Welding robot control method

A welding robot and control method technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Operation space limitation and other problems, to achieve the effect of simplifying the teaching process, shortening the movement, i.e. empty distance, and strong anti-electromagnetic field interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

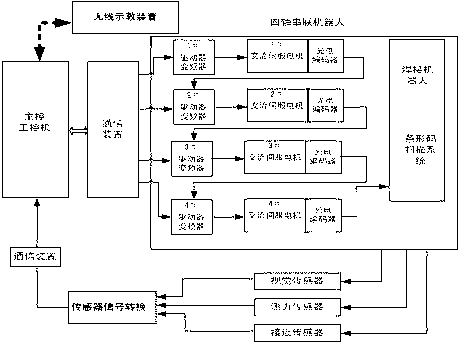

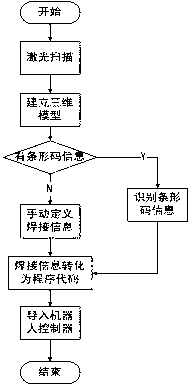

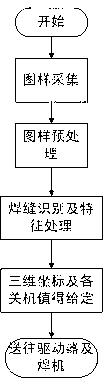

[0030] Such as figure 1 As shown, the welding robot control method is used to detect the sensors of various states of the robot, monitor the force state, rotation angle and speed of each arm of the robot in real time, and capture the information of the welding seam at the same time to form a closed-loop control of the robot.

[0031] The signal conversion device, the sensor converts various signals detected and transmits them to the industrial computer through the communication device. The main industrial computer receives the signal from the wireless teaching device for analysis and processing and completes the human-computer interaction function. The main industrial computer receives the signals from various sensors and performs mechanical calculations, and the control system solves the calculation to form a control error signal. The driving device is used to drive the robot to work by receiving the command sent by the main industrial computer. The wireless teaching device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com