Deflection-swinging type semi-automatic rod replacing hydraulic rock drilling machine

A rock drilling rig, semi-automatic technology, applied in drill pipe, drill pipe, earthwork drilling and other directions, can solve the problems of large vibration, endanger personal safety, high production cost, achieve simple and reasonable structure, reduce safety hazards, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

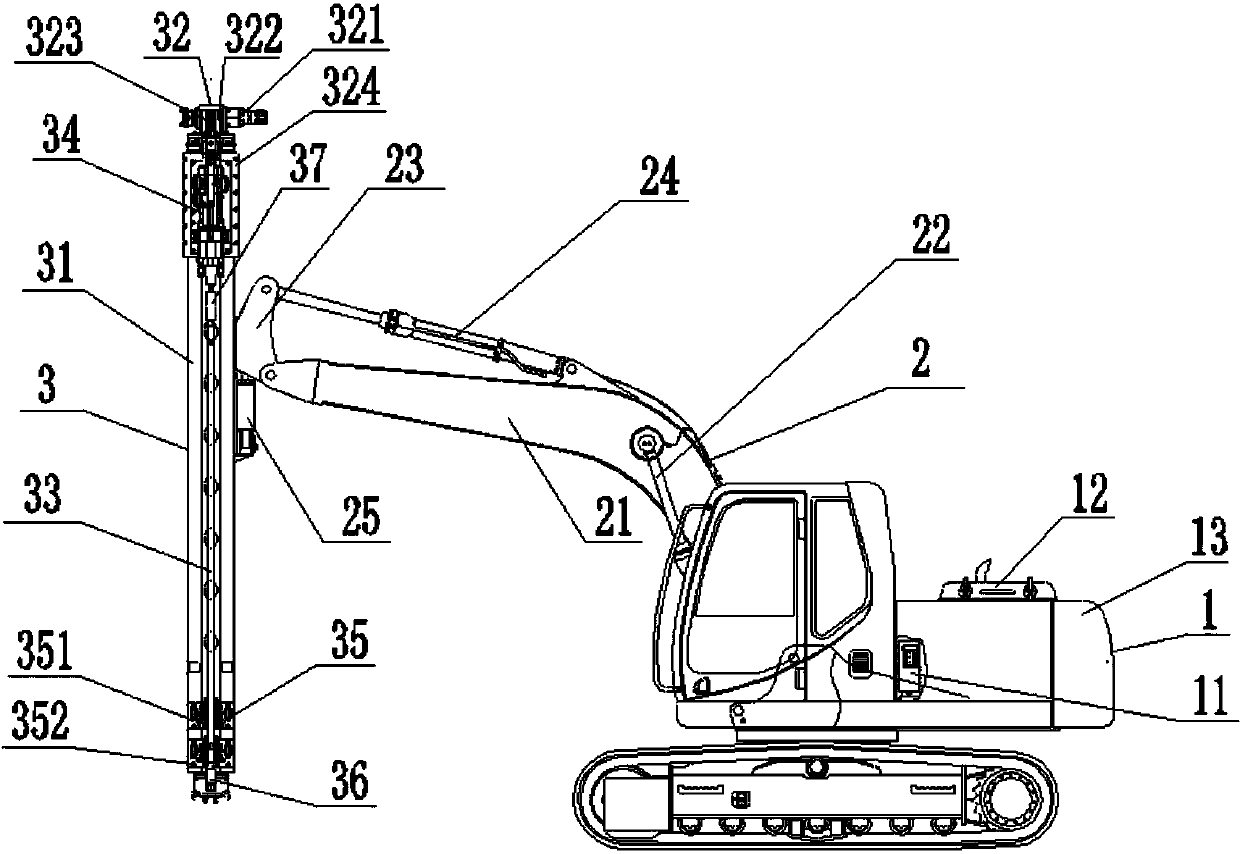

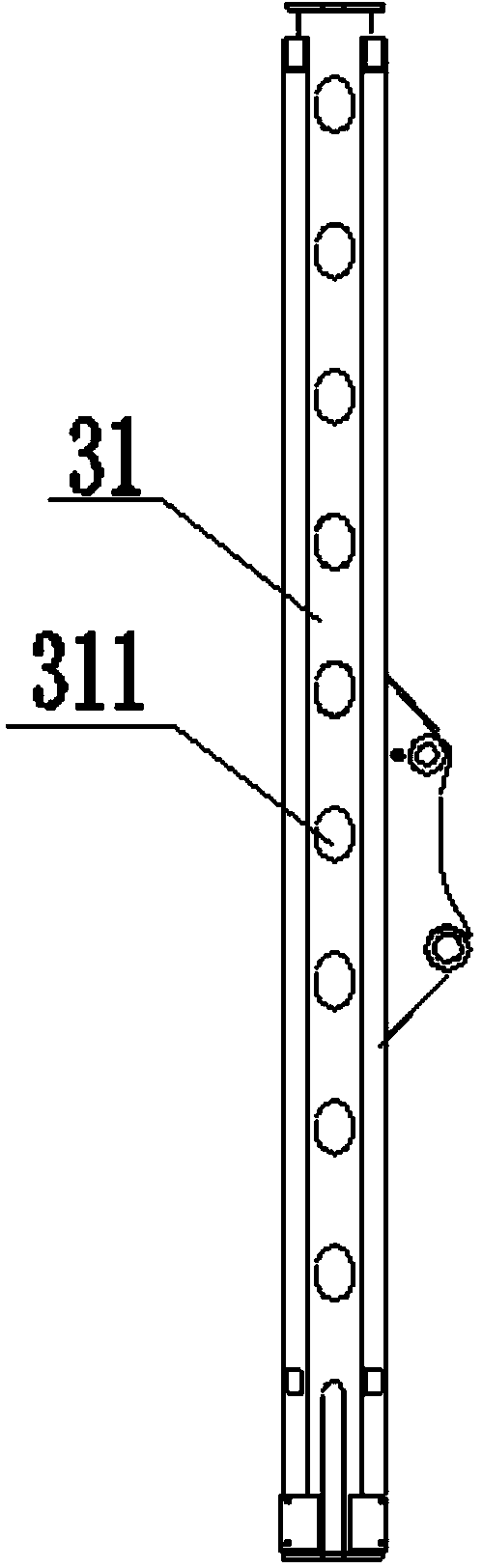

[0040] Such as Figure 1 to Figure 6 As shown, a deflection type semi-automatic rod-changing hydraulic rock drilling rig includes a carrier machine 1, a boom 2 and