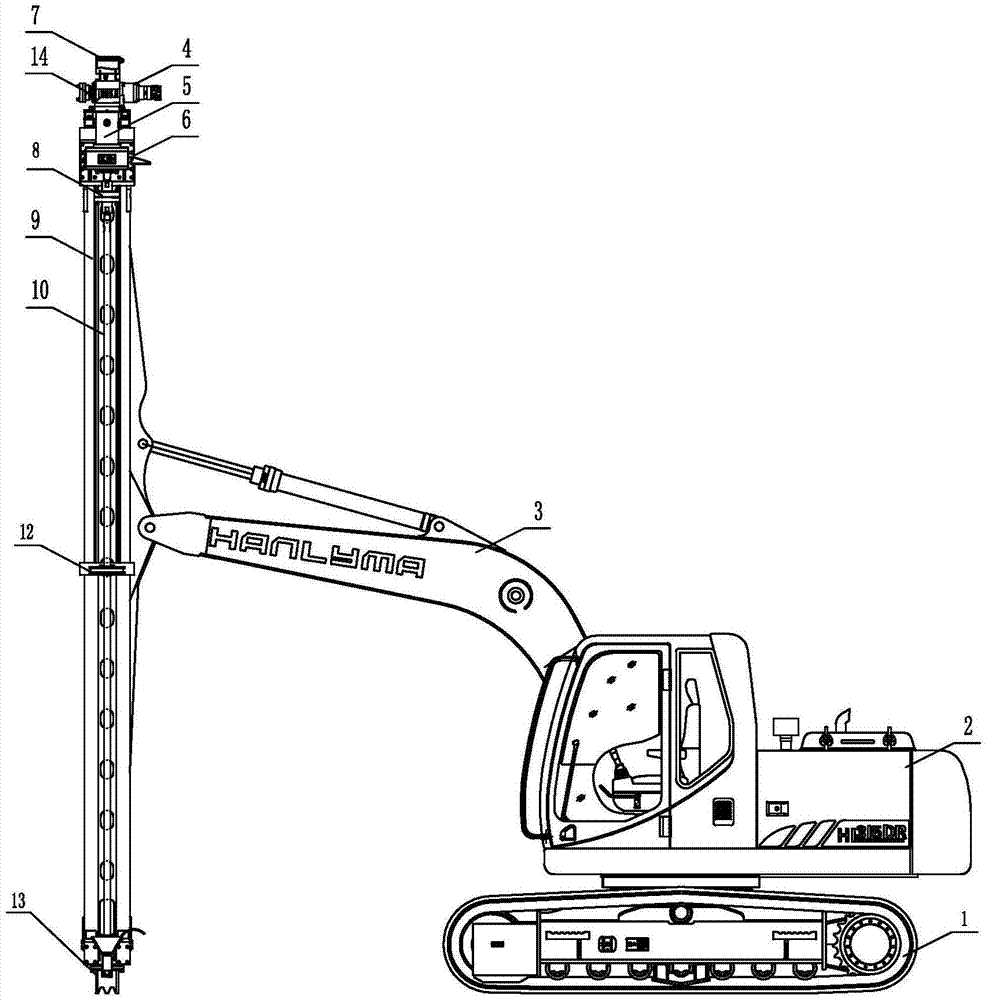

Double-speed double-torque crawler type hydraulic cutting drilling machine

A crawler-type, drilling rig technology, applied in rotary drilling rigs, impact drilling, rotary drilling and other directions, can solve the problems of unstable gas supply, high maintenance costs, short service life of air compressors, etc. The effect of stable air volume, low maintenance and replacement cost, and saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

