Logistics center storage position allocation method

A distribution method and technology of a logistics center, applied in the field of logistics, can solve the problems of reduced equipment utilization, low operation efficiency, high no-load rate and half-load rate of conveying equipment, and achieves improved operation efficiency, reduced operation time, and fewer parking times. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

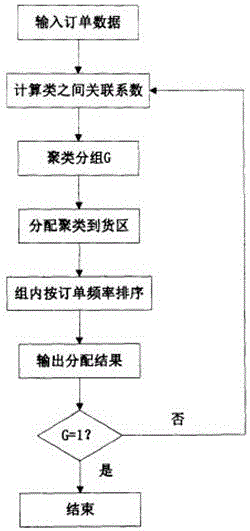

Method used

Image

Examples

Embodiment 1

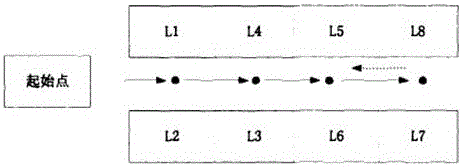

[0083] Assume that the picking form of the warehouse pickers in the lane is as follows: figure 2 As shown, the distance from the entrance to the first storage space is one unit, and the distance between different storage positions is also one unit. The black dot in the figure indicates the point where picking stops. At this point, two lanes can be picked. side shelves, regardless of distance. Table 1 gives 10 orders, and the types and quantities of goods required in the orders are randomly generated.

[0084] Table 1 Order Details

[0085]

[0086] For example, in order A, there are 4 kinds of goods that are goods (1, 2, 3, 4), and the corresponding goods quantities are 5, 4, 3, and 2 respectively. The total number in the table refers to the total quantity of goods 1 contained in 10 orders; the number of times indicates the number of times goods 1 appears in 10 orders; the number of goods in an order refers to the number of goods picked in each order; contains The type ...

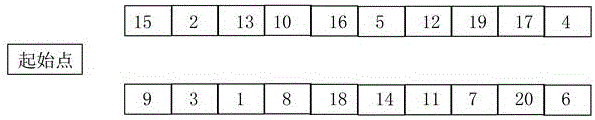

Embodiment 2

[0110] Statistical analysis of company A's order information in the year, sort the order quantity from large to small, and select the top 25 orders, as shown in Table 6, each order contains goods with a quantity between 5 and 11, and all orders Contains 20 types of goods.

[0111] Table 6 Order Details

[0112]

[0113] For this case, the idea of clustering is combined with the model for algorithm design, and finally fine-tuning is carried out on the basis of the results. The final results are shown in Table 7.

[0114] Tab.2-8 Result of Clustering

[0115]

[0116] According to the classification results, it was found that:

[0117](1) The results of dividing 20 kinds of goods into 1 category and 20 categories are the same. The reason is that the allocation of cargo space is carried out according to the order frequency;

[0118] (2) The total picking distance from category 1 to category 4 increases gradually, because the order frequency of goods 4 and 6 is relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com