Drag type packer-less hydraulic jet pulsating acid fracturing device and method

A technology of hydrojet and acid fracturing, which is applied in the direction of earthwork drilling, production fluid, drilling equipment, etc., can solve the problems of poor isolation effect, packer corrosion, sand stuck pipe string downhole accidents, etc., and achieve low construction cost , Simple device structure and mature construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

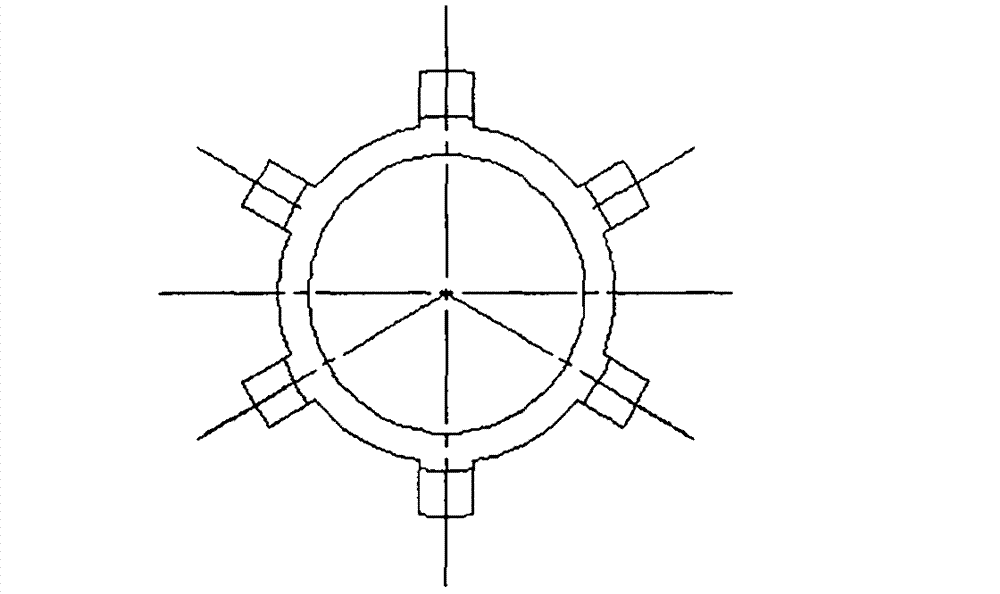

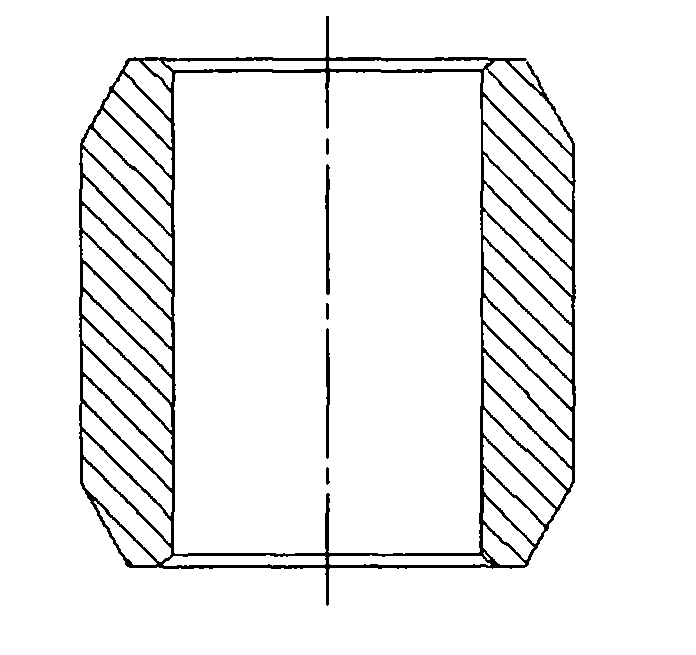

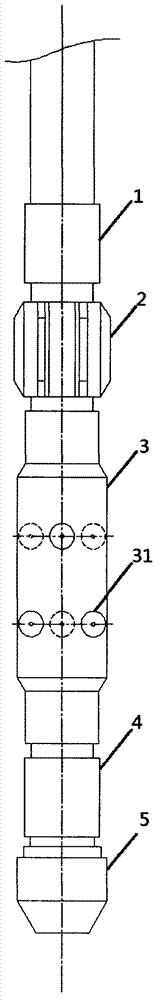

[0043]As shown in Figure 1, the drag-type packer-less hydraulic jet pulsating acid fracturing device includes an upconversion sub 1, a centralizer 2, a spray gun 3, a downconversion sub 4, and a guide joint 5; the upper end of an upconversion sub 1 It is connected with the construction pipe string, and the lower end is connected with the upper end of the spray gun 3, and the lower end of the spray gun 3 is connected with the guide joint 5 by using the lower transfer nipple 4; the centralizer 2 is set on the upper transfer nipple 1, and the centralizer 2 is used for fixed dragging A packer-free hydraulic jet pulsating acid fracturing device, which is located in the center of the wellbore and does not contact the casing, ensures the symmetry and operation stability of the acid fracturing; the spray gun 3 is equipped with a self-excited oscillation nozzle 31 for realizing hydraulic pressure. Jet pulsating perforation and acid fracturing; a ball seat is provided in the guide joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com