Pile extractor and construction method for pile extraction

A technology of pile extractor and sinking pile, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., and can solve the problems of no pile extractor equipment, exceeding compressive strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

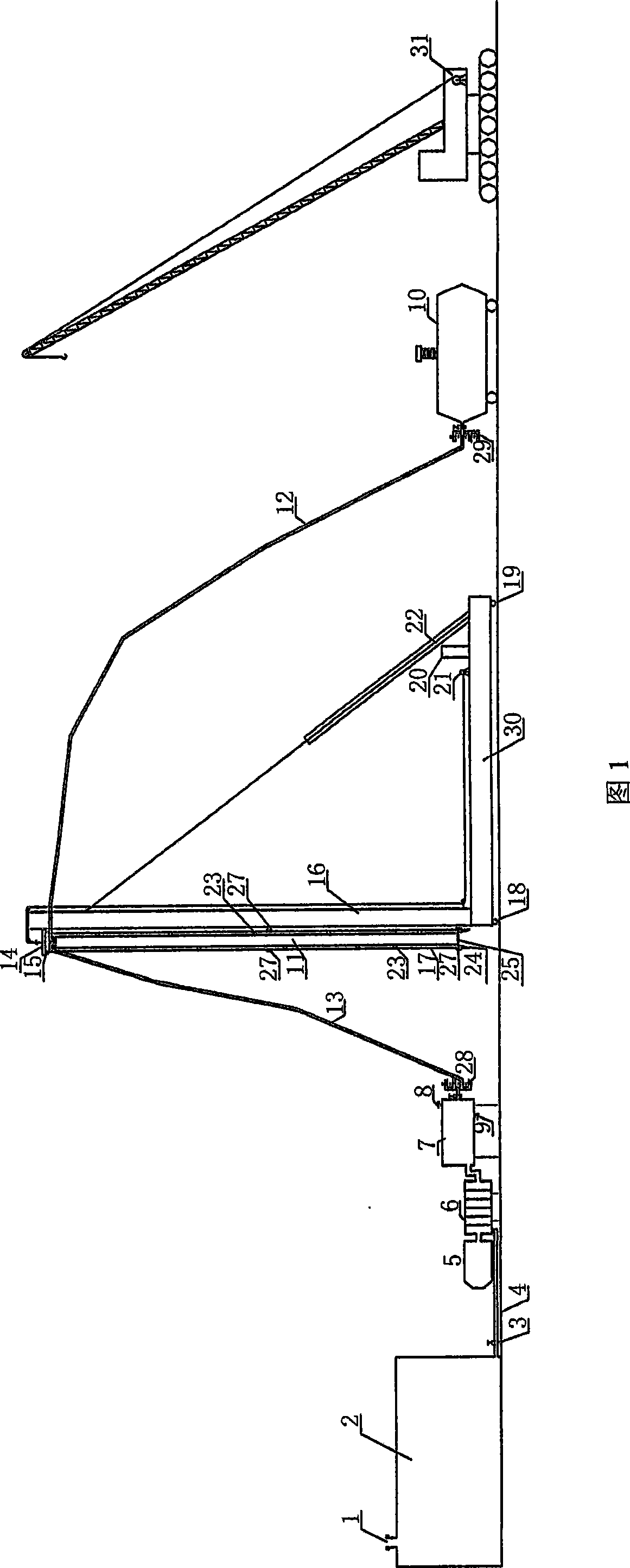

[0037] Embodiment 1——I type pile extractor

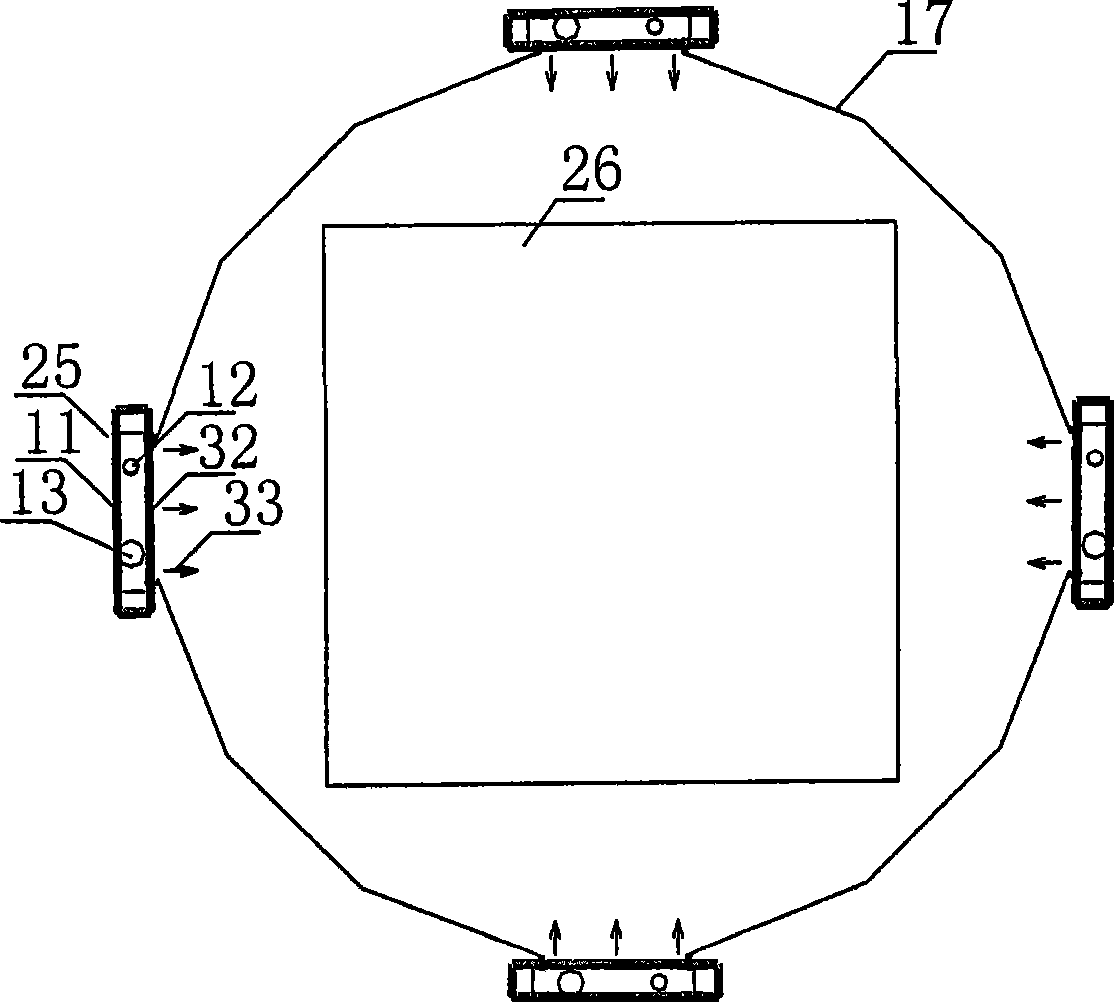

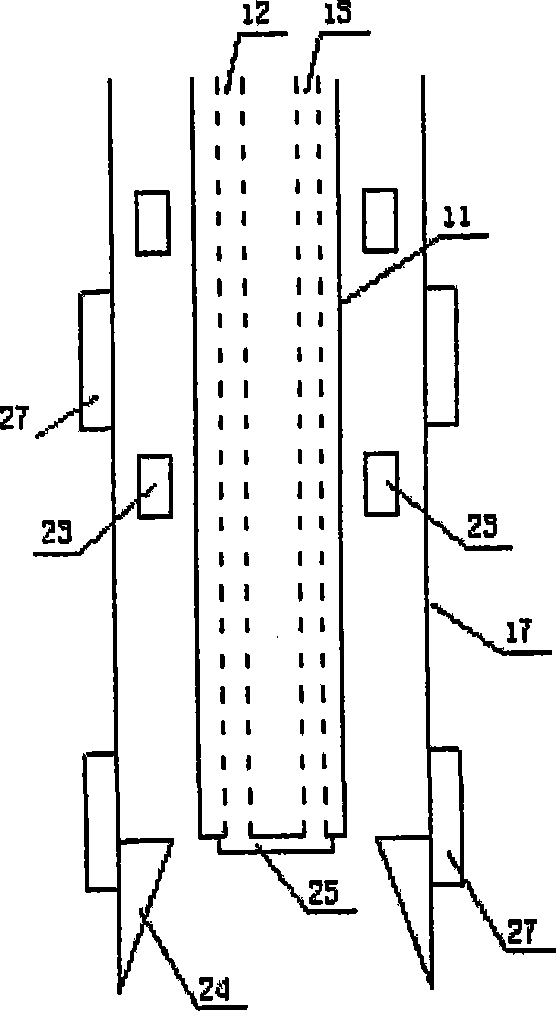

[0038] ①Use a spiral pipe with a wall thickness of 10 mm to form a casing 17 that is longer than the length of the pile 26 to be pulled out. Cut a number of surface holes 23 with a side length of 7 cm on the surface of the casing. 17. The diameter exceeds the diagonal length of the pulled pile 26 by 15cm;

[0039] 2. four flushing pipes 12 and four flushing pipes 13 made of rubber, with a diameter of 5 cm and a wall thickness of 5 mm are arranged outside the sleeve pipe 17, wherein each of them is a group of one flushing pipe 12 and one flushing pipe 13. The outside is covered with channel steel protective sleeves 11, and four protective sleeves 11 are symmetrically distributed in a cross shape outside the casing 17;

[0040]The four flushing pipes 12 and the flushing pipes 13 at the top of the four protective sleeves 11 are respectively connected with the four external flushing pipes 12 and the flushing pipes 13 through hollow bol...

Embodiment 2

[0049] Embodiment 2, utilize I type pile extractor to carry out the construction method of pile extraction, and its construction steps are as follows:

[0050] ①Break the cap to expose the 26 pile heads to be pulled out;

[0051] ②Bury a steel casing with a diameter of 17.40cm larger than the casing at the position of 26 piles to be pulled, and backfill and compact all the soil around the steel casing to ensure that the Type I pile puller does not sink during construction;

[0052] ③Open the control box 20 of the DZ90 vibrating pipe sinking pile machine, hang the casing system to the pile head of the pulled pile 26 with the hoist 21, adjust the hoist 21, and ensure that the center line of the casing 17 and the center line of the pulled pile 26 are on the same line on a straight line;

[0053] ④Start the vibratory hammer 14 of the DZ90 vibratory pipe sinking pile machine to ensure that the exciting force of the vibratory hammer 14 is greater than the resistance when the sinkin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com