Method for forming variable-cross-section compaction thread pile and compaction drilling tool

A technology of variable cross-section and threaded piles, which is applied in earthwork drilling, drilling equipment and methods, drill pipes, etc., and can solve problems such as the small range of pile bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

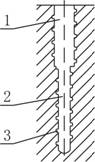

[0039]figure 1 Description of markings: 1 for the upper section of the pile body, 2 for the lower section of the pile body, and 3 for side threads.

[0040] Figure 4 Labeled Description: Compact Drill 4.

[0041] Figure 15 Description of markings: 5 outer drill rods, 6 inner drill rods.

[0042] Figure 16 Explanation of mark: helical rotor 7, bearing pin 8, expanding cutter head 9.

[0043] Figure 17 Explanation of markings: internal spline 10, stopper 11.

[0044] Figure 19 Explanation of marks: external spline 12, concrete door 13, coarse thread 14.

[0045] The implementation of variable cross-section compacted threaded pile forming pile method of the present invention adopts the following process steps:

[0046] ①. Pile driver in place: align the inner drill pipe 6 of the pile driver compaction drilling tool 4 with the position to be piled (see Figure 5 );

[0047] ②. Hole forming in the upper section 1 of the pile body: the inner drill pipe 6 of the pile d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com