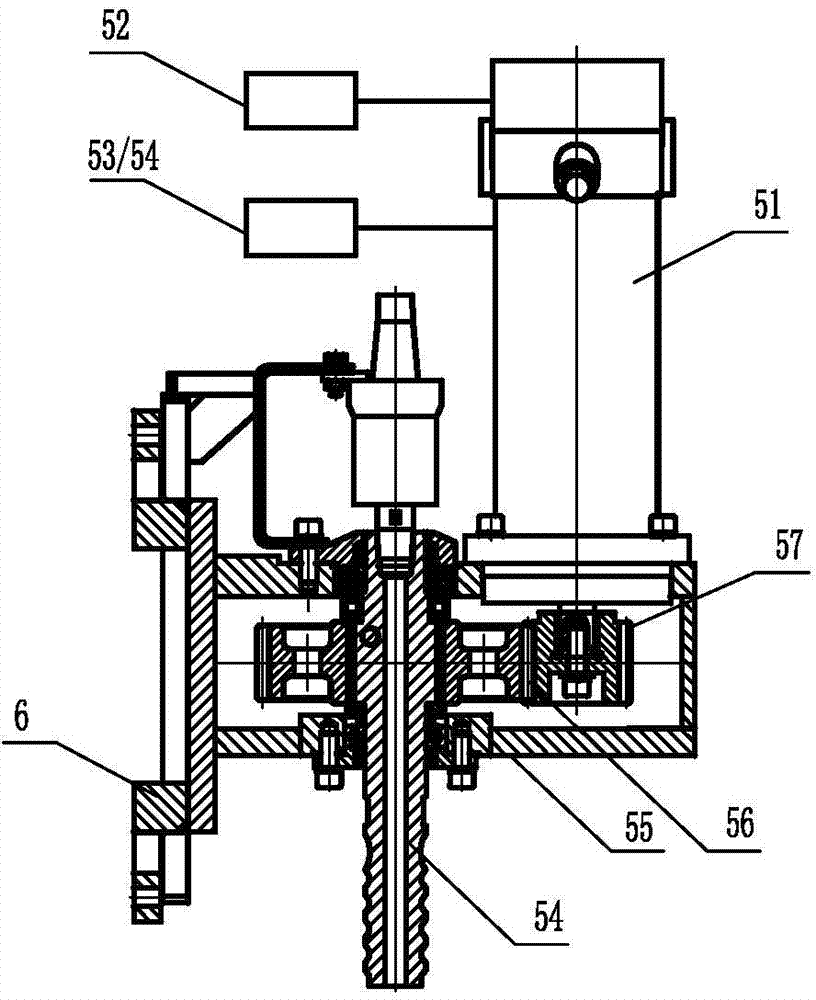

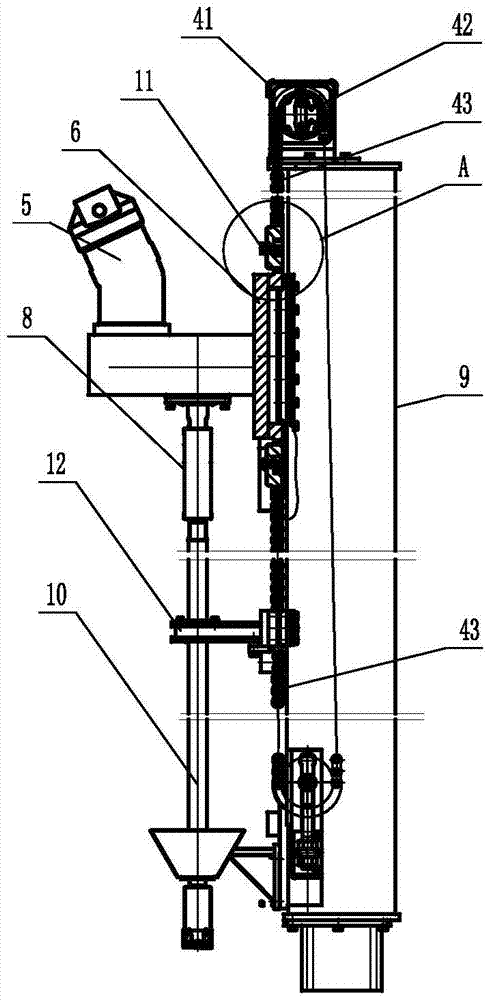

[0046] A double-speed, double-torque crawler-type hydraulic cutting drilling rig, including a boom 3, a drill boom 9 connected to the boom, a power head 5, a propulsion mechanism 4, an air compressor system 2 and a pressure oil source, and the propulsion mechanism is installed On the drill arm, the power head is installed on the guide rail of the drill arm, and the cutting motor 51 installed in the power head is connected to the power head shaft 54 and the drill pipe 10 through the gearbox assembly. The feeding and lifting of the drill pipe is driven by the drive; the main components of the air compressor system are installed on the body of the drilling rig, and communicate with the blowing pipeline of the drilling arm through the pipeline installed on the arm of the drilling rig;

[0047] The power head 5 is equipped with a two-speed, two-torque control device 52 and a drill pipe rotation control device. The two-speed, two-torque control device 52 includes a variable solenoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com