Combined down-hole hammer drilling tool and pile forming construction method thereof

A combined DTH hammer and DTH hammer technology can be applied to drill pipes, drill pipes, sheet pile walls, etc., which can solve the problems of low construction efficiency, low gas flow, and high cost, and achieve improved construction speed and simple construction procedures. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing, the present invention will be further described.

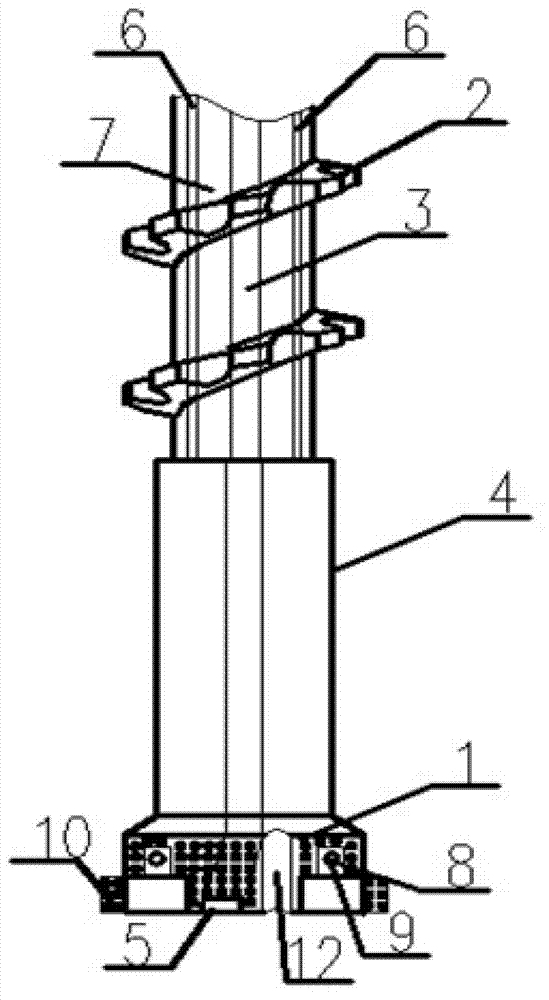

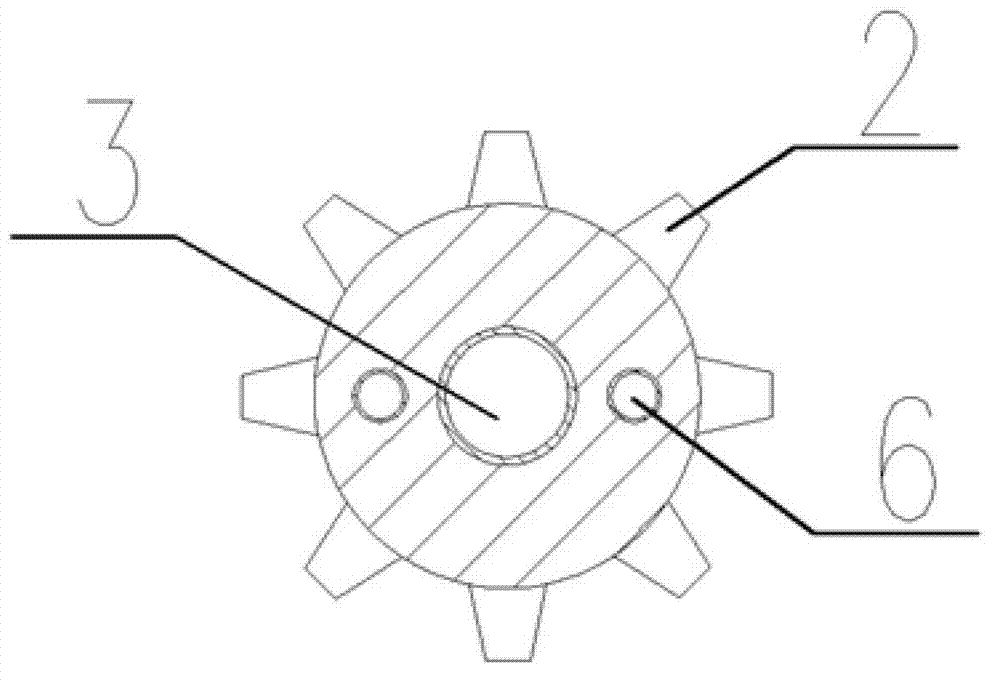

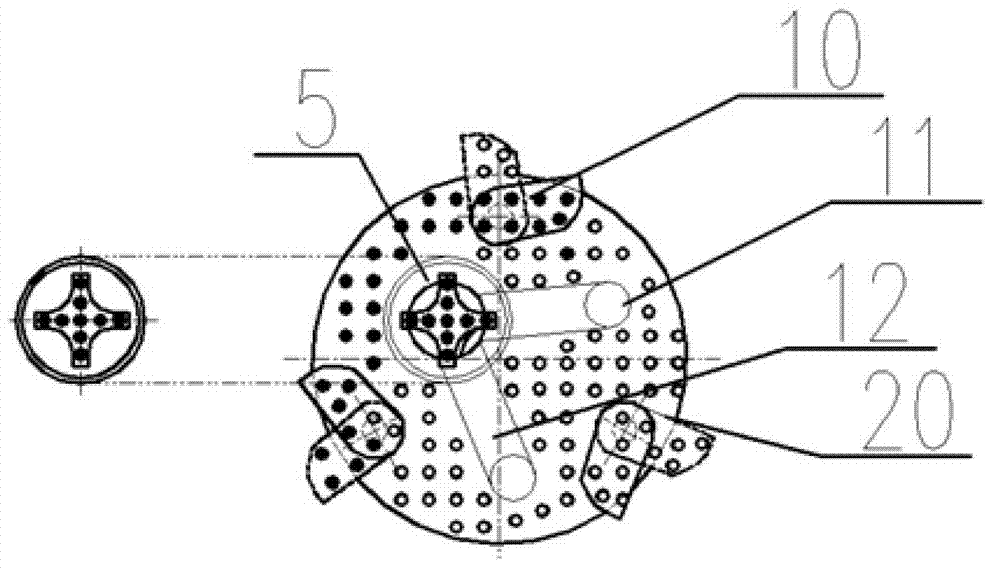

[0055] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 In the shown structure, the combined down-the-hole hammer drilling tool designed by the present invention includes an open-type down-the-hole hammer 1, a multi-layer toothed thread drill rod 2, and the open-type down-the-hole hammer and the multi-layer tooth-shaped thread drill rod pass through the positioning Pin 8, positioning shaft 9 and sealing gasket are fixed; the impactor of described open type down-the-hole hammer is designed as hollow type impactor 4, and the inner diameter of its center hole is greater than the inner diameter of drill pipe inner pipe 3, to facilitate the normal delivery of concrete, When the down-the-hole hammer breaks the rock, the discharged gas and slag are discharged through the center hole of the hollow impactor in reverse circulation. At the bottom of the open-type dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com