Tapping flow control method and system for full-automatic converter tapping

A flow control and control system technology, which is applied in the direction of manufacturing converters, special data processing applications, instruments, etc., can solve the problems of tapping time fluctuation, molten steel overflow, improper operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] In the following, the method and system for controlling the tapping flow rate of the converter fully automatic tapping described in the present invention will be further explained and illustrated in conjunction with the accompanying drawings and specific embodiments of the specification. However, such explanations and illustrations do not constitute inappropriate technical solutions of the present invention. limited.

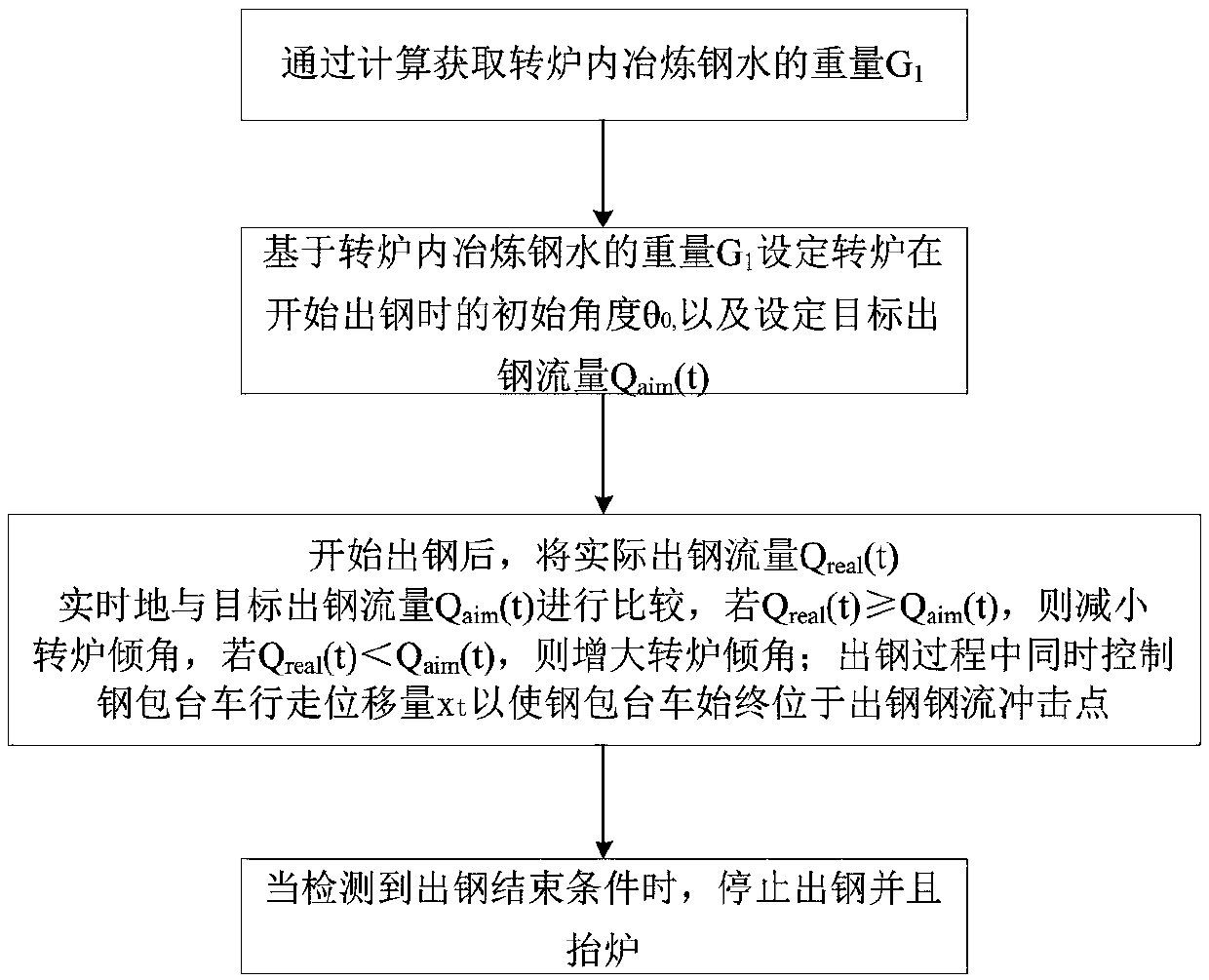

[0074] figure 1 It is a schematic flow chart of the method for controlling the tapping flow rate of the converter fully automatic tapping described in the present invention in one embodiment.

[0075] Such as figure 1 As shown, in this embodiment, the tapping flow control method includes the following steps:

[0076] (1) Obtain the weight G of molten steel smelted in the converter by calculation 1 ;

[0077] (2) Set the initial angle θ of the converter at the beginning of tapping based on the weight of molten steel in the converter 0 ; and set the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com