Automatic coating technology of large-scale steel pipe anticorrosion coating and production line thereof

A coating production line and anti-corrosion coating technology, applied in pipeline anti-corrosion/rust protection, coatings, devices for coating liquid on the surface, etc., can solve the problems of high operating intensity, long curing time, high internal stress of the coating, etc. problems, to achieve the effect of improving the efficiency of coating operations, high efficiency of coating operations, and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

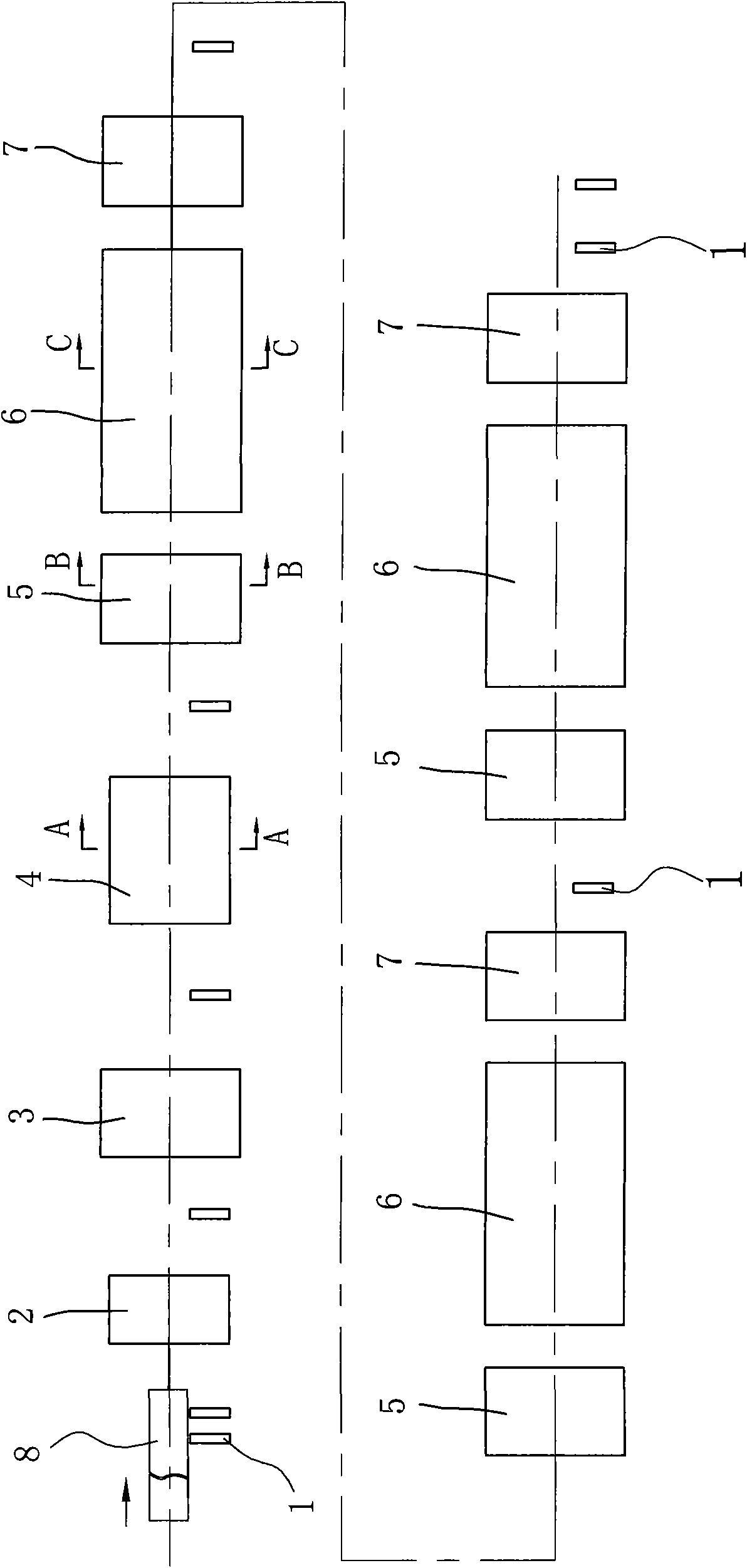

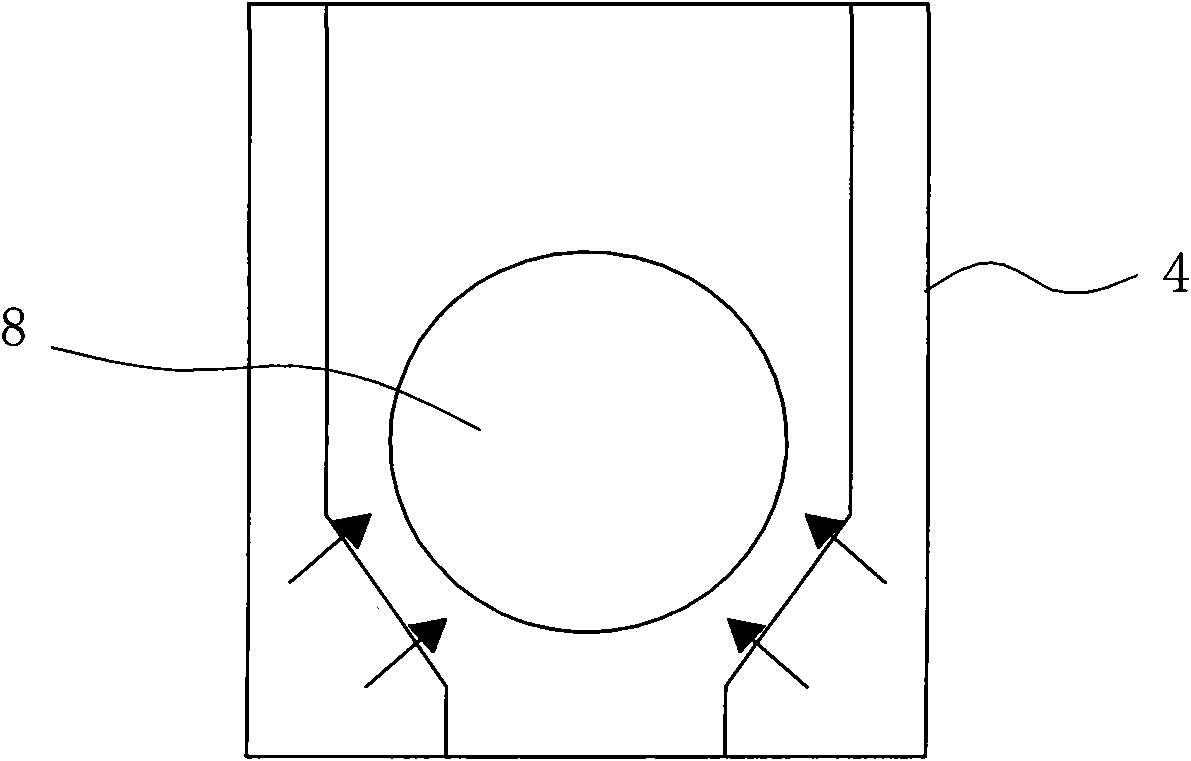

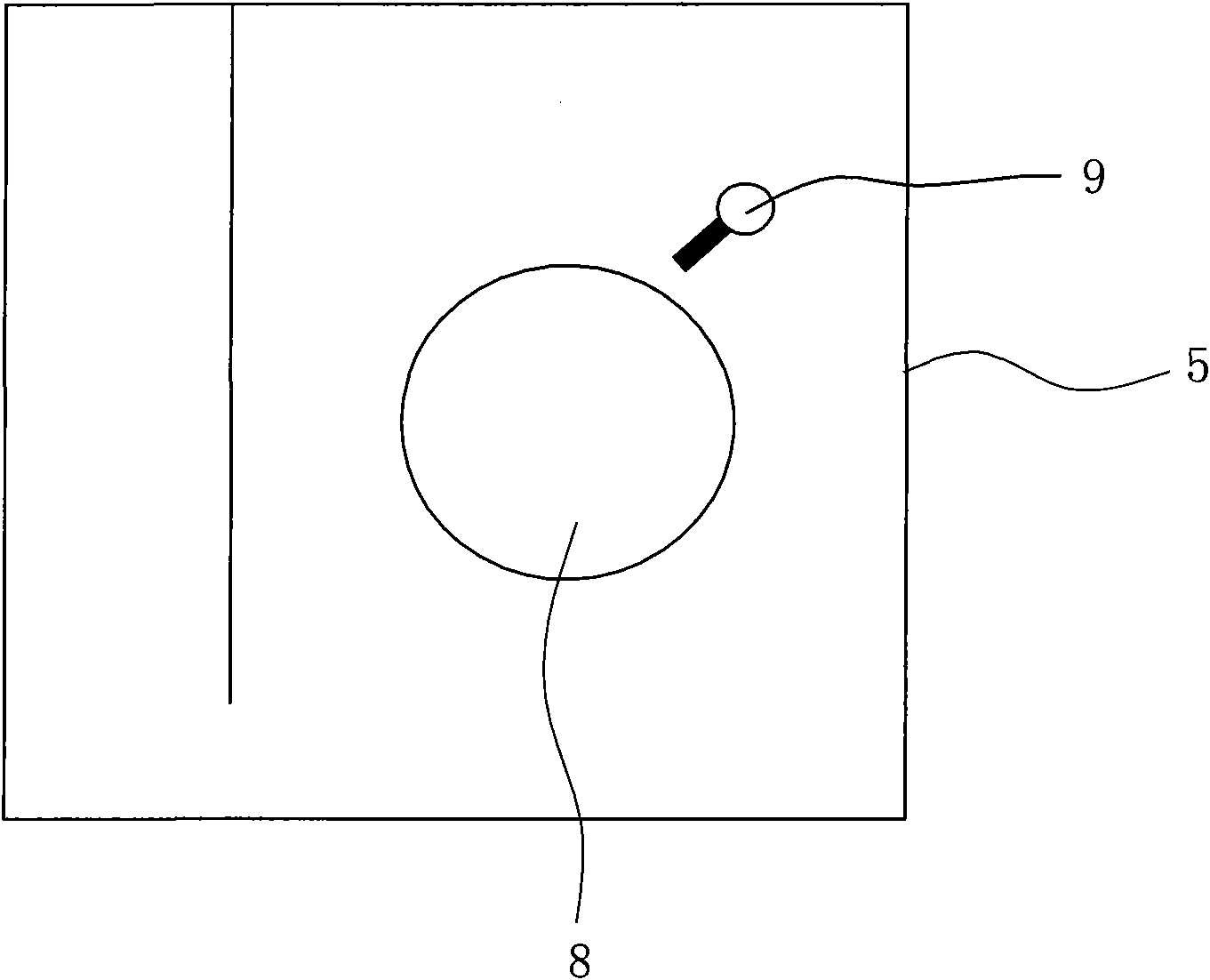

[0034] Such as figure 1 As shown, the large-scale steel pipe anti-corrosion coating automatic coating production line includes: steel pipe transmission mechanism 1, dehumidification and decontamination machine 2, automatic shot blasting machine 3, preheating drying room 4 and a paint spraying room 5, paint film curing room 6 and The paint spray curing unit formed by the cooling room 7 needs to be coated with three coats of primer, intermediate paint and finish paint in this embodiment, so three curing units are arranged in a straight line before and after, that is, the first paint spray curing unit, the second paint spray curing unit and the third spray paint curing unit.

[0035] The steel pipe transmission mechanism 1 described therein includes a plurality of roller groups arranged at intervals and at equal heights, and each roller group is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com