Cement concrete pavement structure provided with continuous steel bars

A technology of cement concrete and pavement structure, applied in the direction of coagulating pavement, road, road, etc. paved on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The described embodiments are only used to illustrate the technical solutions of the present invention, and are not intended to limit the present invention.

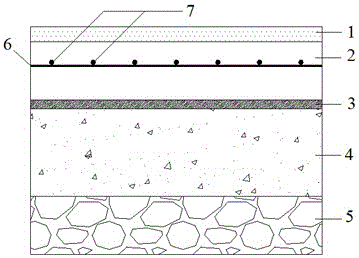

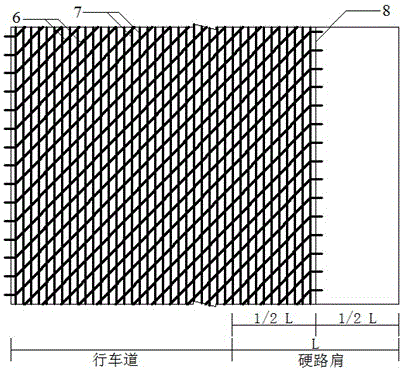

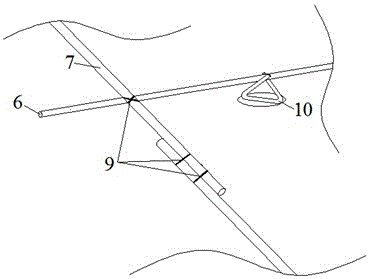

[0020] Such as Figures 1 to 4 As shown, the cement concrete pavement structure of the present invention is provided with continuous steel bars, including rubber cement concrete upper layer 1, cement concrete lower layer 2 with continuous steel bars, asphalt concrete anti-scour layer 3, roller compacted concrete base 4, gravel cushion 5.

[0021] Among them, the upper layer 1 of rubber cement concrete has a thickness of 5cm, a standard value of bending and tensile strength of 5.0MPa, and a rubber powder content of 20kg / m 3 , the rubber powder particles are 60 meshes, and the horizontal induction slits 11 with a length of 50 cm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com