High-intensity prestressed concrete tubular pile lead hole hammering construction method for soft soil layer

A construction method and prestressing technology, applied in sheet pile walls, foundation structure engineering, foundation structure tests, etc., can solve problems such as machine sinking, static pressure pile machine volume, weight, and roads that cannot be transported, etc., to achieve Save money, shorten the construction period, and improve the effect of shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

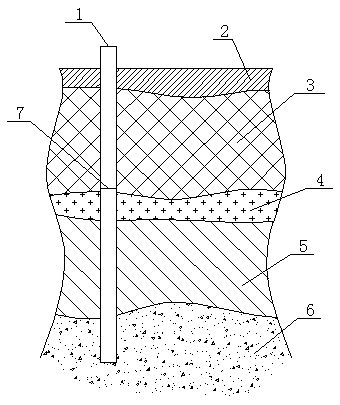

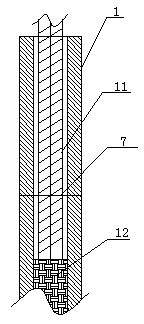

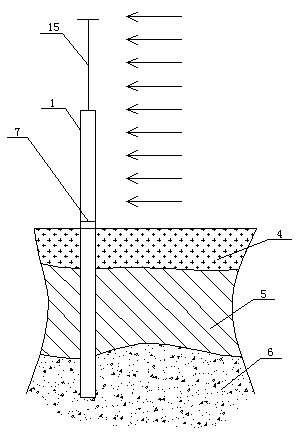

[0024] According to the construction sequence, the high-strength prestressed concrete pipe pile pilot hole hammering construction method in the soft soil layer of the present invention includes measurement and positioning, long auger drilling machine pilot hole construction, guide rod type diesel hammer pile driver construction, hoisting into the steel cage and pouring concrete, etc. Four steps to comply with the requirements of specific engineering design in specific construction.

[0025] The measurement and positioning step is to use the total station to determine the specific pile position control point on the basis of GPS positioning (the pile position control point is mainly located at the corner of the operation route) and pour concrete protection at the control point; finally, use theodolite and A 50m steel ruler is used to locate each pile position to prevent the pile from being damaged; set up no less than 2 control piles and benchmarking points near the piling const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com