a drilling machine 3. One end of the boom 2 is placed on the upper end of the carrier machine 1, and the boom 2 The other end of is connected to the middle of the drill 3, and the boom 2 drives the drill 3 to deflect;

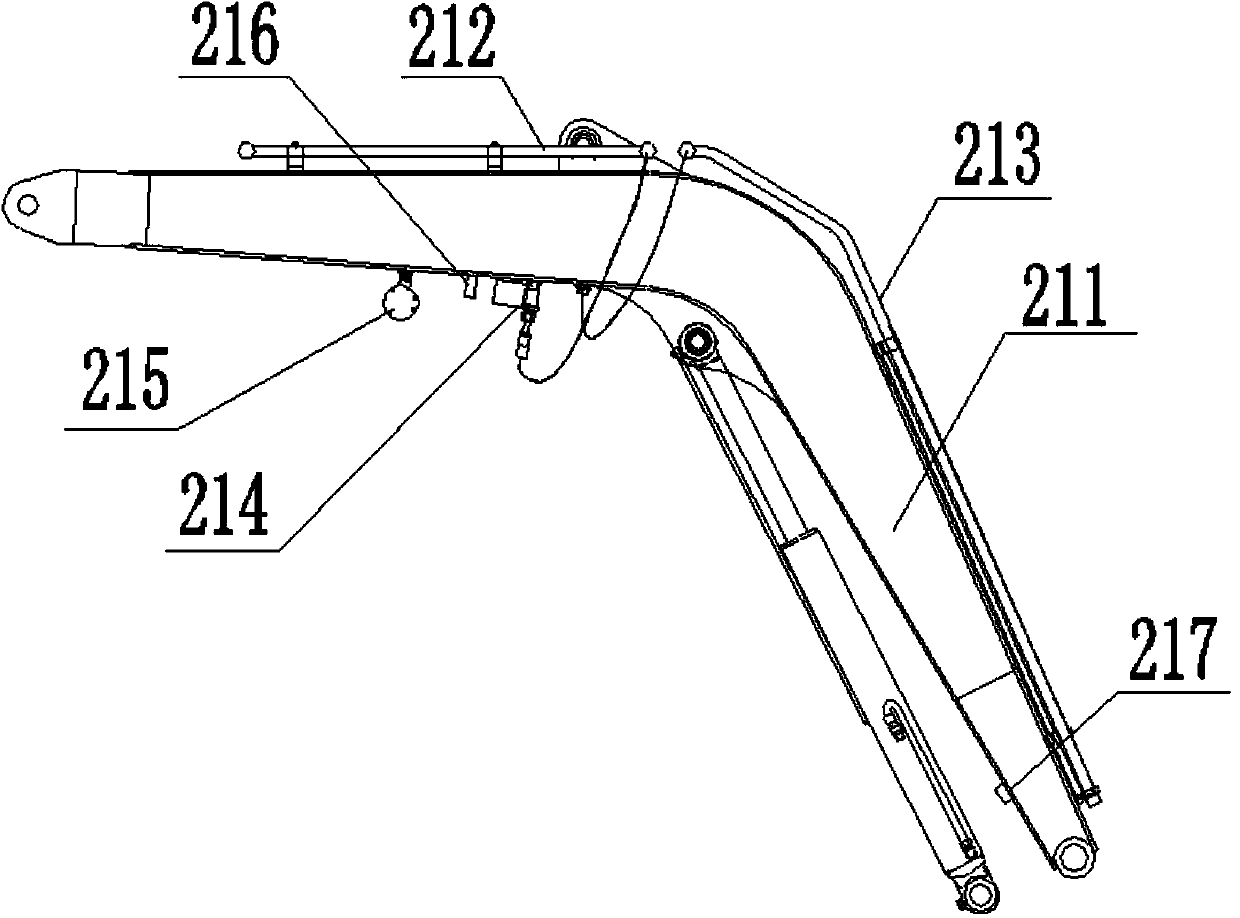

[0041] The boom 2 includes a boom body 21, a boom cylinder 22, a turntable 23, a boom cylinder 24, and a yaw cylinder 25. One end of the boom body 21 is connected to the carrier machine 1, and the boom cylinder One end of 22 is also connected to the carrier machine 1, the other end of the boom cylinder 22 is connected to the bend of the boom body 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com