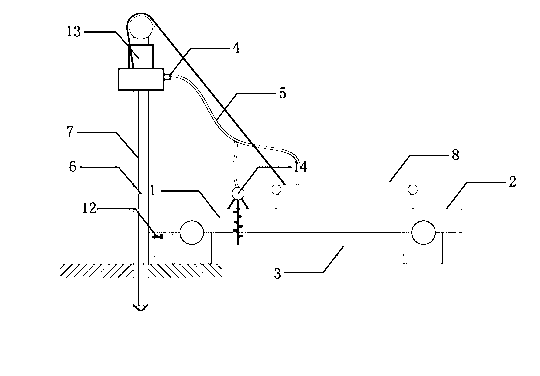

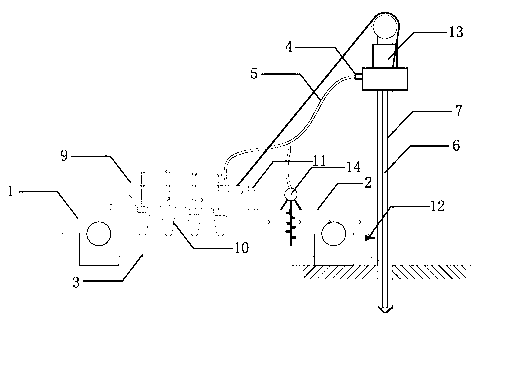

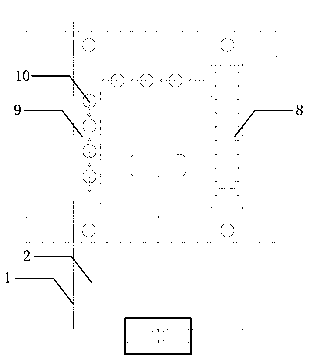

Construction equipment of hole drilling/punching cast-in-place pile with self-provided mud pit and mud separating device

A technology of mud separation and construction equipment, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., to achieve the effects of strong rock-socketing ability, easy control of construction costs, and low cost of pile foundations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0031] Project name: Lianyungang Youth Pioneer Building Lianyungang Kuge Real Estate Development Co., Ltd.

[0032] Project Location: Intersection of Huanghai Avenue and Huaguoshan Avenue in Lianyungang

[0033] Project overview: The building is 100 meters high, the pile is about 50 meters long, 160 bored and punched cast-in-place piles are designed, the end of the pile is 50 cm of medium weathered gneiss, the upper part of the pile foundation is 14-16 meters of silt, and 12 -16 meters, the lower part of the silt is 20 meters, the construction site has no hardening treatment, and the self-contained mud drilling (punching) mechanical equipment and methods are used for construction. First make 4 test piles, complete in 4 days, one pile per day, the bearing capacity of a single pile is 9600KN, the maximum sinking amount after static load field test is within 20mm, which belongs to end piles, and each pile driver for engineering pile construction is greater than One, after the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com