Glass product with cracked color surface and preparation method thereof

A glass product and glass technology, which is applied in the field of glass products with cracked colors and its preparation, can solve the problems of pollution, low efficiency, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

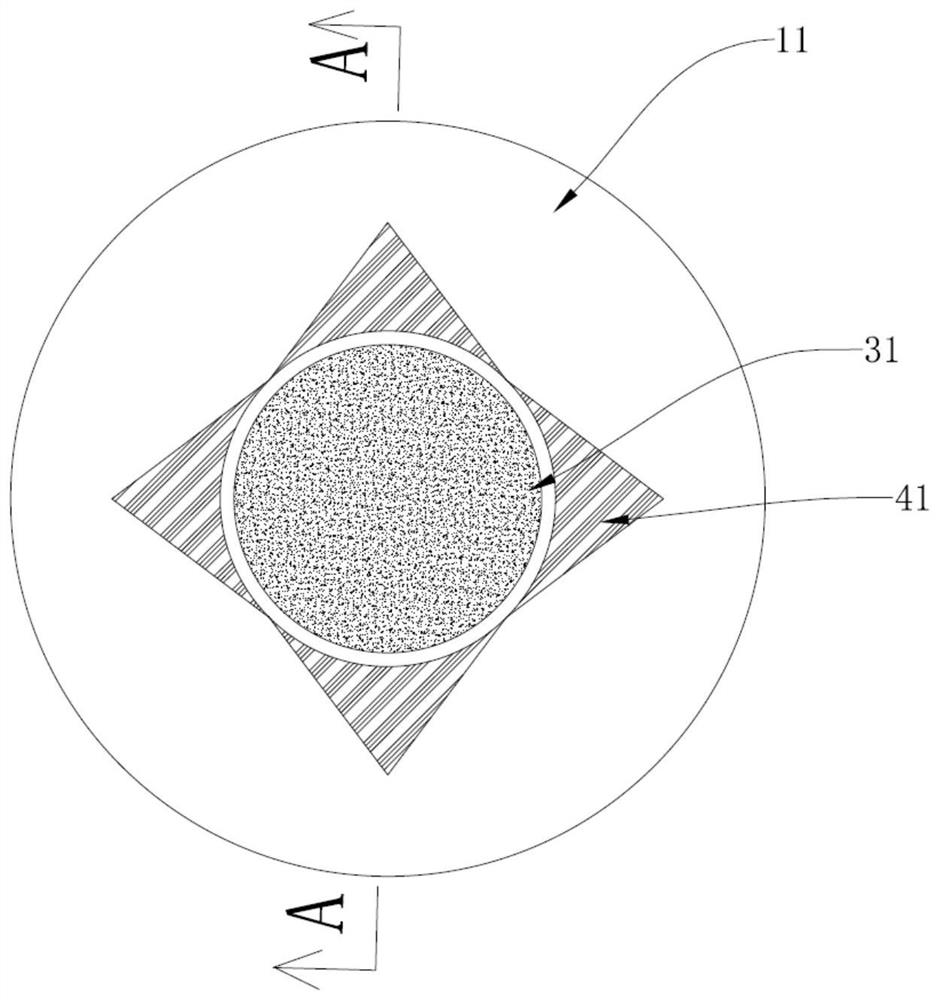

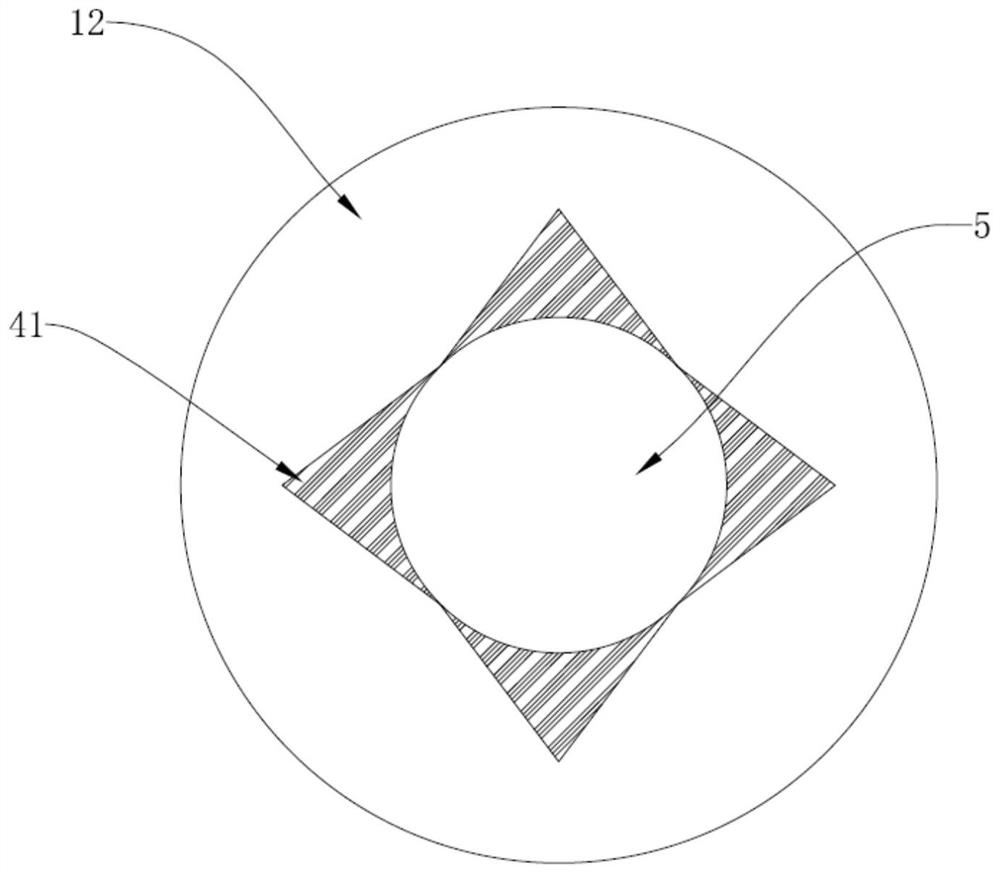

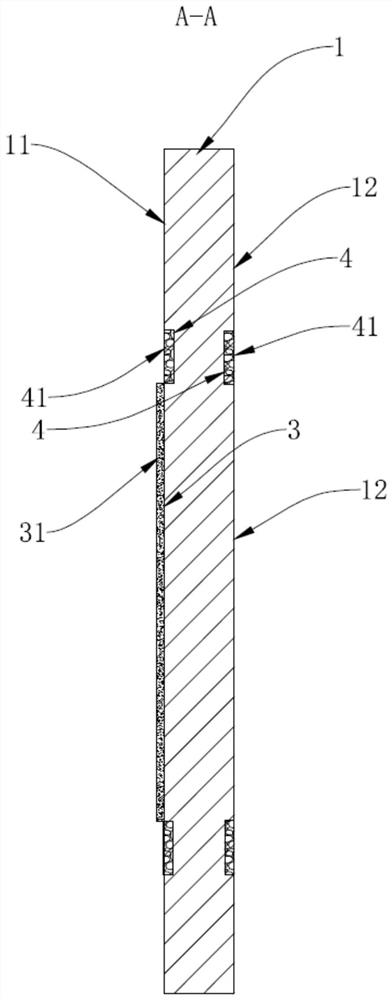

[0028] refer to Figure 1 to Figure 3 , this embodiment provides a glass product with cracked color on the surface, including a glass body 1, the glass body 1 is transparent glass, and the glass body 1 can be designed as a circle, an ellipse or a square according to actual needs. In this embodiment, The glass body 1 is in the shape of a flat disc. The glass body 1 includes a front 11 and a back 12. The front 11 and / or the back 12 are provided with at least one first region 3, which is arranged on the front 11 of the glass body 1 in this embodiment. There is a first area 3, and a first engraving pattern is provided on the first area 3, and a crack color pattern 31 is provided on the first engraving pattern.

[0029] The first area 3 can be a large area, or it can be a patchwork of multiple areas. At least one planar shape of the first area 3 is carved into a designed pattern, such as the shape of a landscape painting, and the carving is carried out inside the first area 3. , a...

Embodiment 2

[0034] This embodiment provides a method for preparing glass products with cracked colors on the surface, comprising the following steps:

[0035] Step S1, performing sandblasting engraving or erecting lines on the front side 11 and / or back side 12 of the glass body 1 to form the first region 3;

[0036] Step S2, adding ice paint in the first area 3;

[0037] Step S3, placing the glass body in a cool environment, adjusting the ambient temperature and humidity, and controlling the size of the ice flower;

[0038] Step S4, air drying and curing.

[0039] It should be noted that the front side 11 and / or the back side 12 of the transparent and smooth glass body 1 are processed. The processing process is sandblasting engraving or vertical line, wherein the engraving process adopts an environmentally friendly sandblasting engraving machine for single-sided or double-sided engraving. Surface engraving, under the pressure of 0.6 ~ 0.8MPa, use 150-mesh white corundum to perform singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com