Vibration reduction turnout pedestal system and assembly method

A technology of switch and base, applied in the field of vibration damping switch base system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

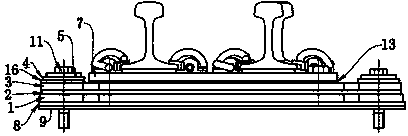

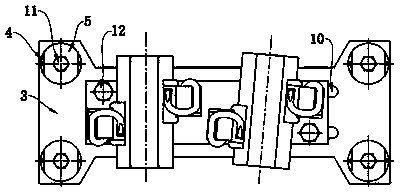

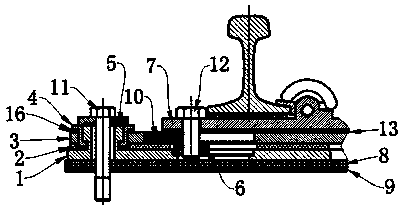

[0072] combine figure 1 , 2 , 3. A vibration-damping turnout base system, the vibration-damping turnout base system includes a lower base plate (1), an intermediate elastic insulating pad (2), an upper base plate (3) and a switch fastener base (7); The vibration-damping turnout base is provided with a distance-adjustable connection positioning assembly for connecting the upper base plate (3) and the turnout fastener base (7) into one; the turnout fastener base (7) has a switch fastener base through hole (7.1), the upper base plate (3) has an upper guide chute (3.2) corresponding to the through hole (7.1) of the turnout fastener base, and the upper guide chute (3.2) of the upper base plate is a through upper base plate ( 3) through-hole structure; the distance-adjustable connection positioning component passes through the through hole (7.1) of the turnout fastener base and the upper guide chute (3.2) of the upper bottom plate (3), so that the upper bottom plate (3) and the tu...

Embodiment 2

[0099] combine figure 1 , 11 , 20. A vibration damping turnout base system, the vibration damping turnout base system includes a lower base plate (1), an intermediate elastic insulating pad (2), an upper base plate (3) and a switch fastener base (7); The vibration-damping turnout base is provided with a distance-adjustable connection positioning assembly for connecting the upper base plate (3) and the turnout fastener base (7) into one; the turnout fastener base (7) has a switch fastener base through hole (7.1), the upper base plate (3) has an upper guide chute (3.2) corresponding to the through hole (7.1) of the turnout fastener base, and the upper guide chute (3.2) of the upper base plate is a through upper base plate ( 3) through-hole structure; the distance-adjustable connection positioning component passes through the through hole (7.1) of the turnout fastener base and the upper guide chute (3.2) of the upper bottom plate (3), so that the upper bottom plate (3) and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com