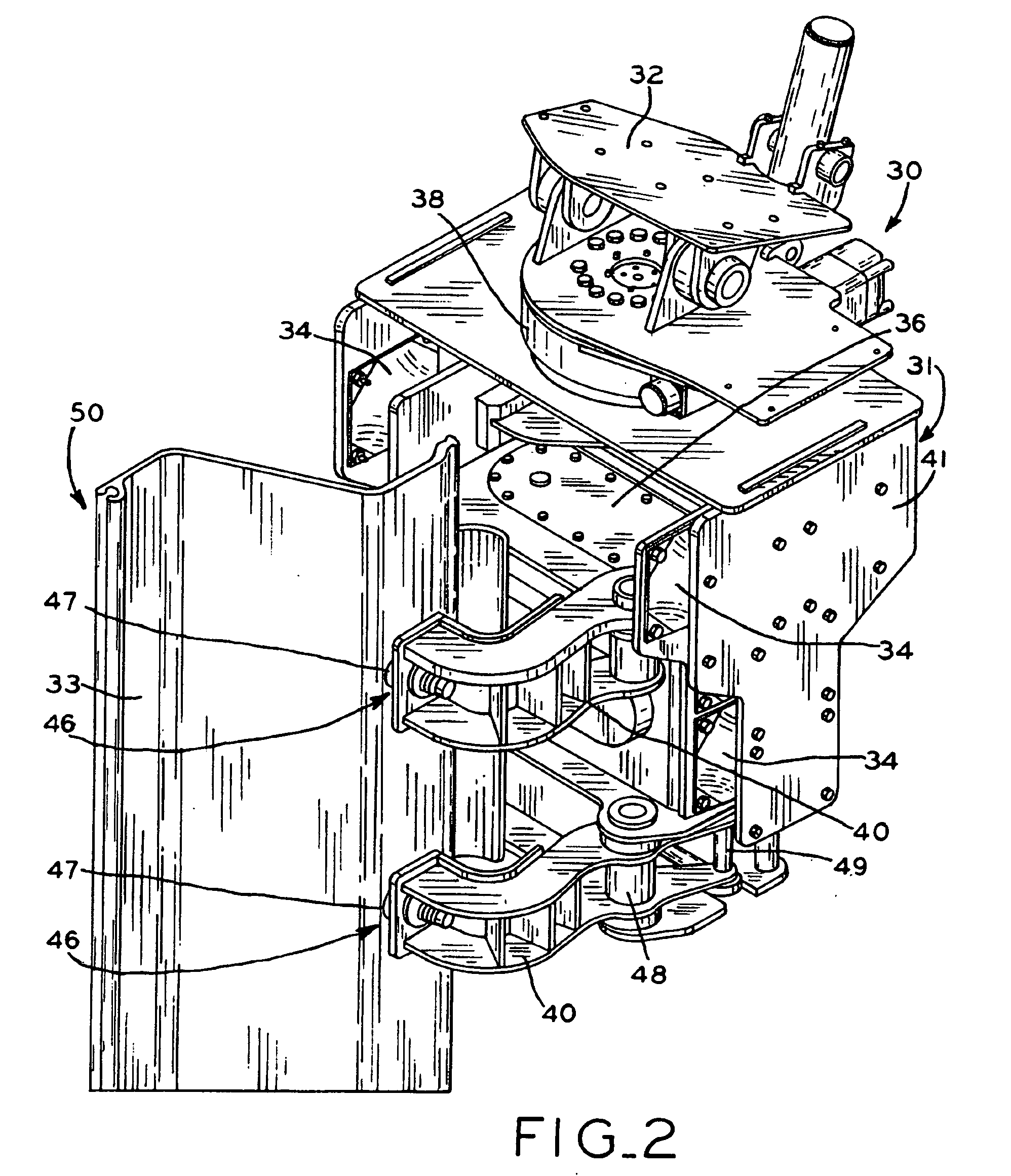

[0031]Referring now to FIGS. 1-5, modular vibratory side grip pile driver 30 is shown and generally includes housing 31, first assembly 35, and jaw assembly 50. Pile driver 30 may be used to grasp and drive sheet or beam, e.g., I-beam and H-beam, pile 33 into the ground. Housing 31 includes vibratory gear case 36 and mounting base 37. Bracket 41 connects housing 31 to attachment assembly 32 which is used to attach pile driver 30 to an excavator or other suitable construction machine for mounting pile driver 30 thereon. Rotational connector 38 is provided along with attachment plate 32 to permit rotation of housing 31 relative to the excavator. Rubber insulators 34 are included on the inner portions of housing 31 to reduce vibration caused by gear case 36 during use of pile driver 30 and to prevent such vibration from vibrating a portion of the excavator. Pile driver 30 is a modification of the Model SPM 15 vibratory pile driver manufactured by Hercules Machinery Corporation of Fort ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com