Comprehensive pile driver

A technology of pile driver and piling hammer, which is applied in the direction of sheet pile wall, driving device of rotary joint drilling, drilling equipment, etc., can solve the problem of inability to have rotary piling and impact hammer piling at the same time, easy mutual interference in construction, poor protection effect, etc. problem, to achieve the effect of good protection, good driving stability and convenient switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

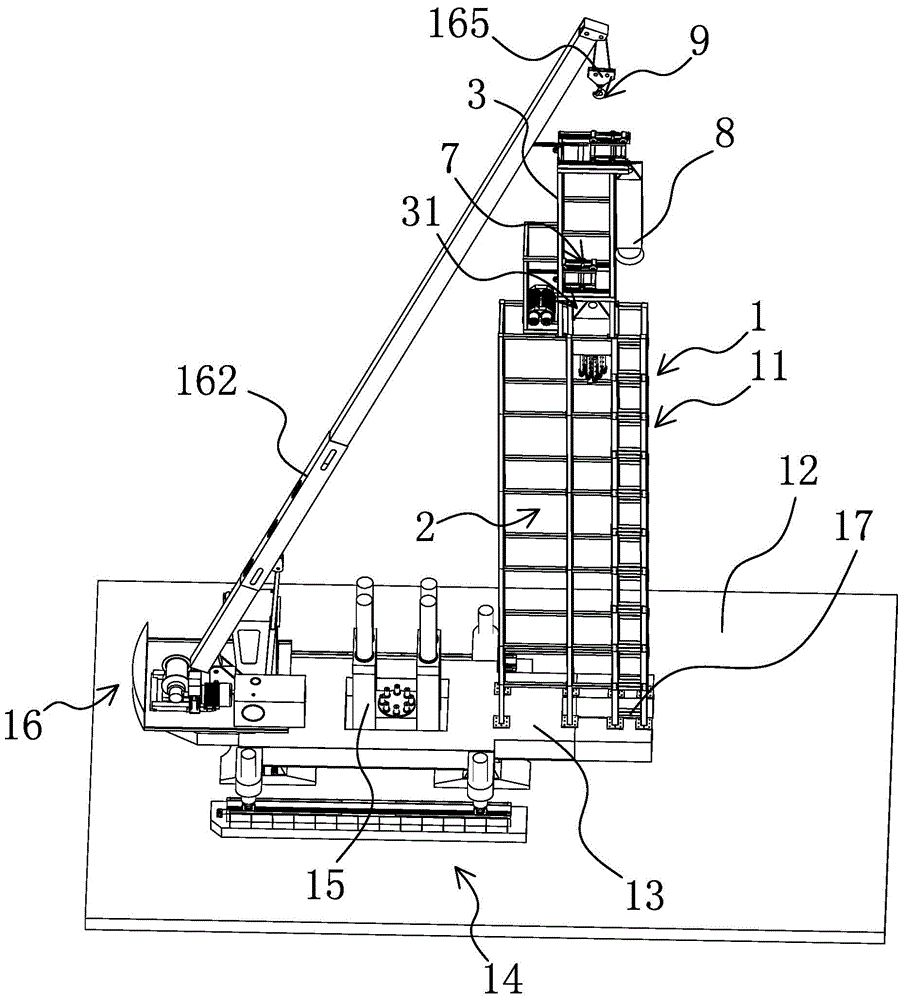

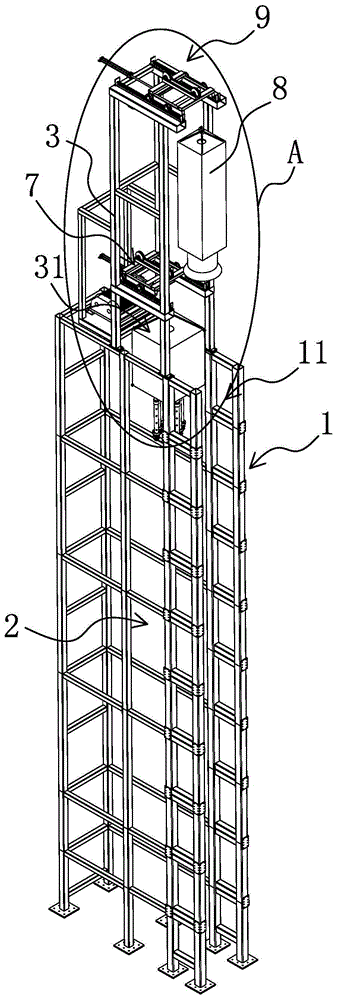

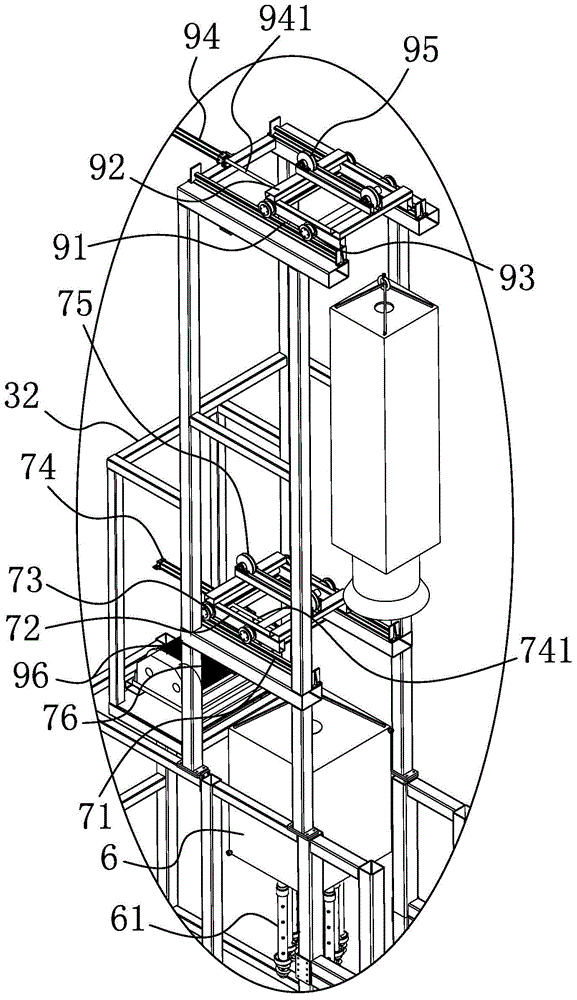

[0031] Such as Figure 1-3 As shown, the integrated piling machine includes a pile-pressing platform 13 horizontally arranged above the ground 12, and between the pile-pressing platform 13 and the ground 12, there is a device capable of driving the pile-pressing platform 13 to move laterally in the horizontal direction and / or to move longitudinally in the horizontal direction. Translation drive structure 14 is provided with piling cap 15 in the middle of pile pressing platform 13. One end of pile pressing platform 13 is provided with lifting structure 16, and the other end is provided with support body 1 arranged along the vertical direction. The vertical direction runs through the construction channel 2 of the whole support body 1, the upper end of the support body 1 is provided with a top frame body 3, and the inside of the top fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com