Device and method for immovable-string type packer-free sliding-sleeve hydraulic-jet pulsed acid fracturing

A technology of hydraulic jetting and sliding sleeve, which is used in drilling pipes, casings, and earth-moving drilling and mining, etc., can solve the problems of the packer being corroded by acid liquid, the sealing effect is deteriorated, and the crack length is limited, and the construction method is mature. , The effect of reducing operation time and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

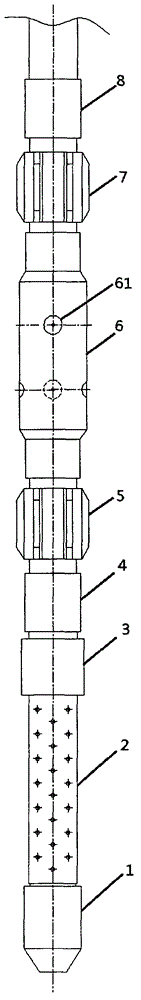

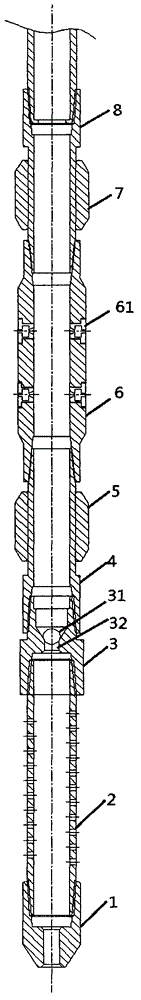

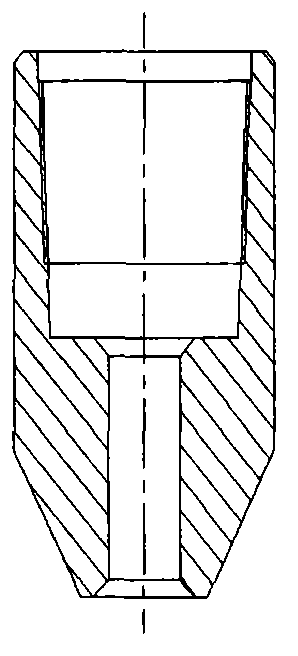

[0060] As shown in Fig. 1, the first-stage non-moving string type non-packer sliding sleeve hydrojet pulsating acid fracturing device used when fracturing only the first-stage formation includes a guide head 1, a porous tubing nipple 2, and a one-way valve 3 , the first lower joint 4, the first centralizer 5, the first spray gun 6, the second centralizer 7, the first upper joint 8; from bottom to top, the guide head 1 is connected to the lower end of the porous tubing joint 2, and the guide The head 1 can ensure the smooth running of the tool into the well, and at the same time cooperate with the porous tubing nipple 2 to provide a flow channel for backwashing the wellbore; There are valve balls 31 and ball seat valves 32, which are used to realize the sealing of the non-moving string type non-packer sliding sleeve hydraulic jet pulsating acid fracturing device during acid fracturing and the opening of the tool channel during backwashing cycle operations; one-way The upper end...

Embodiment 2

[0071] As shown in Fig. 10, the two-stage non-moving string-type sliding sleeve hydraulic jet pulsating acid fracturing device used in fracturing two-stage formations is different from the two-stage non-moving one used in the first-stage formation in Example 1. The difference of the string-type non-packer sliding sleeve hydrojet pulsating acid fracturing device is that it also includes the second spray gun 9 and the second upper sub-joint 10; the upper end of the second spray gun 9 is connected to the working string through the second upper sub-joint 10 , the lower end is connected with the upper end of the first upper nipple 8; the second spray gun 9 is designed with a sliding sleeve 93 and a pin 92, and when performing the first-stage acid fracturing, the sliding sleeve 93 is fixed by the pin 92, sealing the second spray gun 9 The nozzle is used to carry out the first-stage acid fracturing only through the first spray gun 6; after the first-stage acid fracturing is completed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com