Construction method and device for guide displacement pressure precast pile

A technology of construction device and prefabricated pile, which is applied to earth-moving drilling, driving device for drilling in wellbore, sheet pile wall, etc. The effect of speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

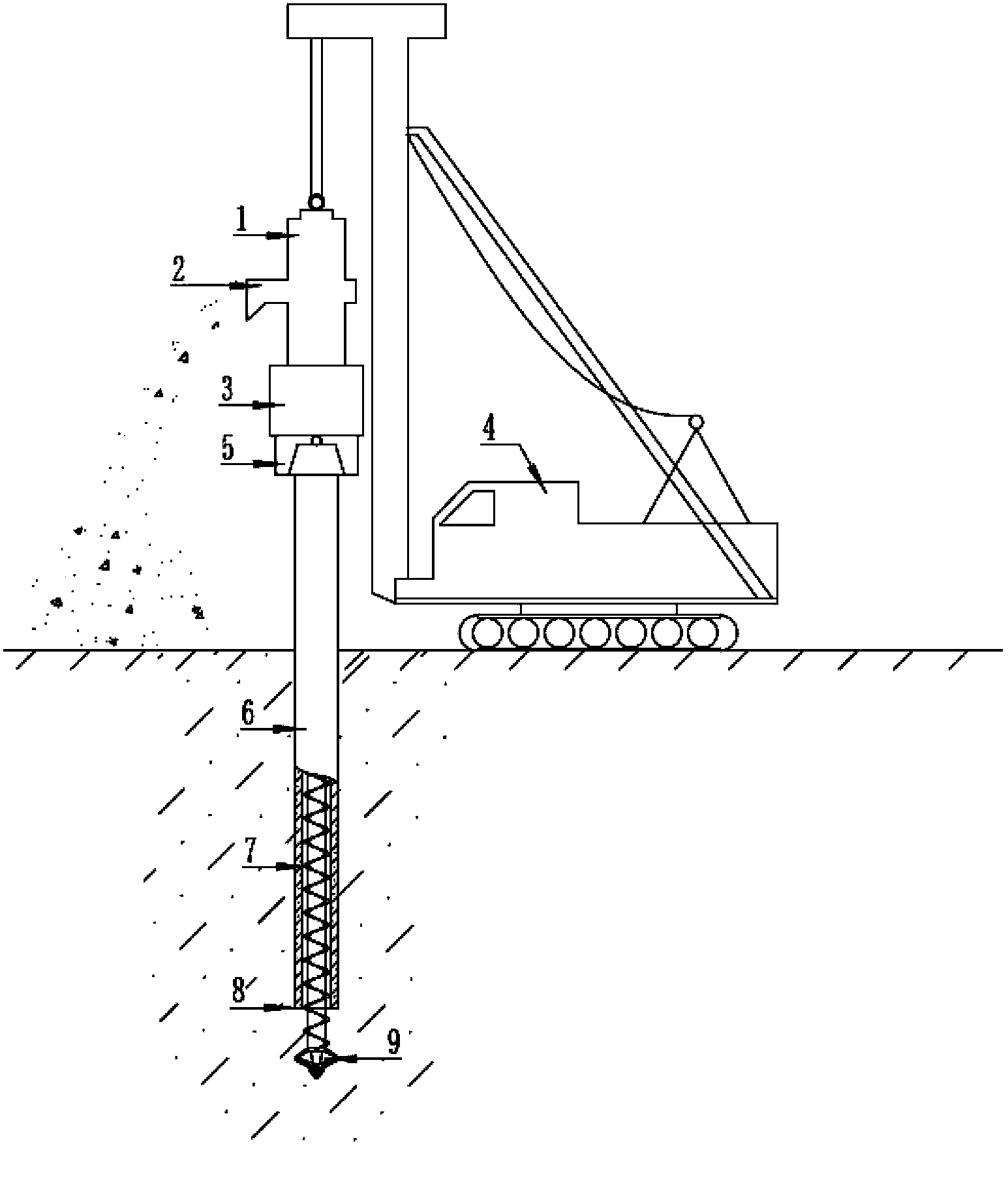

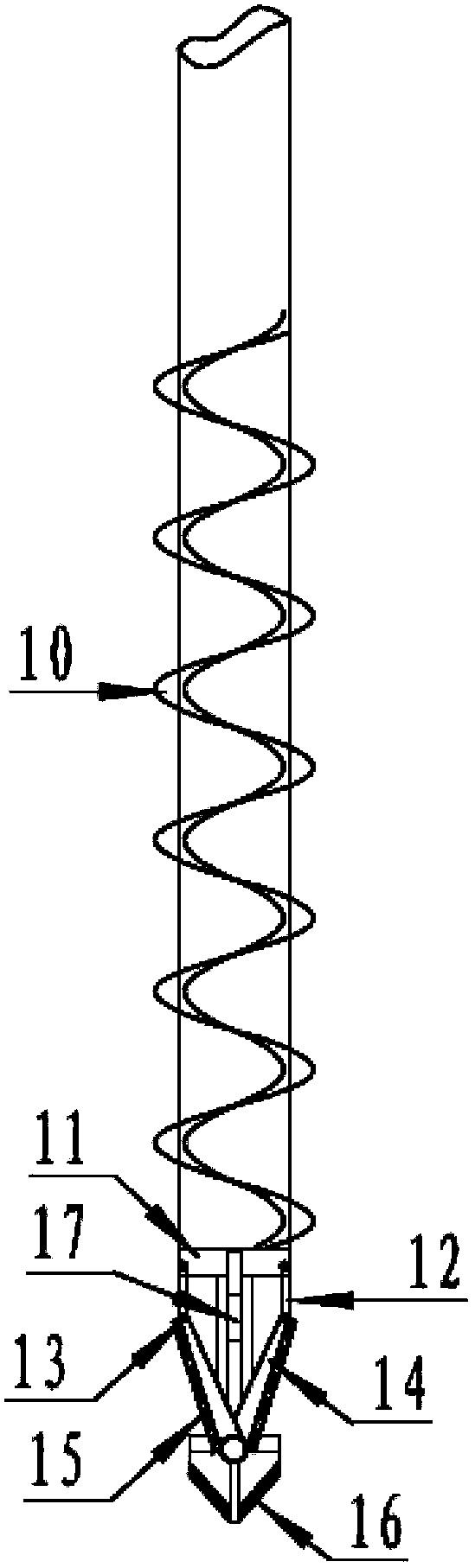

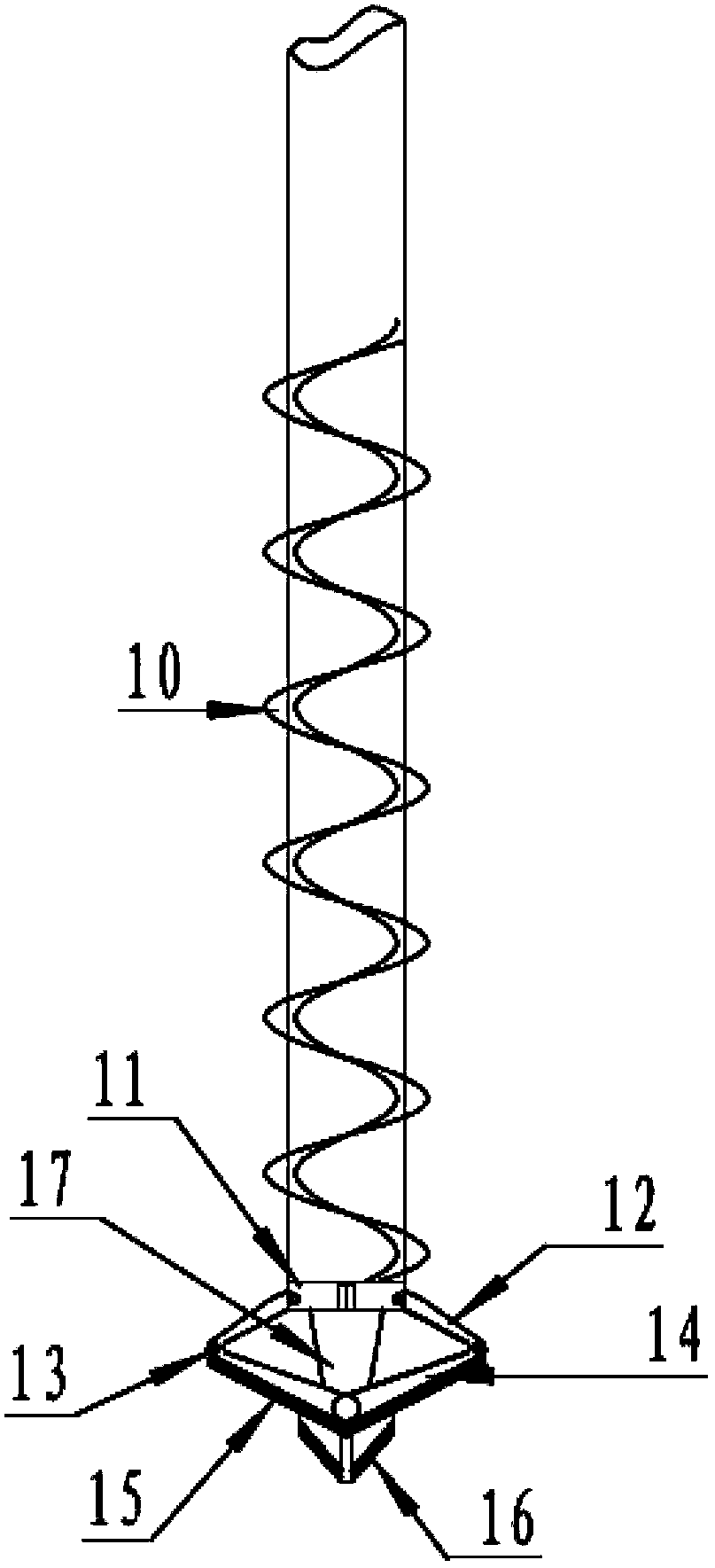

[0023] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail. figure 1 It is a schematic diagram of the construction device of the present invention, figure 2 It is a schematic diagram when the expansion drill bit of the present invention shrinks, image 3 It is a schematic diagram when the expanding drill bit of the present invention is opened.

[0024] Such as figure 1 As shown, a construction device for prefabricated piles is shown in the figure, which includes an auger power head 1, an excavation hole 2, a multifunctional pile hammer 3, a pile driver 4, a chuck 5, a long auger 7, and a prefabricated pile bottom 8. The drill bit 9, the helical piece 10, the auger power head 1 is installed on the pile driver 4, the multifunctional pile hammer 3 is installed on the lower end of the auger power head 1, and the lower end of the multifunctional pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com